Multivariable Centralized Control and MPC

Advanced Modeling and Control

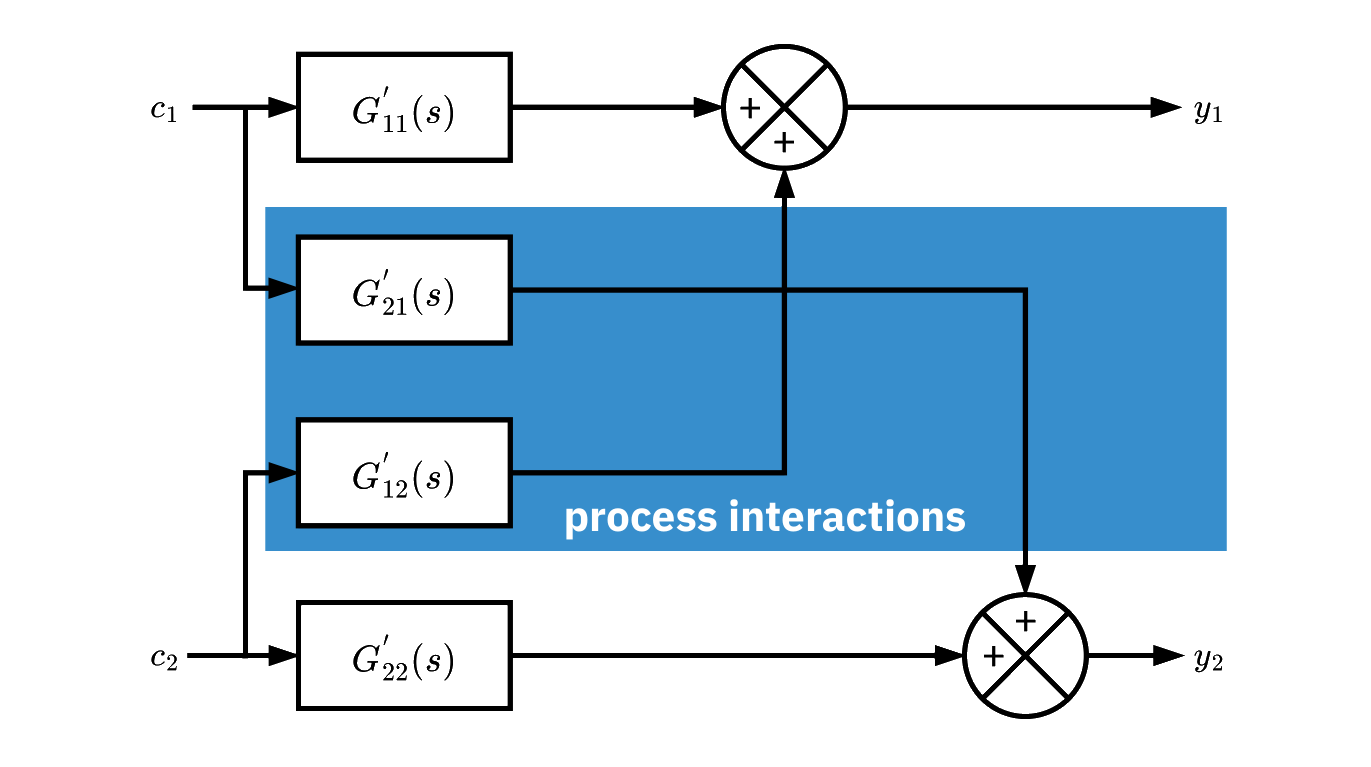

2x2 MIMO process system

- Inputs: c1,c2. Outputs: y1,y2.

- Plant ransfer function matrix

G=[G11′G21′G12′G22′] - G12′ is the transfer from c2 to y1.

- Interactions: a change in c1 or c2 affects both outputs.

- Cross terms G12′ and G21′ create loop coupling.

- Interactions can limit decentralized control performance.

- Decoupler can be used to reduce the coupling effect

- Model predictive control (MPC)

Decoupling controller

A decoupling controller (decoupler) can be added to decentralized control

to reduce process interactionsTypes of decoupling systems:

Partial decoupling (one-way):

Cancels the interaction in one direction

Most common in practice

Complete decoupling (two-way):

Cancels interactions in both directions

Useful for severe interactions but often requires very high control action

Leads to increased valve wear and tear

A one-way decoupler is typically designed for a pair of control loops to

cancel the interaction from one loop to the otherTwo decouplers can be used for the same pair of loops to cancel interactions

in both directions

One way decoupler

- Assume perfect cancellation of coupling effect from loop 2 to loop 1

U2D12G11+U2G12=0

∴D12=−G11G12

- General equation for decoupler Dij

Dij=−GiiGij

- Dij is used to remove the coupling effect from loop j to loop i

Two way decoupler

For an n×n MIMO system, n(n−1) decouplers are required in a complete decoupling system

Complete decoupling is often not practical for large MIMO systems

Partial decoupling is more commonly adopted

Multi-loop controllers for distillation column

- A common application of multi-loop control is the control of a distillation column

- There are 4 controlled variables:

- Liquid level in reflux drum

- Liquid level at the bottom of the column

- Top composition

- Bottom composition

- Liquid level in reflux drum

- This forms a 4×4 decentralized control system

- Each loop employs an individual PID-type controller

Multivariable control (MPC)

For weak interactions and loose constraints, a simpler multi-loop PID

approach is often sufficientFast, lightly coupled units can run well with well-tuned SISO loops

In MIMO systems with strong interactions, multi-loop coordination becomes complexMultivariable Predictive Control (MPC)

- Uses a process model to predict future behavior and choose control moves

over a short horizon - The controller optimizes, applies the first move, then repeats at the next

sample

- Uses a process model to predict future behavior and choose control moves

Compared with multi-loop PID, MPC considers all inputs and outputs together

and accounts for interactionsMPC enforces constraints on actuators and process variables explicitly

MPC looks ahead in time rather than reacting loop by loop

Advantages

- Better coordination when loops are strongly coupled

- Safer, more efficient operation under tight constraints

- Improved performance on processes with delays and slow dynamics

- Better coordination when loops are strongly coupled

Multivariable controllers for distillation column

- Replace the two SISO composition controllers with a single multivariable controller (MPC)

- MPC reduces the negative effects of loop couplings between top and bottom compositions

- Loop couplings are a major limitation to achievable control performance

- Mixed control strategy:

- MPC for composition loops

- PID controllers for level loops

- Keep level controllers as SISO since interactions between level loops are relatively small

Multi-loop control block diagram

Multivariable controller block diagram

Model Predictive Control (MPC)

Overview

- Widely used multivariable control approach in process industry

- often considered the gold standard for coordinating interacting loops

- Handles soft and hard constraints on inputs and outputs

- Conventional PID cannot enforce constraints explicitly

- Can operate close to economic or safety limits without violating constraints

- Several industrial variants exist; dynamic matrix control (DMC) is the most common lineage

Advantages

- Provides decoupling to reduce effects of process interactions

- Enables feedforward compensation for measured disturbances

- Can address process nonlinearity when a nonlinear model is used

- Enforces constraints directly on variables and move rates

Genealogy of linear MPC algorithms

MPC emerged in the late 1970s and early 1980s, evolving from Linear Quadratic Gaussian (LQG) control introduced by Kalman in the 1960s

MPC performs prediction within a finite time horizon, unlike LQG which assumes infinite horizon and unconstrained optimization

- 1st generation (1970s)

- DMC: dynamic matrix control Shell implementations

- IDCOM: Texas Instruments multivariable controller

- 2nd generation (1980s)

- QDMC: quadratic dmc shell

- SMOC: setpoint multivariable optimal control

- IDCOM-M: multivariable extension

- 3rd generation (1990s)

- DMCPLUS: AspenTech commercial successor

- RMPCT: Honeywell robust MPC

- SMOC-II: Shell evolution

- 4th generation (2000s and onward)

- DMC+ enhanced commercial variants

Dynamic Matrix Control (DMC)

- Developed by Shell Oil engineers and first applied in 1973

- Based on a linear step response model of the plant

- Uses a quadratic performance objective over a finite prediction horizon

- Computes future control actions so the controlled variables follow setpoints as closely as possible

- Became the first widely adopted form of model predictive control in the process industry

Discrete-Time Step Response Model (DTSRM)

- Dynamic Matrix Control (DMC) requires a dynamic model of the process

- DTSRM is the model structure used in DMC

- Provides the basis for calculating optimal control actions

- Equivalent to the transfer function model Gp used in conventional control

- Captures the effect of manipulated variables (MV) on controlled variables (CV)

- Offers the same process information as Gp but expressed in step response form

DTSRM developed from FOPDT

- Start with a FOPDT model

Gp(s)=u(s)y(s)=s+1exp(−s),Kp=1,τp=1,θp=1

- Apply a unit step change in input

Δu(s)=s1at t=t0

- Choose a fixed sampling time, e.g. Ts=1

- From the step test, derive DTSRM coefficients

ai=Δu(t0)y′(i),y′(i)=y(i)−y(0)(1)

- A set of coefficients ai for i=0,1,2,…,n defines the DTSRM

Example: DTSRM

| t | i | Δu | y(t) | aᵢ |

|---|---|---|---|---|

| 0 | 0 | 1 | 0.00 | 0.00 |

| 1 | 1 | 0 | 0.00 | 0.00 |

| 2 | 2 | 0 | 0.63 | 0.63 |

| 3 | 3 | 0 | 0.87 | 0.87 |

| 4 | 4 | 0 | 0.95 | 0.95 |

| 5 | 5 | 0 | 0.98 | 0.98 |

| 6 | 6 | 0 | 0.99 | 0.99 |

| 7 | 7 | 0 | 1.00 | 1.00 |

| 8 | 8 | 0 | 1.00 | 1.00 |

- Input step change at t=0 by 1 unit

- Only one input change is applied at t=0

- Several input changes could be applied at different t values

- A set of coefficients ai for i=0,1,…,8 is calculated

- n is chosen so that the process reaches a new steady state

Response of a process to an input change

- From Eqn. (1):

y(ti)=y′(ti)+y(t0)=aiΔu(t0)(2)

- Eqn. (2) can be extended to predict y(t) for several input changes at t=t0,t1,t2,…

⎩⎨⎧y1−y0=a1Δu0=a1Δu(t0)y2−y0=a2Δu0+a1Δu1y3−y0=a3Δu0+a2Δu1+a1Δu3(3)

- In general:

yn−y0=i=1∑naiΔu(tn−i)(4)

Response to input changes in matrix form

y′(t1)y′(t2)y′(t3)y′(t4)⋮y′(tn)=a1a2a3a4⋮am0a1a2a3⋮am−100a1a2⋮⋯000a1⋮a2⋯⋯⋯⋯⋱a1Δu(t0)Δu(t1)Δu(t2)Δu(t3)⋮Δu(tn−1)

y′=AΔu

- n is the prediction horizon

- m is the model horizon

- n>m, typically n=1.5m

- For a single input step change: Tstt=mTs

- For multiple input changes, settling time is longer than Tstt

Moving horizon algorithm

Moving horizon algorithm

Future manipulated variable (MV) values are chosen to regulate the controlled variable (CV) to its setpoint using the DTSRM and past input history

After each control interval, the present CV value and the last MV change Δu(t) are measured

The controller recalculates a new sequence of MV values into the future to meet the control objective

Only the first move from the optimized sequence is implemented

- At the next interval, the horizon shifts forward and the optimization is repeated

Prediction vector yP

- So far, we assumed that y(t0) is at steady state and MV changes occur only for t>t0

- In practice, this assumption is unrealistic since MV changes for t<t0 are likely to exist

- The effect of past input changes Δu(t) for t<t0 must be included to predict future CV behavior

- The prediction vector yP represents the effect of previous MV changes on CV for t>t0

- If no future MV changes are applied (Δu(t)=0 for t>t0), yP captures the continuing response of the CV

Prediction vector yP

- Assume the model horizon m time steps, so that an input change has reached steady state

- Using Eqn. (4), the prediction vector at t=t1 is

yP(t1)=y(t−m)+amΔu(t−m)+amΔu(t−m+1)+am−1Δu(t−m+2)+⋯+a2Δu(t−1)(5)

- Notes:

- a−m=am,a−m+1=am+1,…

- am+j=am for j=1,2,3,… once the steady state is reached

- Negative subscripts indicate sampling intervals before t0

- a−m=am,a−m+1=am+1,…

- General form:

yP(t1)=y−m+i=−m∑−1aiΔu(tm−i)

Matrix form of yP

yP(t1)yP(t2)⋮yP(tn)=y(t−m)y(t−m)⋮y(t−m)+APΔu(t−m)Δu(t−m+1)⋮Δu(t−1)

yP=y(t−m)+APΔuP

- n = prediction horizon (number of future steps, with n>m)

- m = model horizon (time steps needed for steady-state response)

- y(t−k) = value of CV at t=t0−kTs, where k is the number of steps from present to historical past

Prediction values of y(t) for t>t0

- Future CV values are predicted by combining effects of:

- Past input movements (prediction vector yP)

- Future input movements (Δu)

- Past input movements (prediction vector yP)

y~=yP+AΔu

∴y~=y(t−m)+APΔuP+AΔu

- Accuracy of predictions depends on:

- Errors in identifying DTSRM coefficients

- Unmeasured disturbances

- Nonlinear process behavior

- Lack of steady-state behavior at t=t−m

- Errors in identifying DTSRM coefficients

Reducing Effects of Process/Model Mismatch

Reliability of MPC requires that the deviation of the model from the actual process is small

- Large mismatch can degrade control performance

The error between measured y(t0) and predicted yP(t0) can be used to correct predictions

Recall equation (6):

y~=yP+AΔuPrediction error:

ε=yP(t0)−y(t0)Corrected model:

y=yP+AΔu+ϕTError vector:

ϕ=[ε,ε,ε,…,ε]Number of rows of ϕT matches the dimension of y

DMC Control Law

- DMC control law is based on minimizing the error from setpoint E

- The objective function Φ is the sum of the squared errors from setpoint over the prediction horizon n

Φ=i=1∑n[ysp−y(ti)]2

Error term: E(ti)=ysp−yP(ti)−ε

So, Φ=∑[E(ti)−yc(ti)]2

Taking derivative: ∂Δu∂Φ=AT(AΔu−E)=0

Hence the control law: Δu=KDMCE

where KDMC=(ATA)−1AT

DMC computations

Move Suppression Factor Q

Basic DMC can be very aggressive

- Focuses on minimizing deviation from setpoint

- Ignores large changes in MV levels

- Focuses on minimizing deviation from setpoint

This causes sharp changes in MV, which is undesirable

Solution: Add a move suppression term

- Introduce diagonal matrix Q2 into the control law

- Penalizes rapid MV adjustments

- Introduce diagonal matrix Q2 into the control law

Effect of q

- Larger q → more penalty on Δu

- Leads to smoother, less aggressive control actions

- Larger q → more penalty on Δu

Control law with suppression:

Δu=(ATA+Q2)−1ATE

Suppression matrix:

Q=q00⋮00q0⋮000q⋮0………⋱…000⋮q

Summary

Decouplers reduce control-loop interactions and improve performance

Two common industrial control architectures:

- Decentralized (multi-loop)

- Centralized (multivariable)

- Decentralized (multi-loop)

Model Predictive Control (MPC) is the most widely used multivariable controller in process industries

One of the most common MPC variants is Dynamic Matrix Control (DMC)

MPC requires a process model and an optimizer

Advantages of MPC

- Handles constraints explicitly

- Provides feedforward compensation for disturbances

- Manages process interactions effectively

- Can incorporate nonlinear models if needed

- Handles constraints explicitly

Optimal control actions are computed as

Δu=KDMCE

Advanced Modeling and Control