Objectives

- To demonstrate the application of a Low Select (LS) override control strategy for protecting a heat exchanger tube from overheating due to excessive heating.

- To develop a MATLAB Simulink model for the LS control strategy and evaluate its performance under different process variations.

Process Information

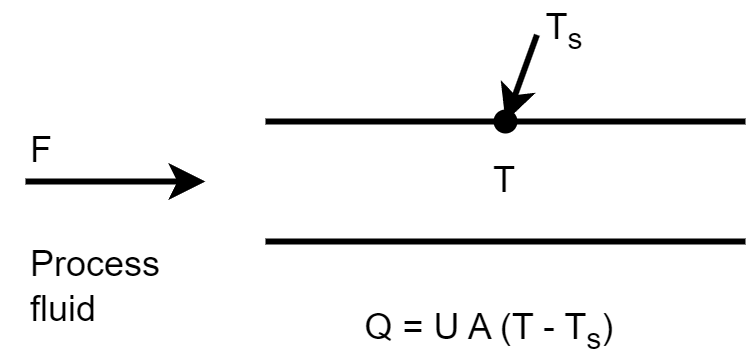

A process fluid is heated using steam in a heat exchanger.

If the process fluid flow rate suddenly increases, there will be a large drop in the process fluid temperature

However, if

Process fluid temperature transfer function

Heat exchanger tube temperature transfer function

At steady-state:

- Process fluid temperature = 300°C

- Tube skin temperature = 350°C

- Maximum allowable tube skin temperature = 400°C

Methodology

- Model Development

- Create a MATLAB Simulink model for the LS control strategy.

- Implement two controllers:

- Process fluid temperature controller

- Tube skin temperature controller

- The LS block selects the lower output to prevent overheating.

- Create a MATLAB Simulink model for the LS control strategy.

- Simulation Cases

- Nominal operation: Observe the system response to setpoint changes in process fluid temperature.

- High steam flow rate: Simulate a rapid increase in steam flow rate causing potential overheating.

- Process gain variation: Change the process gain of

- Process time constant variation: Change the time constant of

Report Format

Your report (5 pages maximum) should include the following:

- Submission Details

Include a brief table at the beginning of the report with the following information:

| Lab Title: | Lab 03 - Override Control | Student Name | ID |

| Unit: | CHEN4011 | Student 1 | 12345678 |

| Date: | 12 August 2025 | Student 2 | 87654321 |

Objective & Problem Statement

Briefly describe the LS control strategy and its purpose in preventing heat exchanger damage.

Methodology & Implementation

- Provide a Simulink diagram of the LS control strategy.

- Explain the roles of both temperature controllers.

- Describe how the LS block operates in the model.

Results

- Show the system responses for:

- Setpoint tracking

- Tube skin temperature protection under excessive heating

- Include well-labeled plots for:

- Nominal operation

- High steam flow rate disturbance

- Process gain ±10% for

- Process time constant ±10% for

- Summarize relevant performance metrics (IAE, overshoot, settling time).

- Show the system responses for:

Analysis and Discussion

Address the following:

- Under what conditions does the LS controller select the tube skin temperature controller’s output?

- How does a ±10% change in the gain of

- How does a ±10% change in the time constant of

- Quantitatively compare performance metrics between nominal and altered conditions.

Conclusion

- Summarize your findings on LS override control effectiveness.

- Discuss practical applications in industrial safety control.

Assessment Rubric (20 Marks Total)

| No | Section | Marks | Evaluation basis |

|---|---|---|---|

| 1. | Objectives & Problem | 2 | Clarity of problem definition; articulation of objectives |

| 2. | Methodology and Implementation | 4 | Correctness and clarity of Simulink model; explanation of LS control strategy |

| 3. | Results | 4 | Quality, relevance, and labeling of plots; completeness of performance data |

| 4. | Analysis and Discussion | 6 | Insightful interpretation; robustness; impact of process variations |

| 5. | Conclusion and Presentation | 4 | Coherent summary; quality of writing, formatting, and visual presentation |

Citation

@online{utikar2023,

author = {Utikar, Ranjeet},

title = {Lab 03: {Override} {Control}},

date = {2023-08-13},

url = {https://amc.smilelab.dev/content/labs/lab-03/},

langid = {en}

}