Feedforward and ratio control

In class activities

Activities

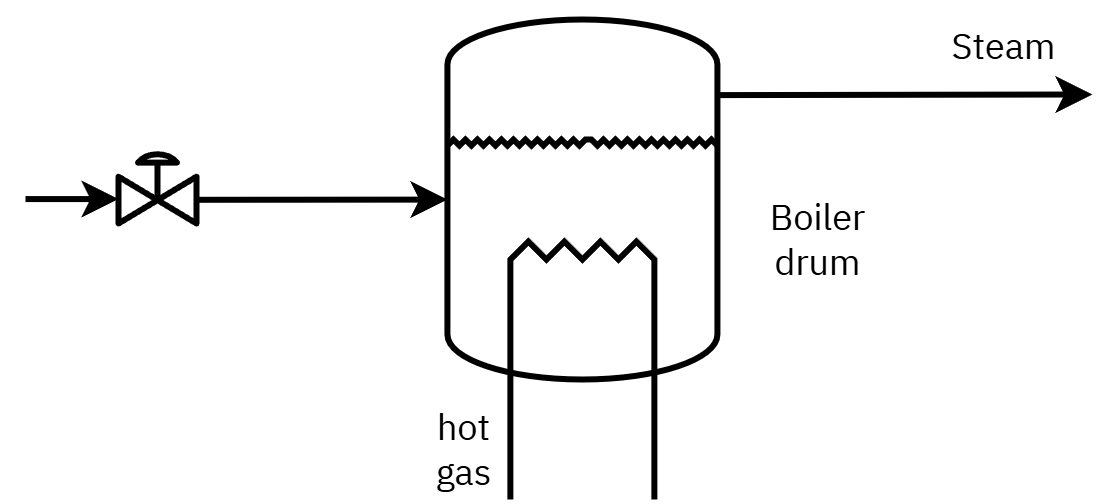

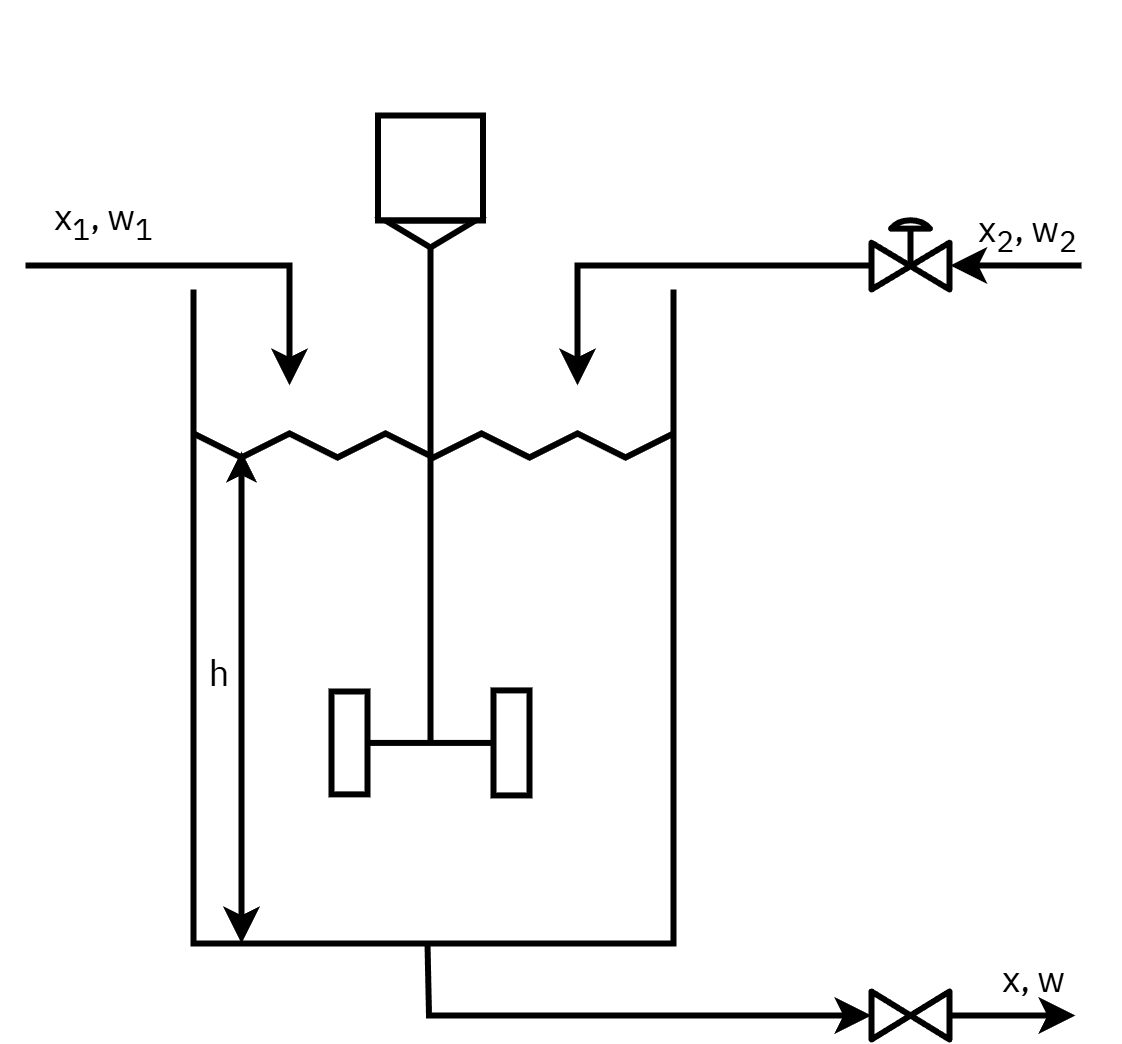

- Consider a boiler drum as shown in the figure below

Identify controlled variable, manipulated variable and disturbance

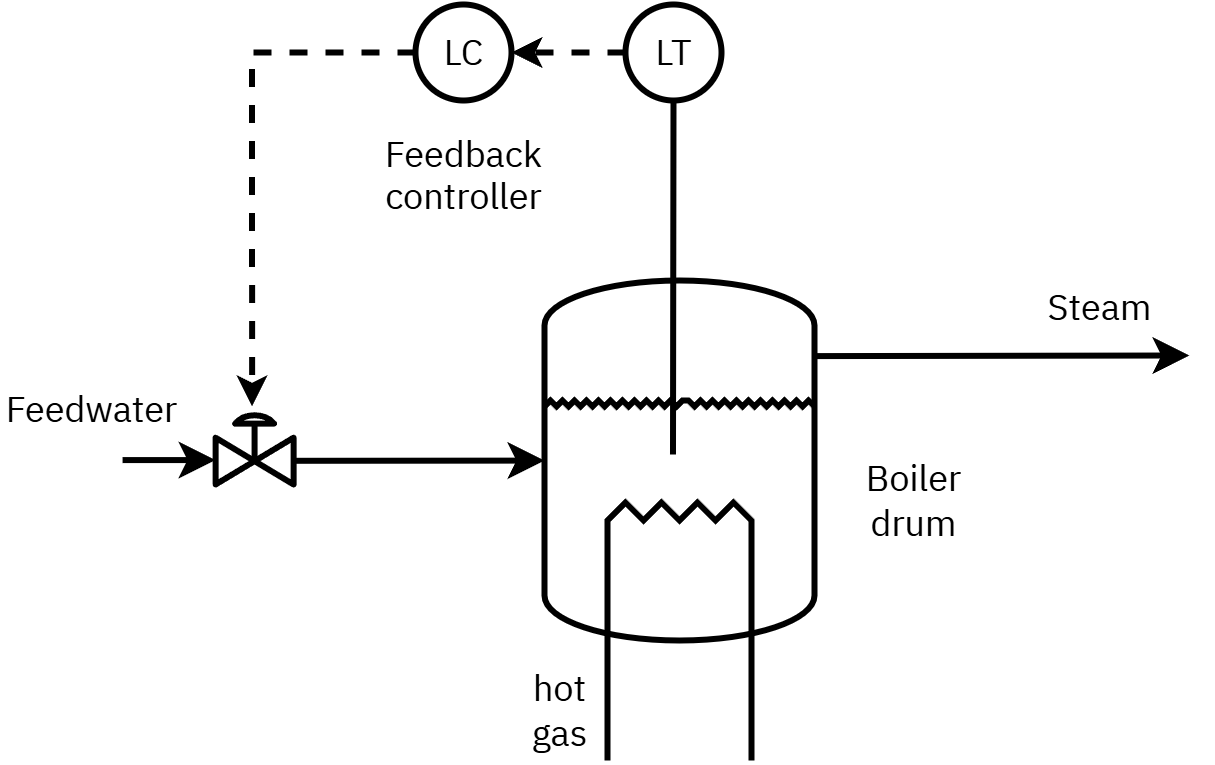

Draw a conventional feedback control to maintain liquid level in the boiler.

What are the drawbacks of this system?

Controlled variable: Boiler drum liquid level.

Manipulated variable: Feedwater flow, via the feedwater control valve or pump speed.

Major disturbances: Steam demand, furnace heat input, drum pressure changes, feedwater pressure or temperature changes, and blowdown flow.

Drawbacks of this simple system:

Poor rejection of steam flow disturbances. A sudden increase in steam demand lowers level before the controller reacts.

Shrink and swell effects. Pressure and boiling changes cause apparent level changes that mislead the controller.

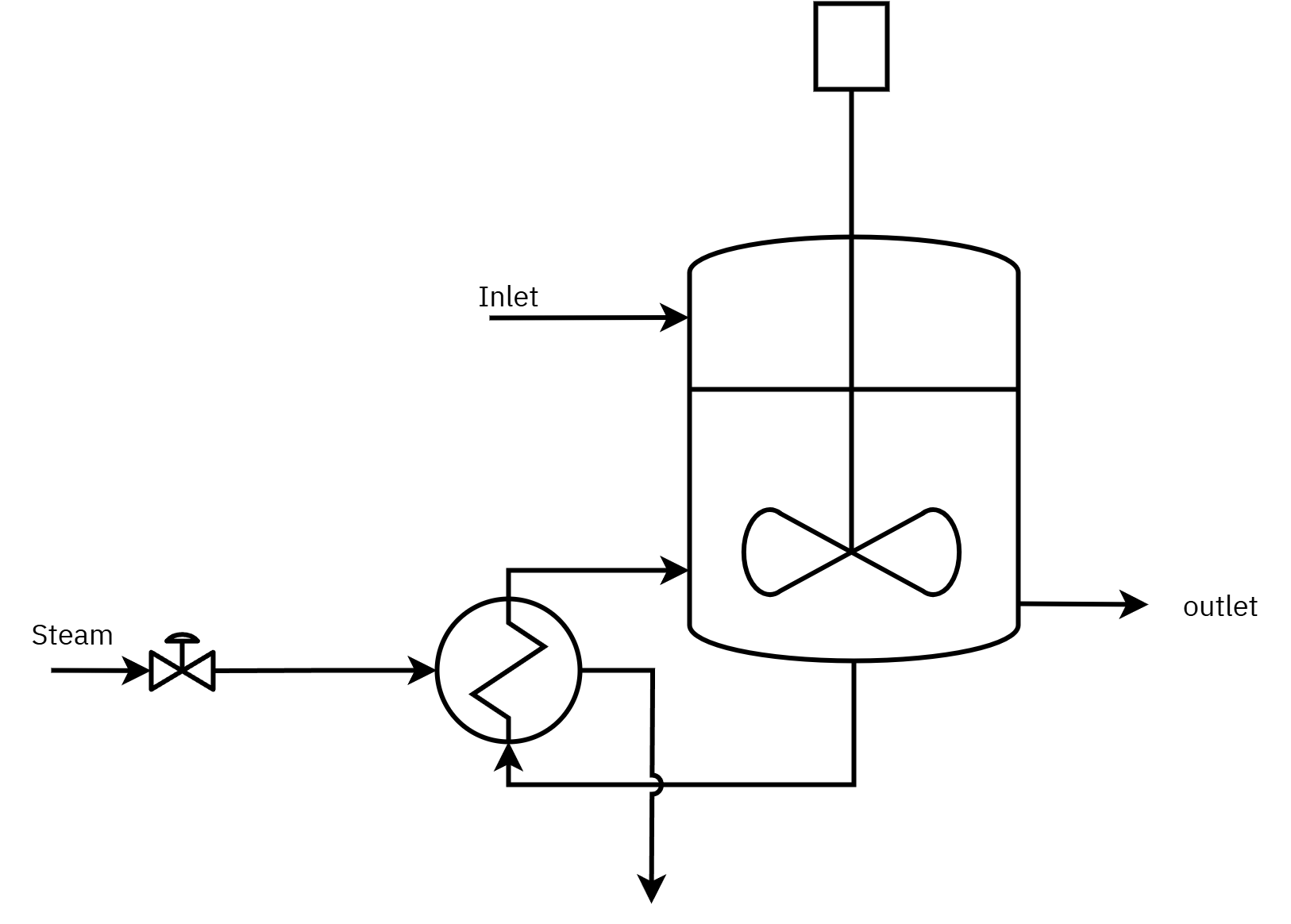

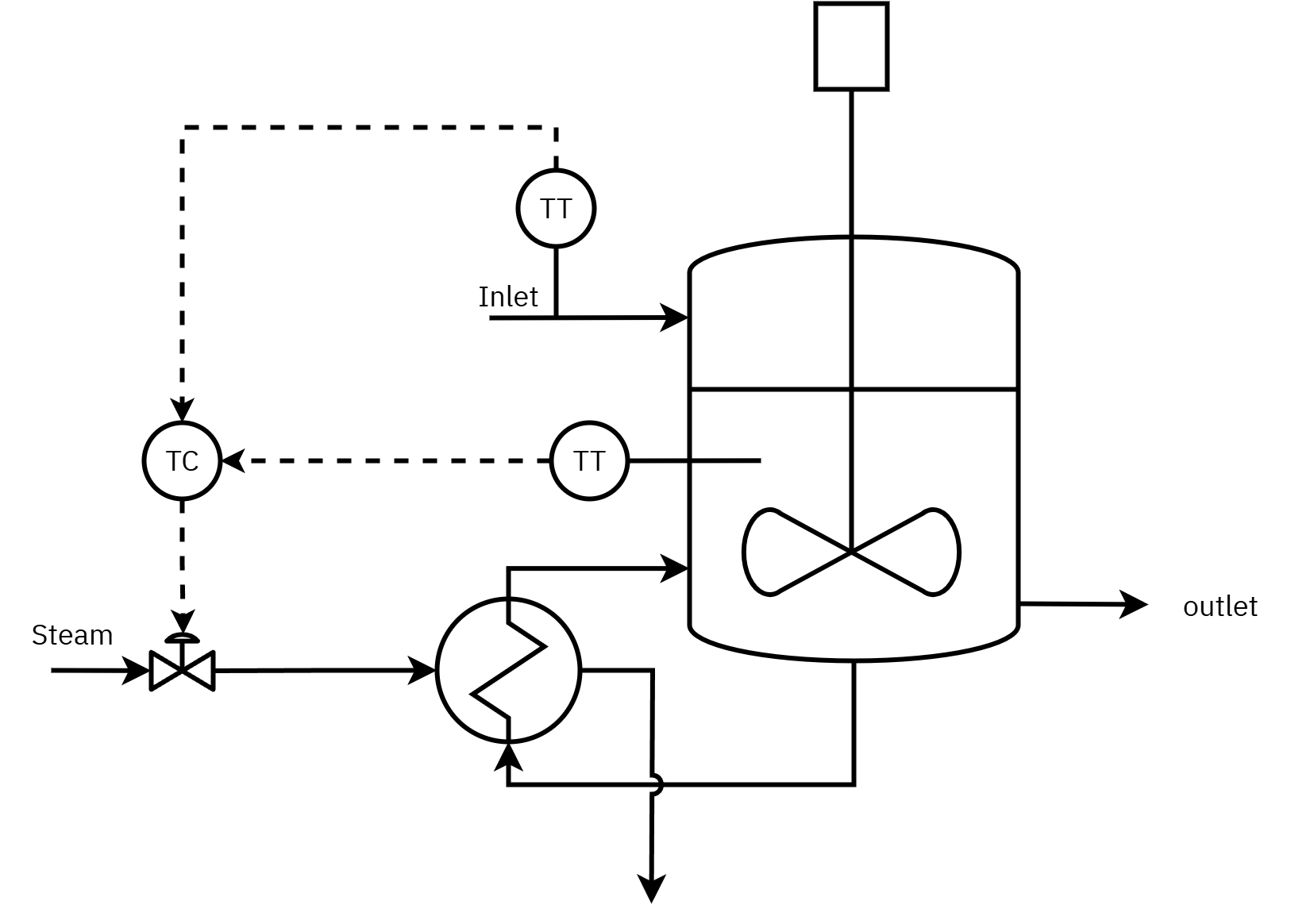

- Consider the operation of heat exchanger to demonstrate the application of feedforward control strategy. Identify all disturbances and the target disturbance to be remove using the feedforward control strategy

Objective: keep outlet temperature at setpoint by manipulating steam flow.

Controlled variable: Outlet temperature,

Manipulated variable: Steam flow to the exchanger.

Important disturbances:

- Feed (inlet) flow rate,

- Feed (inlet) temperature,

- Product draw‑off flow changes (level control actions).

- Steam supply pressure/temperature to the valve.

- Exchanger fouling or changes in overall

- Condensate backpressure or trap performance.

- Pump/recirculation rate variations.

- Ambient heat losses and property changes (

Target disturbance for feedforward:

- The dominant, measurable load changes: inlet flow

- For the blending system shown in Figure 5

Identify controlled variable

Manipulated variable

Disturbance

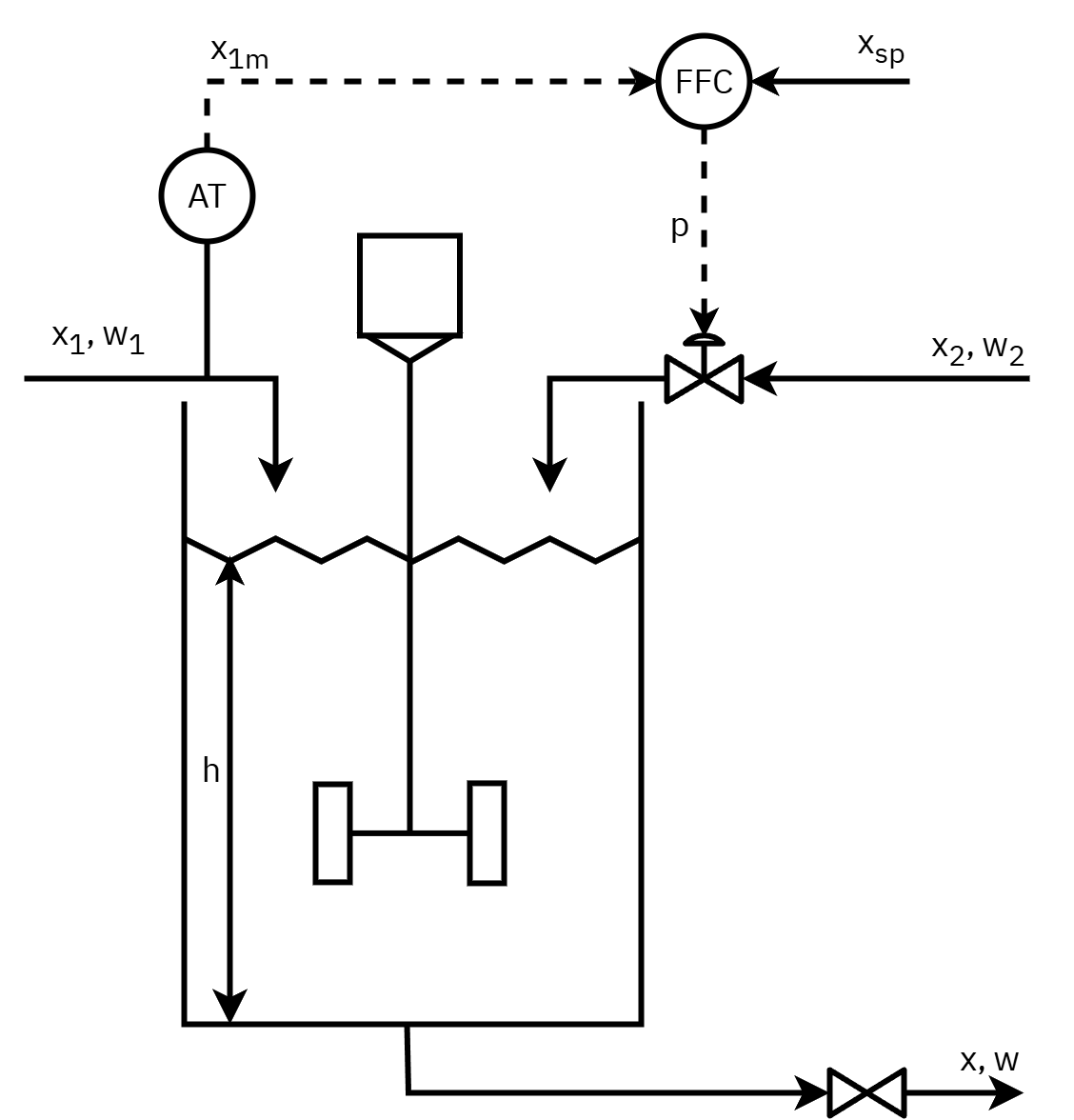

Propose a feedforward strategy to control outlet composition

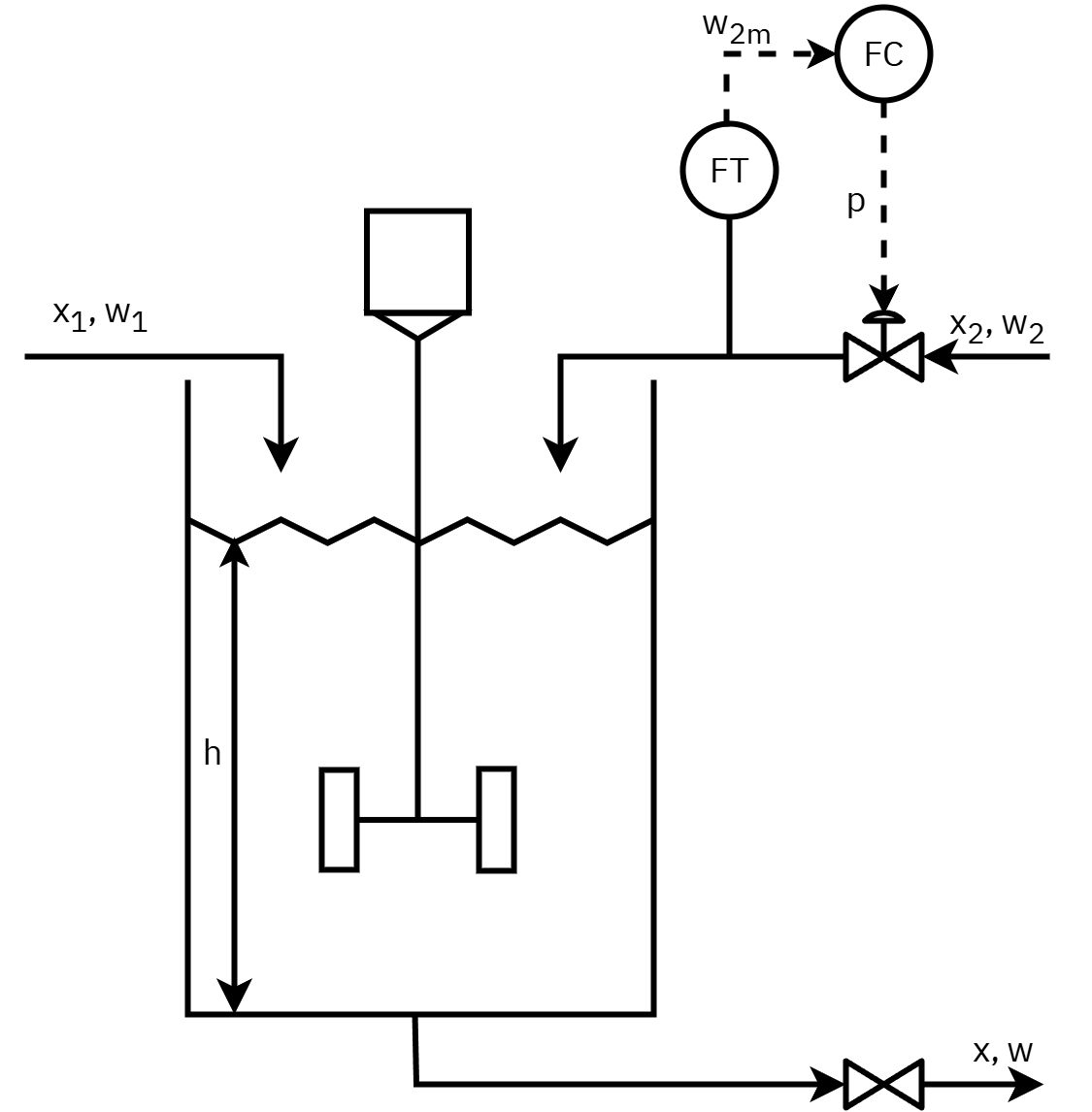

Propose a strategy to control composition when inlet flowrate

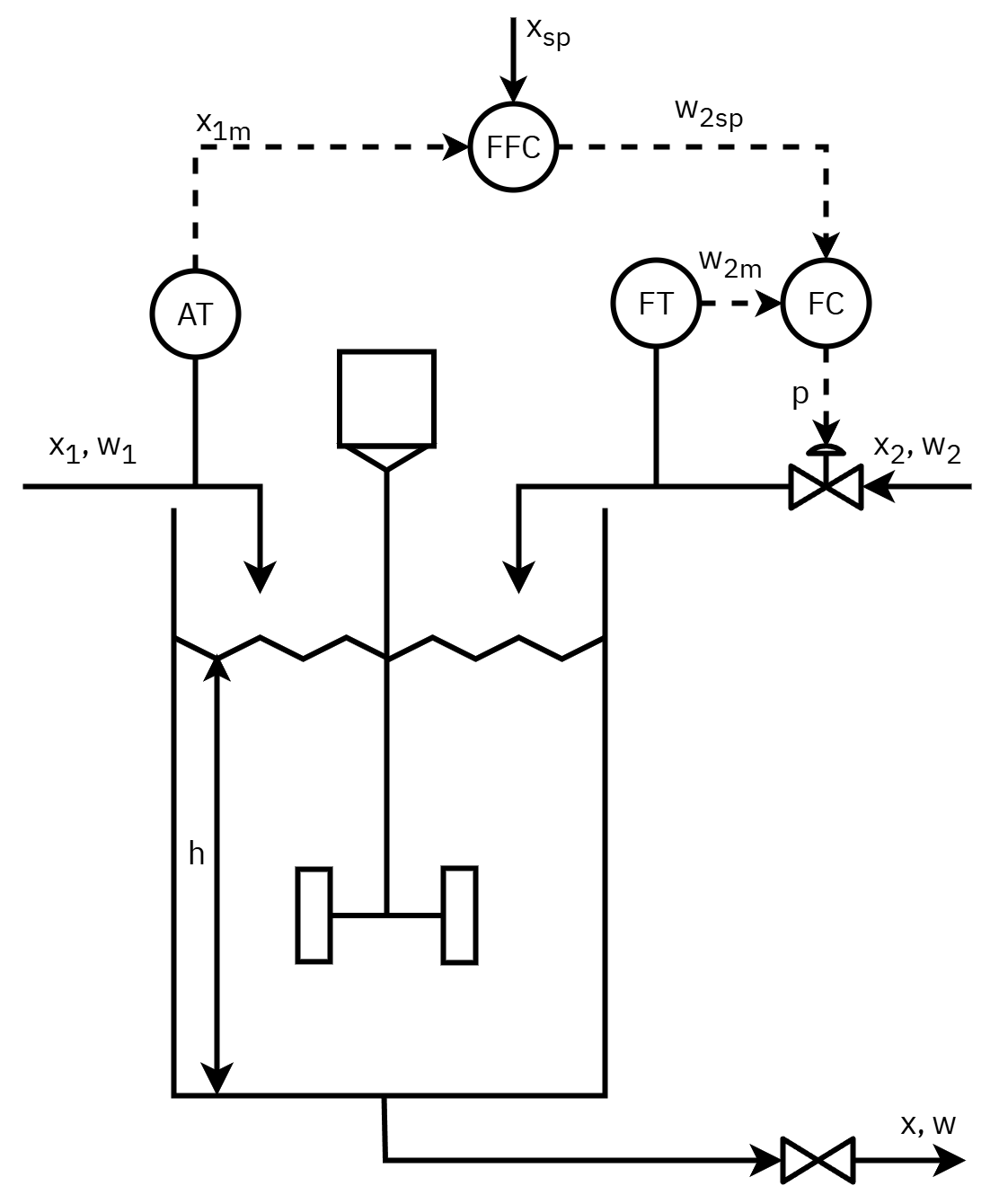

propose a feedforward feedback control strategy

- Identify controlled variable

- Outlet composition x

- Manipulated variable

- the flow of stream 2, w2

- Disturbance

- Stream‑1 flow and composition, w1 and x1

- Stream‑2 composition x2 (and sometimes w2 if it is not the MV)

- Density or temperature changes that affect analyzer or flowmeters

- Propose a feedforward strategy to control outlet composition

- Propose a strategy to control composition when inlet flowrate

- propose a feedforward feedback control strategy

The process, and disturbance transfer functions for problem 1 are given by

use PID tuner app to tune a PID controller for this process.

Propose a feedforward control system for Figure 1. Explain how a feedforward control can improve disturbance rejection or regulatory control performance.

Calculate ideal feedforward compensator for problem 1 and implement pure feedforward control scheme in simulink.

Draw a combined feedforward-feedback PID for Figure 1. Implement feedforward-feedback system in simulink.

Consider the following process and disturbance transfer functions:

Do the following:

For the process given above, can an idealized feedforward controller be used to reject the disturbance.

Obtain a feedforward controller and PID controller for the process above using the unified feedforward-feedback control method.

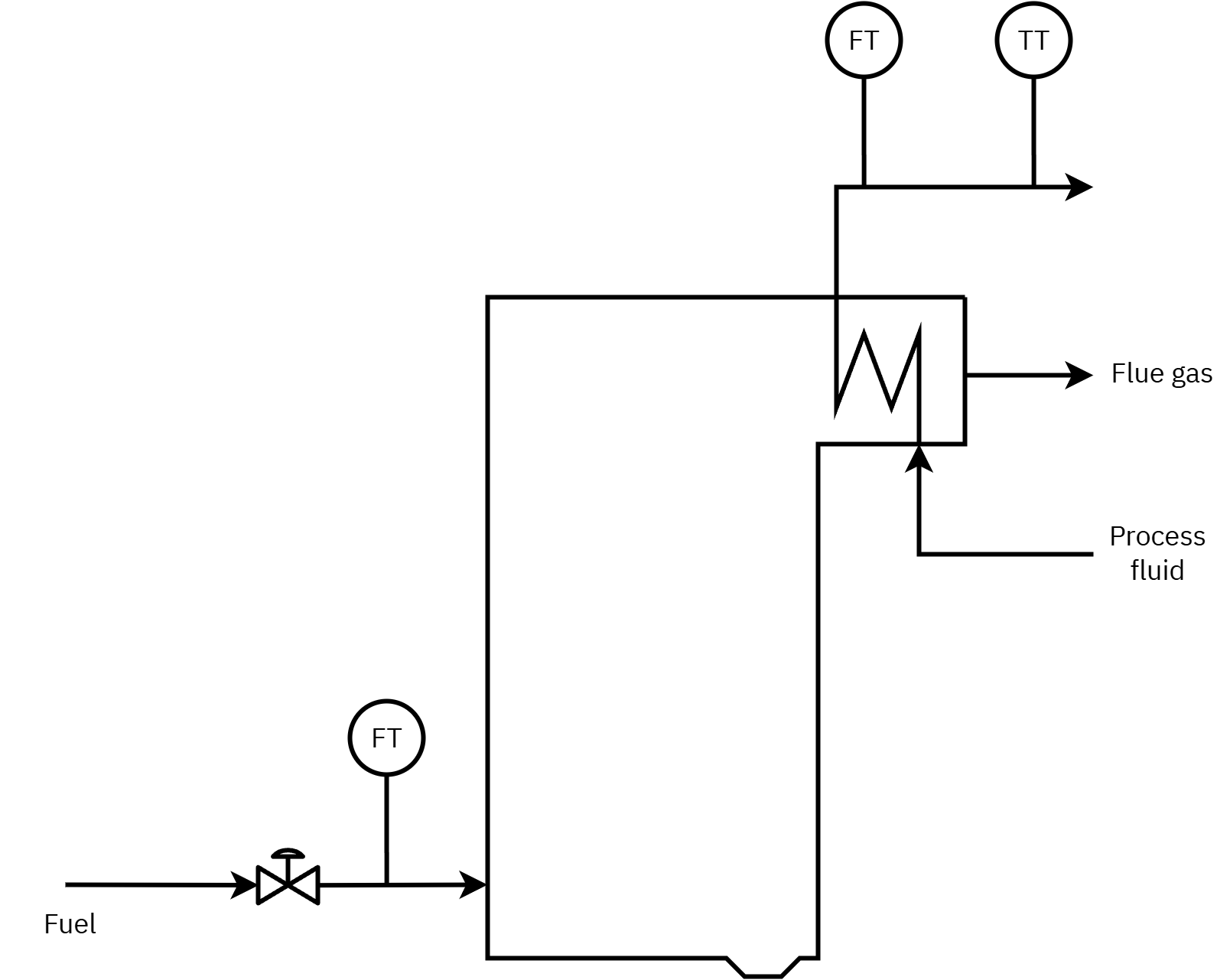

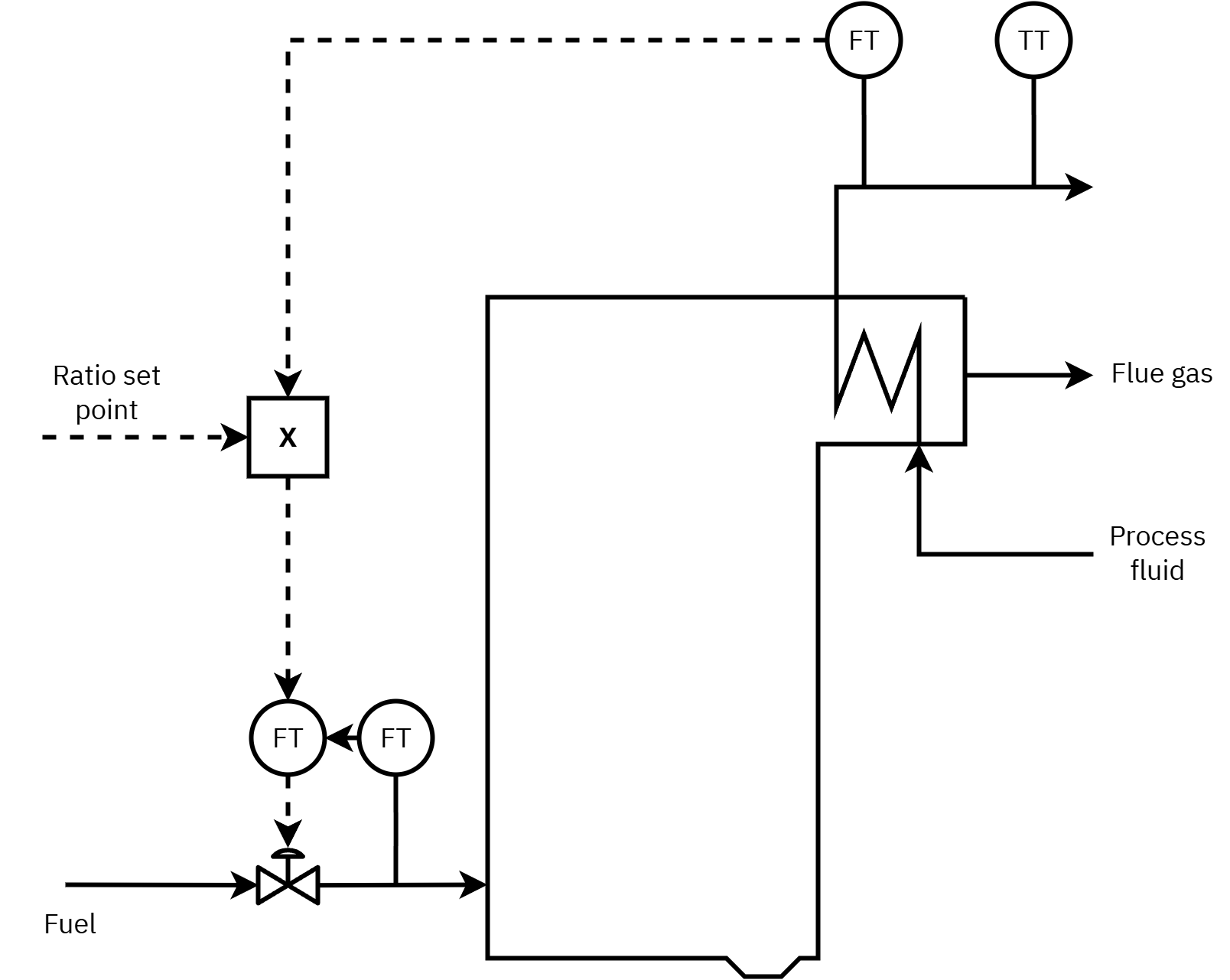

Furnace ratio control Figure 9

Draw the schematic of a ratio control strategy. What is the target disturbance? What is the manipulated variable? What is the controlled variable?

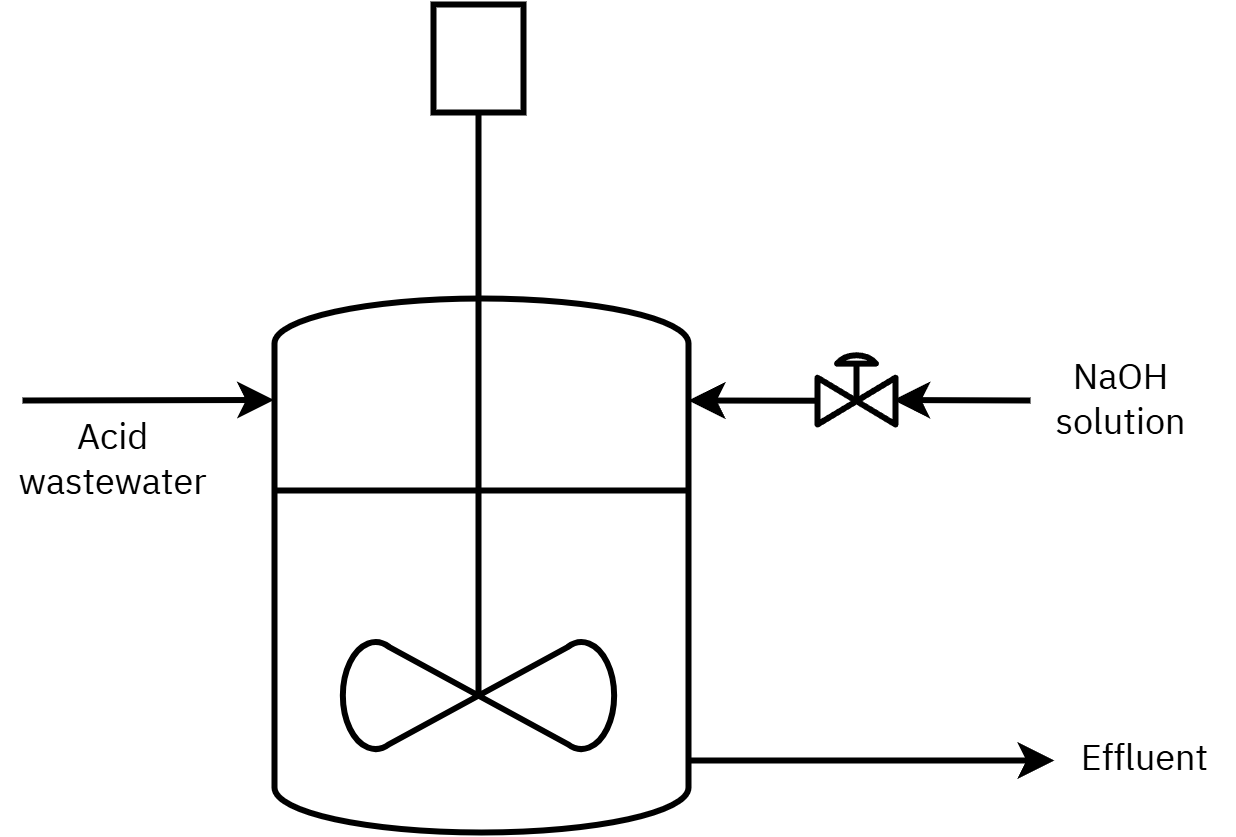

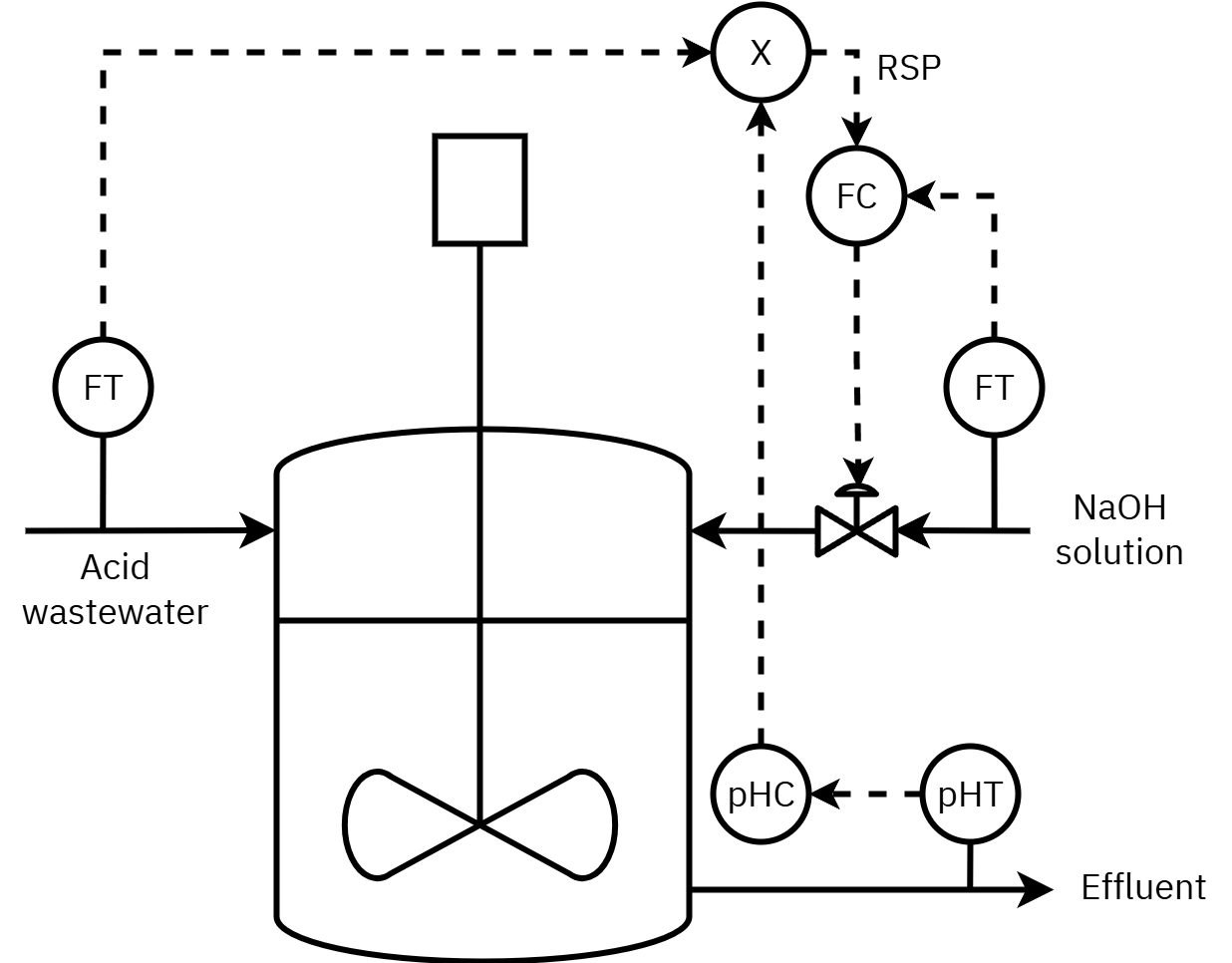

Wastewater pH neutralization Figure 11

Devise a ratio control strategy to provide desired flow rate of NaOH solution to maintain the pH of the effluent.

Citation

@online{utikar2023,

author = {Utikar, Ranjeet},

title = {Feedforward and Ratio Control},

date = {2023-07-30},

url = {https://amc.smilelab.dev/content/notes/02-ratio_and_feedforward_control/in-class-activities.html},

langid = {en}

}