MIMO Systems: Decentralized control

Advanced Modeling and Control

Outline

- Multivariable process plants

- Methods of controlling process plant

- Decentralized Control vs. Centralized Control Systems

- Issues in decentralized control system

- Decentralized PID Control Design Methods

- Decoupling controllers

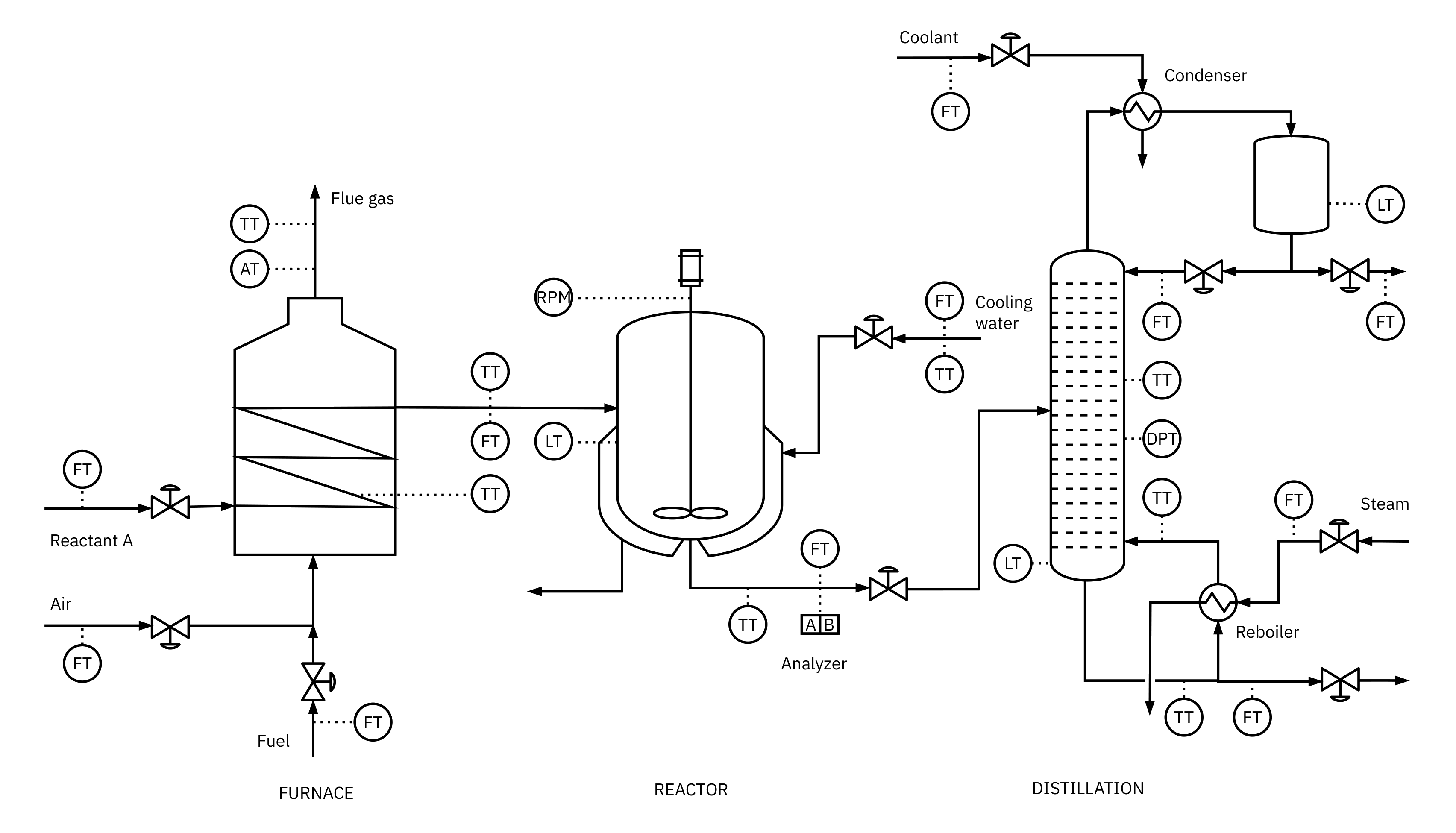

Real life processes

🤔 how many measurements are there?

- Real Process often have more than one input and one outputs.

- Real process has multi-input and multi-output (MIMO)

- Engineers attempt to select a set of controlled variables from a set of measurement.

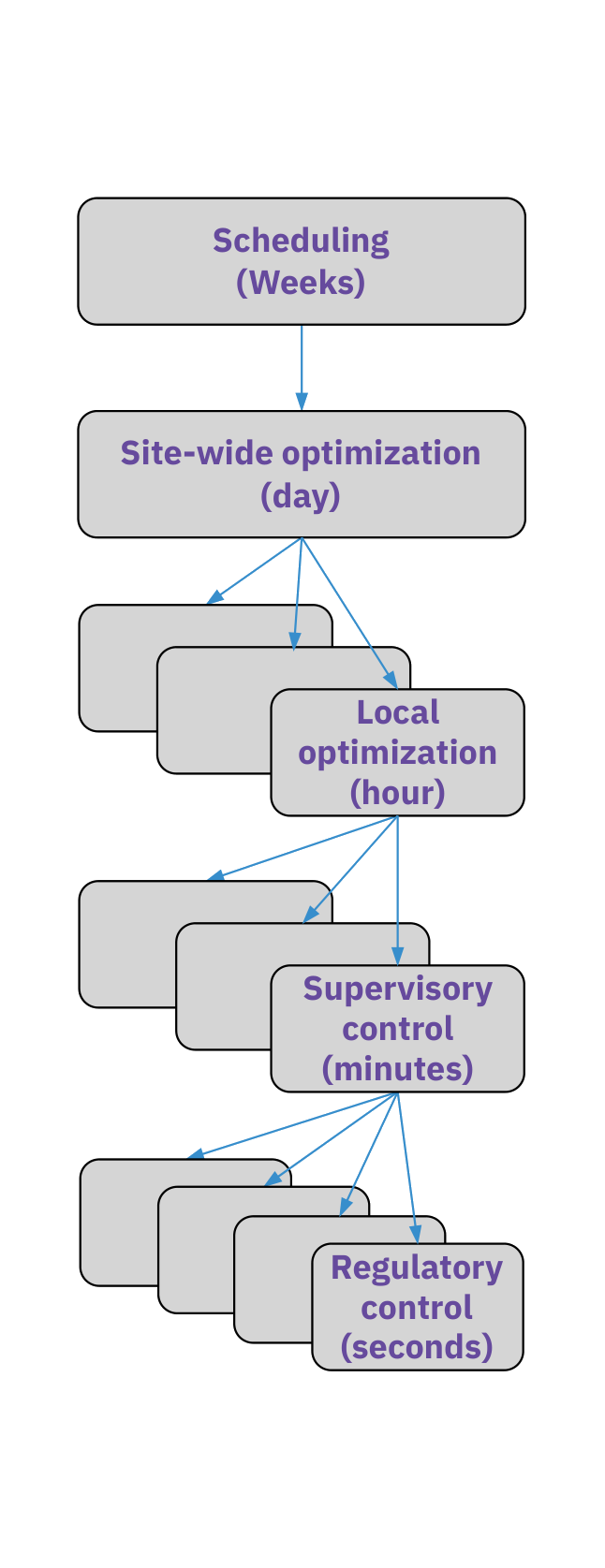

Plantwide control hierarchy

Several layers: regulatory, supervisory, optimization, scheduling.

Regulatory: multi-loop PID controls levels, temperature, flow, pressure. Ensures stability.

Supervisory: sends setpoints to the regulatory layer. May be centralized.

Optimization: real-time monitoring and optimization provide optimal targets for supervision.

Trade-off: plantwide optimization acts slower than local control.

Scheduling: inventory and production planning, often offline.

Use fast regulatory PID loops for stability, and let slower supervisory and optimization layers set plantwide targets and schedules.

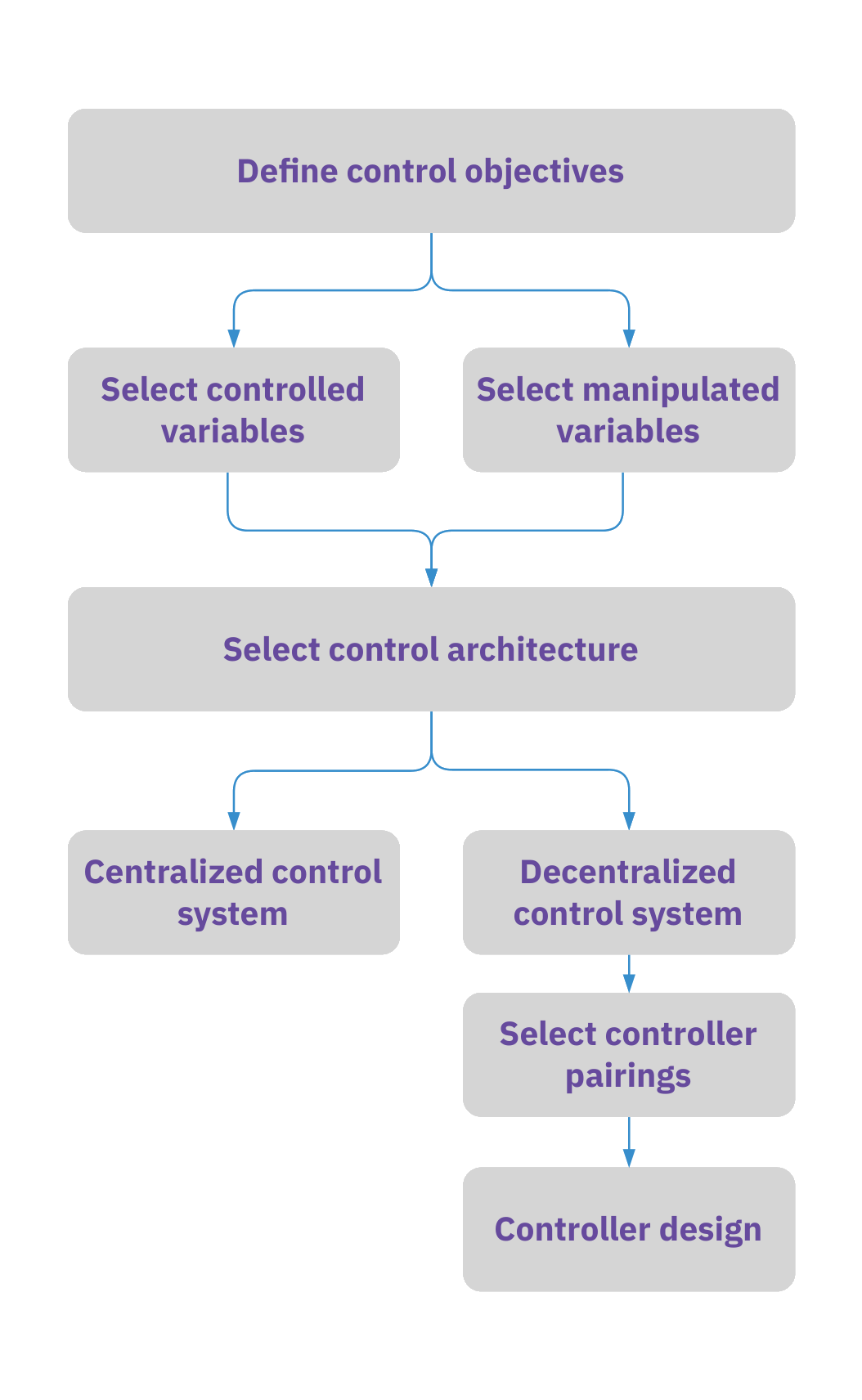

Plantwide control design flowchart

Define control objectives: explicit outcomes and implicit plantwide goals.

Select controlled and manipulated variables that support the explicit objectives and fit the plantwide philosophy.

- directly related to Explicit Control Objectives

- indirectly related to Implicit Control Objectives

Choose the control architecture: centralized or decentralized.

For decentralized (multi-loop PID) systems, decide controller pairings first to manage interactions, then design the controllers.

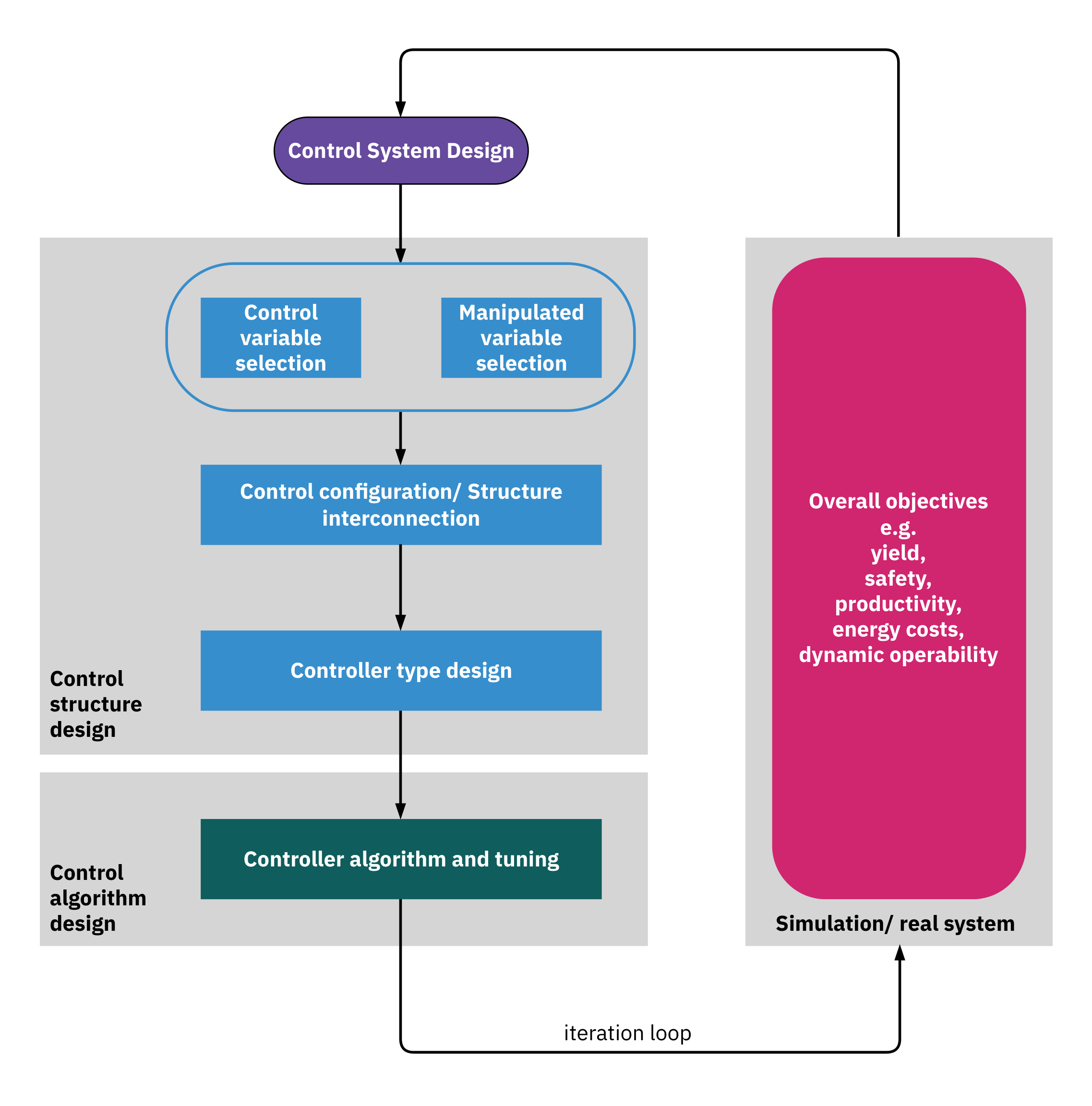

Plantwide control design tasks

Plantwide control design is iterative

Choose initial controller pairings.

note: different pairings may require redesign of individual controllers.

Design and tune controllers.

Simulate and assess plantwide performance.

Use a full-plant simulation to evaluate the complete design.

If targets are not met, revise pairings and retune.

Repeat until objectives are satisfied.

Validate controller pairings with full-plant simulation; if KPIs fall short, revise pairings and retune until objectives are met.

Operating objectives

Purpose: Define, prioritize, and measure what “good operation” means for the unit or plant.

Priority order (use as override order)

- Safety and compliance

- Equipment protection and mechanical limits

- Product quality and on-spec rate

- Throughput and stability

- Cost and profit

Typical objectives

- Maintain smooth operations.

- Protect equipment.

- Maximize yield of the desired product.

- Ensure safe operation.

- Minimize operating cost.

- Meet production specifications.

- Maximize profit subject to the constraints above.

Examples of control objectives

| Objective | Indicator variable (unit) | Typical limit or target | Primary MV(s) | Control notes |

|---|---|---|---|---|

| Avoid flooding/weeping in column | Tray dP, % flood [Constraint] | dP < limit, flood < 80% | Reflux, reboiler duty, feed rate | Add dP override selectors on reflux and duty. |

| Protect pump (no cavitation) | NPSH margin (m) [Constraint] | Margin > required | Suction drum level, recycle valve | Use minimum flow recycle and tight level control. |

| Keep reactor safe | Treactor (°C) [CV] | < Tmax, HH trip at Ttrip | Coolant flow, jacket duty | Cascade temperature to coolant valve, HH trip independent of PID. |

| Minimize utilities | Steam per ton, kWh per ton [Economic] | ↓ vs baseline | Reboiler duty setpoint, compressor load | Supervisor trims setpoints, bounded by quality and safety. |

| Achieve throughput | Feed rate (t/h) [Throughput] | ≥ plan | Feed valve, upstream schedule | Throughput held unless any constraint controller intervenes. |

Examples of control objectives

| Objective | Indicator variable (unit) | Typical limit or target | Primary MV(s) | Control notes |

|---|---|---|---|---|

| Avoid flooding/weeping in column | Tray dP, % flood [Constraint] | dP < limit, flood < 80% | Reflux, reboiler duty, feed rate | Add dP override selectors on reflux and duty. |

| Protect pump (no cavitation) | NPSH margin (m) [Constraint] | Margin > required | Suction drum level, recycle valve | Use minimum flow recycle and tight level control. |

| Keep reactor safe | Treactor (°C) [CV] | < Tmax, HH trip at Ttrip | Coolant flow, jacket duty | Cascade temperature to coolant valve, HH trip independent of PID. |

| Minimize utilities | Steam per ton, kWh per ton [Economic] | ↓ vs baseline | Reboiler duty setpoint, compressor load | Supervisor trims setpoints, bounded by quality and safety. |

| Achieve throughput | Feed rate (t/h) [Throughput] | ≥ plan | Feed valve, upstream schedule | Throughput held unless any constraint controller intervenes. |

Mapping objectives to CVs and MVs

Pick CVs and MVs that directly support each objective.

Put constraint controllers in place first (safety, equipment limits, environmental).

Add quality and inventory loops next, then throughput, then cost optimization.

Use override selectors so higher-priority loops take control when limits approach.

Provide simulation or digital twin checks for KPI impact before moving setpoints.

Document alarms and trips (setpoint, alarm, trip) for each safety-critical KPI.

Control strategy must achieve the entire set of objectives

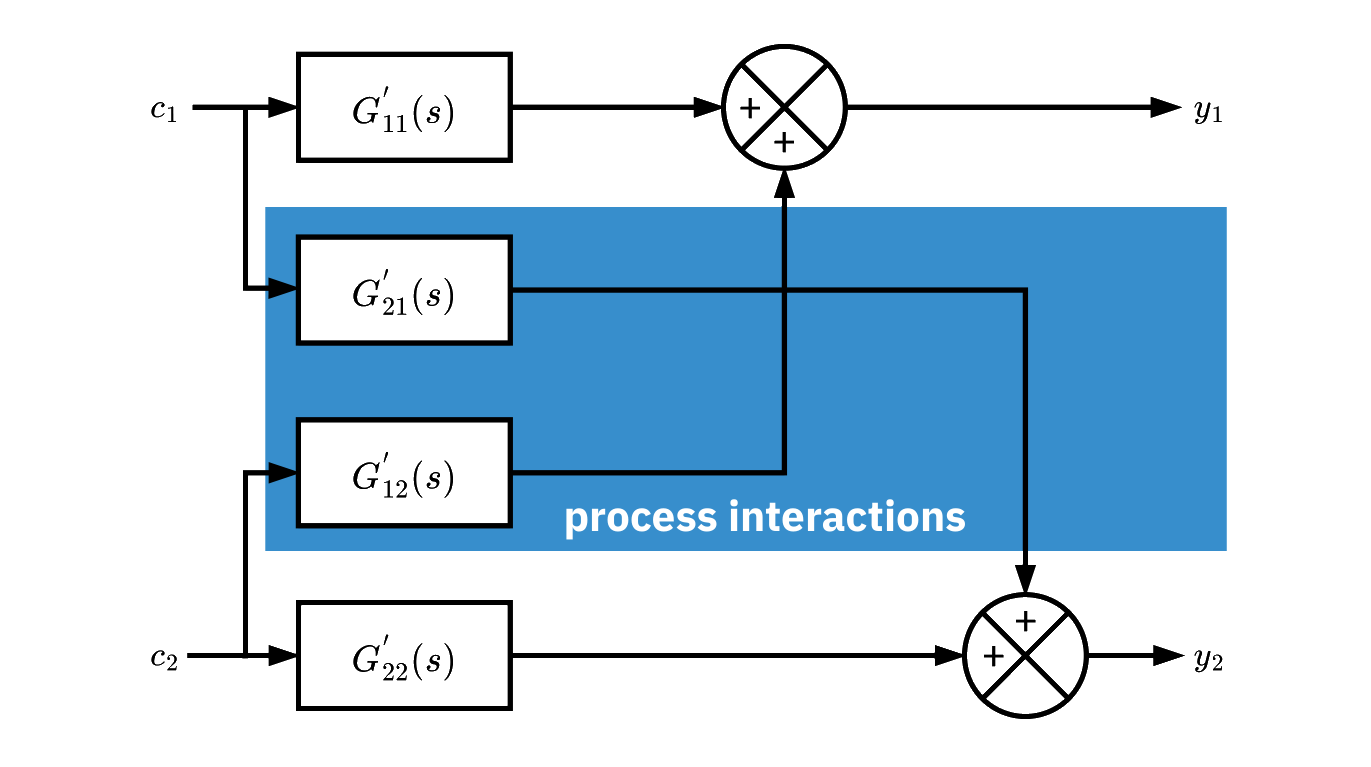

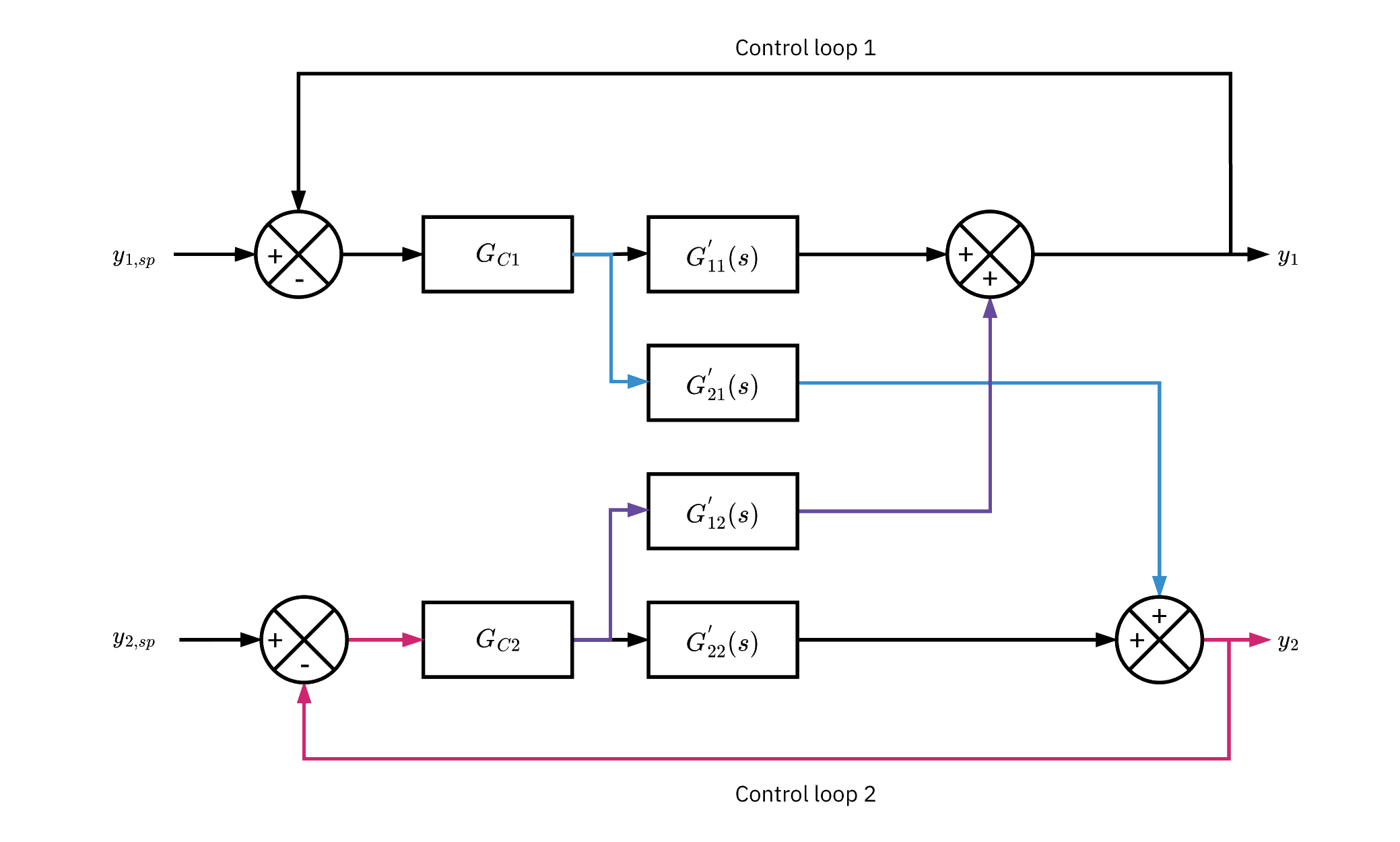

2x2 MIMO process system

- Inputs: c1,c2. Outputs: y1,y2.

- Plant ransfer function matrix

G=[G11′G21′G12′G22′] - G12′ is the transfer from c2 to y1.

- Interactions: a change in c1 or c2 affects both outputs.

- Cross terms G12′ and G21′ create loop coupling.

- Interactions can limit decentralized control performance.

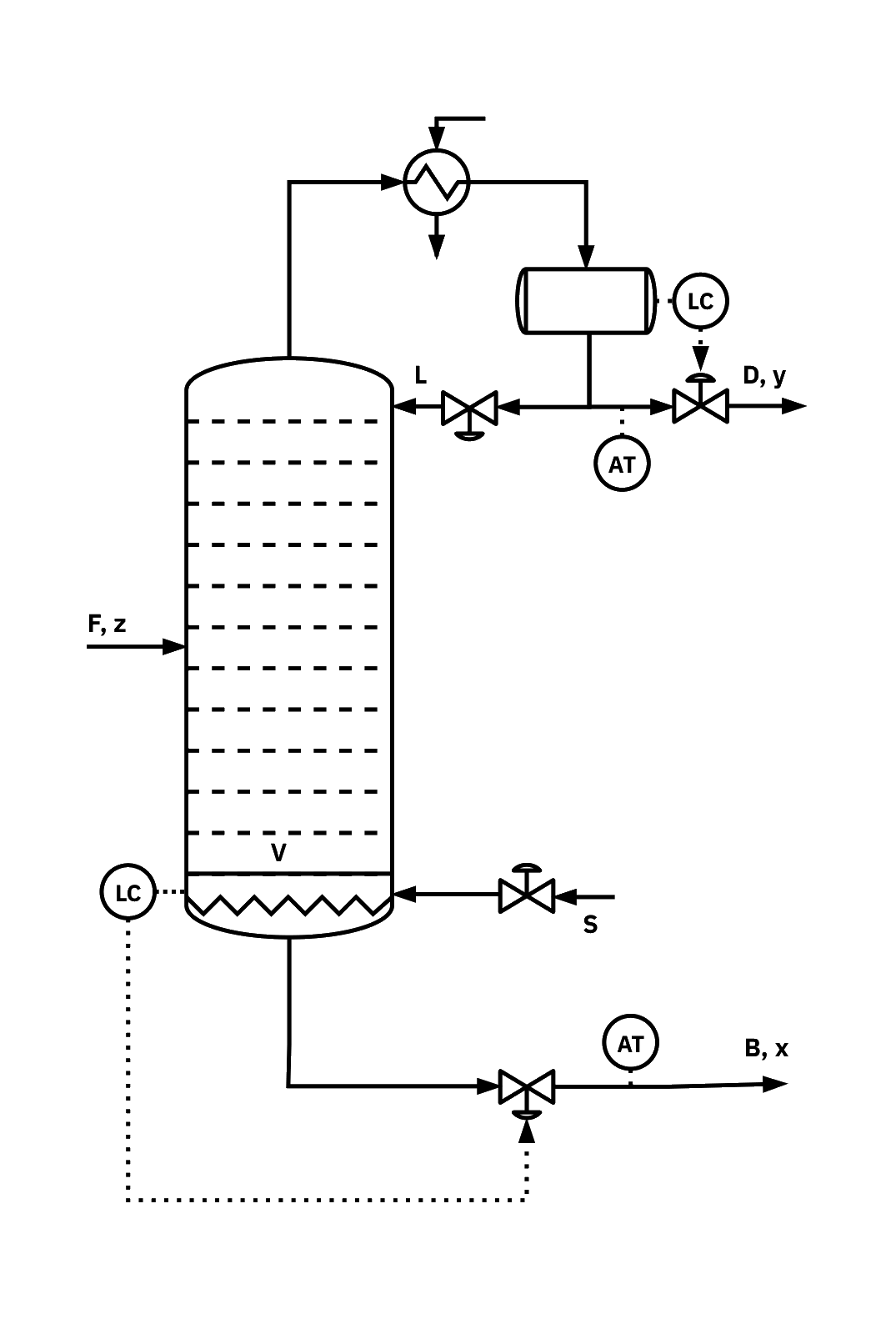

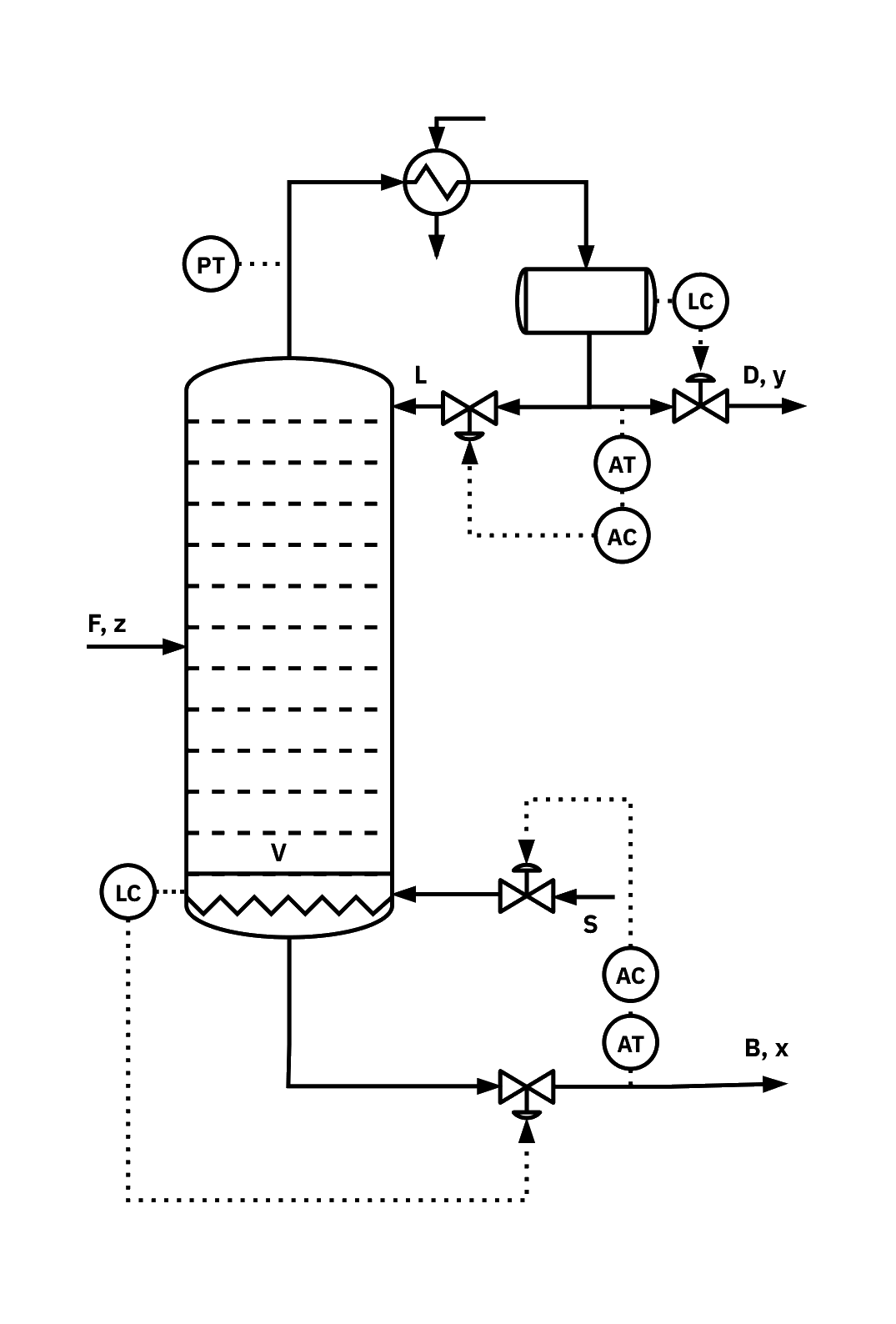

Distillation column: 2x2 MIMO example

- Two inputs: reflux flow L, steam/boilup S.

- Two outputs: distillate composition yD, bottoms composition xB.

- Interactions: changes in L or S affect both yD and xB.

- Level loop: weakly coupled to compositions.

- Design focus: composition controllers; choose pairings/decoupling to handle interactions.

Controller pairings

One major task in decentralized control system design → to select controller pairings

Controller pairings are chosen based on 3 main factors:

- Process Interactions

- Dynamic responses

- Sensitivity to disturbances

Improper controller pairings can lead to severe process interaction → causes poor control performance

Factors can be conflicting with each other

- e.g., pairings that lead to minimum process interactions may exhibit slow dynamic responses

- it is desirable to have fast dynamic responses.

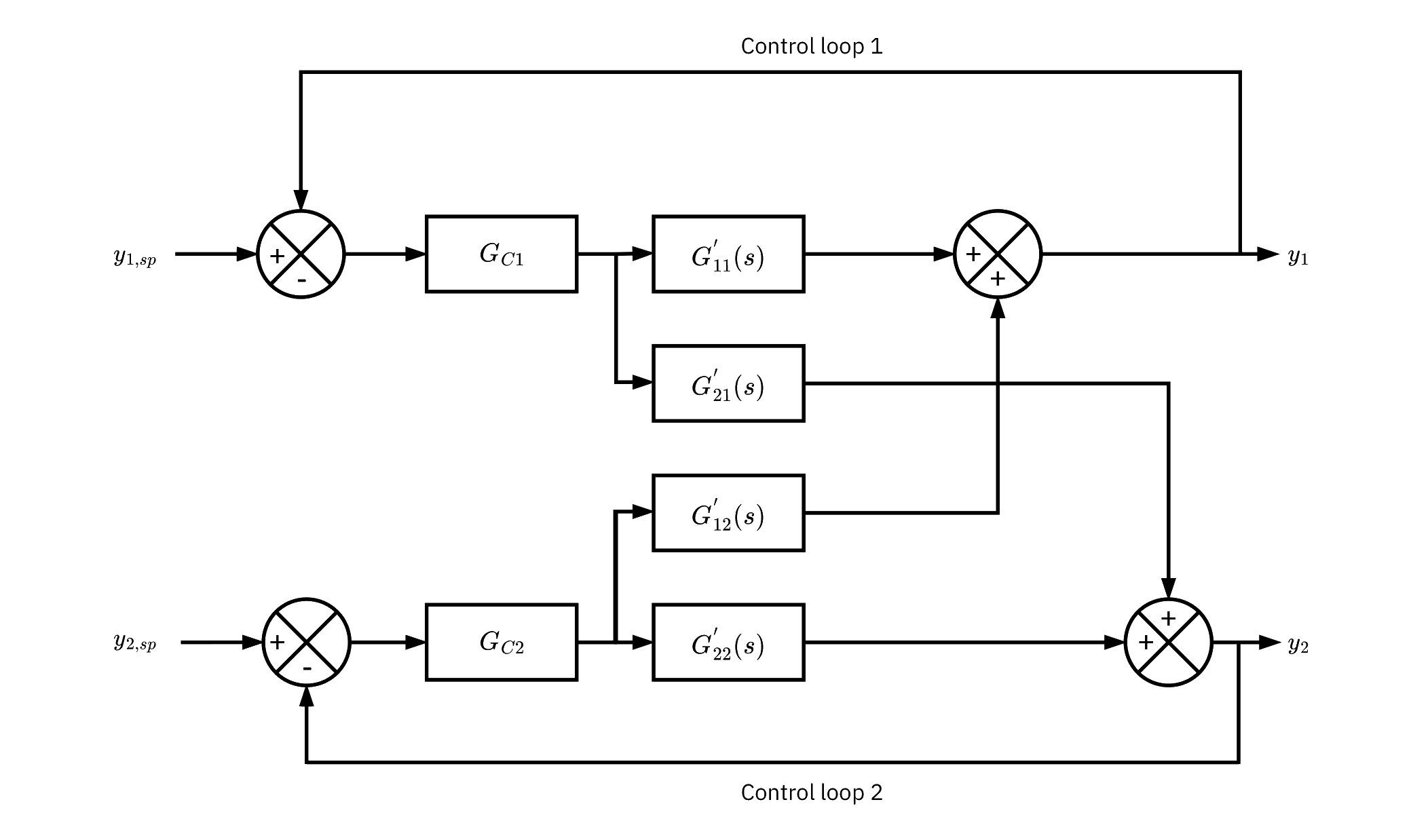

multi‐loop controllers (decentralized)

- Two SISO loops, two controllers.

- Independence is only valid when interactions are negligible.

- Cross terms G21′ and G12′ couple the loops and affect tuning.

- Direct pairings: c1→y1, c2→y2.

- Indirect pairings: c1→y2, c2→y1.

- Pairing choice changes interaction severity and overall performance.

Multi‐loop controllers – distillation column

- Reflux flow L controls top composition yD.

- Steam/boilup S controls bottom composition xB.

- Bottoms flow B maintains level.

- Top and bottom composition loops are strongly coupled, level loop coupling is weak.

- Select composition pairings to manage interactions. Compare L→yD, S→xB with the swapped pairing using gains, dynamics, and disturbance paths.

🤔

Can we control the top composition using the steam flow, while the bottom composition using the reflux flow? Why ?

Coupling effect of loop 2 on y1

- Change y1,sp → controller GC1 moves c1.

- c1 impacts y1 via G11′ and y2 via G21′.

- y2 deviates → GC2 adjusts c2.

- c2 impacts y2 via G22′ and y1 via G12′.

- Loop 1 reacts again to the cross effect on y1.

- The loops iterate until y1 and y2 settle, if no further setpoint or disturbance changes occur.

Multi‐loop controllers – distillation column

Reflux L holds the distillate composition yD; changing L also disturbs the bottoms composition xB.

The bottoms loop reacts: adjust steam/boilup S to bring xB back to its setpoint.

That change in S disturbs yD; the reflux loop trims L until yD returns to setpoint.

Relative Gain Array - steady-state interaction

- Relative Gain Array (RGA) is a steady-state interaction measure for MIMO systems.

Λ=K∘(K−1)T

K is the steady-state gain matrix of linearized plant. Its entries are the open-loop gains

K−1 is the inverse of K

(⋅)T is transpose,

∘ is the Hadamard (element-wise) product.

The RGA element is thus λij=kij(K−1)ji.

- For a 2×2 system

Λ=[λ11λ21λ12λ22]

λ11=λ22=1−k11k22k12k21 λ12=λ21=k11k22k12k21

- Properties

- Row and column sums: j∑λij=1i∑λij=1

- For 2×2, the diagonal terms are equal: λ11=λ22;λ11+λ12=1;λ21+λ22=1

Relative Gain Array - steady-state interaction

- For 2×2, only one element requires evaluation: λ11=main + coupling (2nd loop closed)(Δc1Δy1)y2(Δc1Δy1)c2main effect (2nd loop open)

- RGA for higher-order MIMO (3×3, 4×4)

- Definition stays the same: Λ=K∘(K−1)T

- Key properties for n×n:

- Row sums and column sums equal 1.

- Diagonals need not be equal and Λ need not be symmetric.

- Scale invariant, but operating-point dependent.

- RGA does not change if you rescale variables or change units

- RGA needs to be recomputed when the operating point shifts

RGA: coupling effect (interpretation of λ11)

λ11=1 — no coupling.

0<λ11<1 — coupling in the same direction as the main effect; severity grows as λ11↓.

At λ11=0.5: very severe.λ11>1 — coupling in the opposite direction; severity grows as λ11↑.

λ11<0 — sign reversal / very strong coupling; risk of closed-loop instability → avoid that pairing.

Choosing pairings for n×n:

- Select one element per row and column (a permutation) with positive λij near 1.

- Practical rule: minimize cost matrix Cij=∣λij−1∣ with an assignment method (for example Hungarian), or use a greedy pick (per row choose the available column with the smallest Cij and λij>0).

- Negative or near-zero λij indicates problematic pairings.

- Many large off-diagonals in a row or column imply strong interaction → consider decoupling or multivariable control.

RGA calculation

Given a 2×2 transfer-function matrix (FOPTD elements):

G(s)=τ11s+1k11e−θ11sτ21s+1k21e−θ21sτ12s+1k12e−θ12sτ22s+1k22e−θ22s

Steady-state gain matrix:

K=[k11k21k12k22]

Relative Gain Array:

Λ=K∘(K−1)T=[λ11λ21λ12λ22]

Diagonal element:

λ11=maink11−couplingk22k12k21k11=1−k11k22k12k211

MATLAB:

RGA analysis

Good for: assessing the steady-state coupling effect of a configuration.

Applicable when input/output relationships have the same general dynamic behaviors.

Pairing rules

- Prefer λij closest to 1 (weakest interaction).

- Avoid λij≤0 (sign reversal / integrity risk—one loop failure can destabilize the other).

- Ensure a one-to-one mapping (one element per row and column).

Caution: can be misleading if transfer-function dynamics are significantly different.

Bottom line: RGA is a steady-state measure of process interaction.

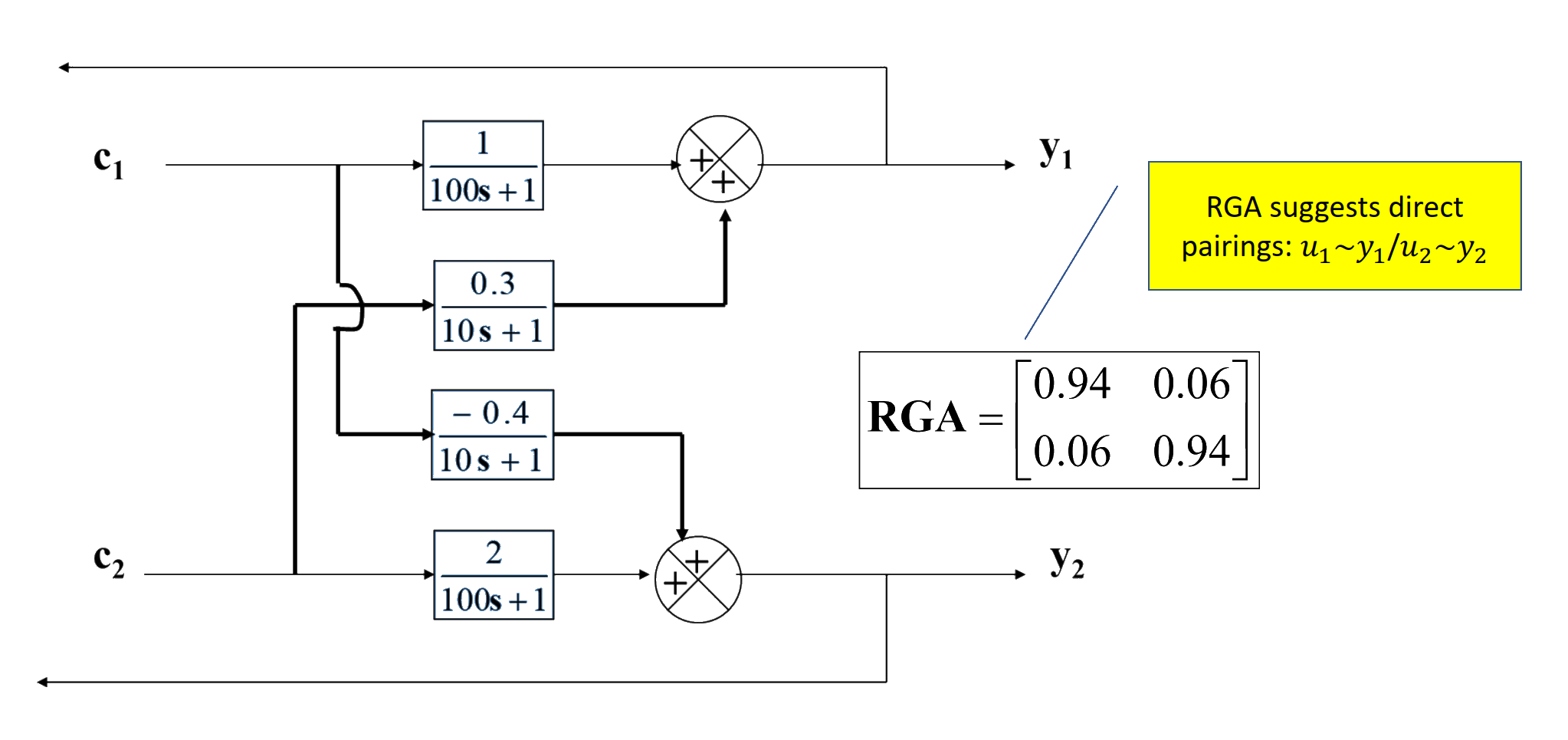

Impact of dynamic behavior

- Process Transfer Functions

G11(s)=100s+11.0,G12(s)=10s+10.3

G21(s)=10s+1−0.4,G22(s)=100s+12.0

- Steady-State Gain Matrix

K=[1.0−0.40.32.0]

- Relative Gain Array (RGA)

λ11=1−K11K22K12K211=1−(1.0)(2.0)(0.3)(−0.4)1=0.94

Λ=[0.940.060.060.94]

Impact of dynamic behavior

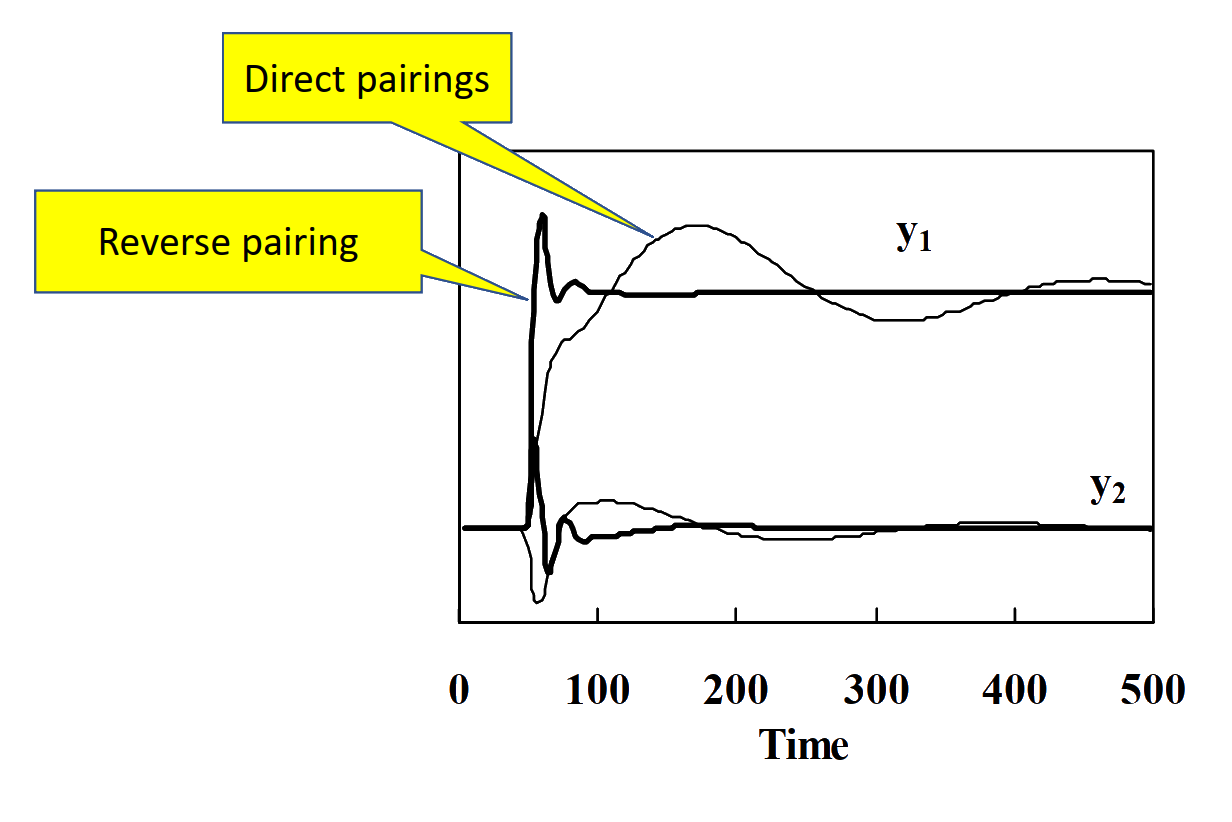

Direct vs reverse pairing

- RGA suggests direct pairings: u1→y1, u2→y2.

- But time-domain simulations show reverse pairings outperform direct pairings.

- Dynamic responses of two transfer functions differ (time constants 100 s vs 10 s).

- Steady-state RGA alone may be misleading; dynamic RGA is needed.

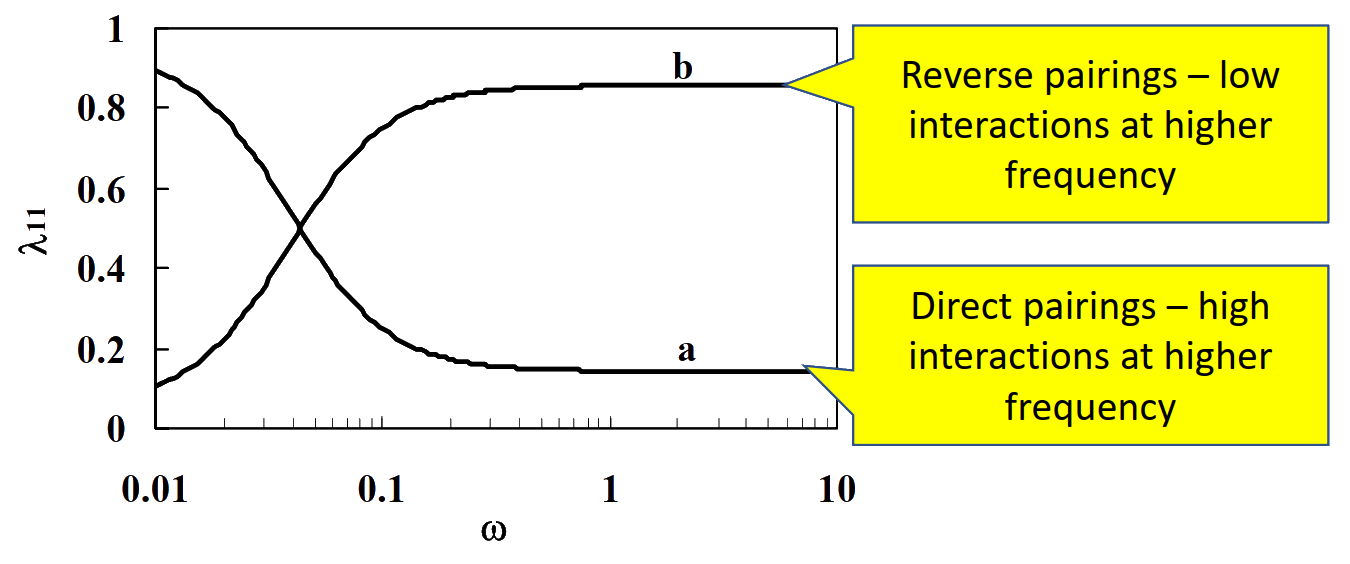

Dynamic RGA

When transfer function dynamics differ significantly, steady-state RGA can be misleading.

Dynamic RGA evaluates interaction strength as a function of frequency ω.

Helps identify correct pairings depending on operating frequency range.

- Mathematical Formulation

λ11(ω)=1−∣G11(iω)∣∣G22(iω)∣∣G12(iω)∣∣G21(iω)∣1

- For a first-order process:

∣G(iω)∣=τp2ω2+1Kp

- For the example system:

λ11(ω)=1+1002ω2+116.7(1002ω2+1)1

Pairing Considerations

Choose pairing between manipulated and controlled variables that results in the least process interactions.

- Use steady-state RGA for comparable dynamics.

- Use dynamic RGA for dissimilar dynamics.

Choose pairing that leads to quick response of controlled variable to manipulated variable (fast dynamic criterion).

Example:

U1Y1=10s+12e−s,U2Y1=12s+12e−3s

Prefer U1∼Y1 because U1 responds faster. U2 has longer deadtime, which reduces achievable control performance.

Choose pairing that is least sensitive to disturbance.

Key Insights

- Direct pairings can suffer at higher frequency if dynamics are mismatched.

- Reverse pairings may be more effective at higher frequency, even if steady-state RGA suggests otherwise.

- Rule of thumb:

- Low frequency operation → direct pairings

- High frequency operation → reverse pairings

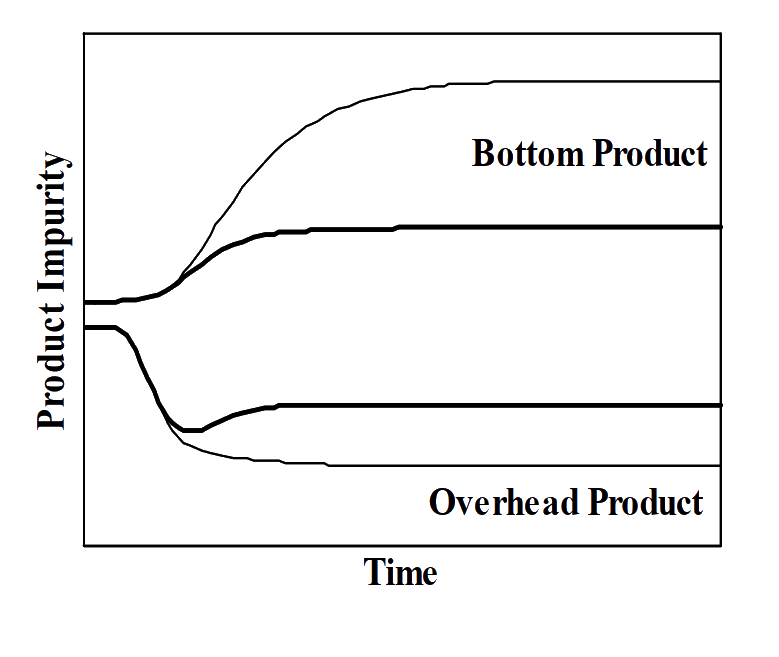

Sensitivity to disturbances

Each configuration has a different sensitivity to a disturbance.

Thick and thin line represent the results of different configurations.

Notice that, the configuration with thick line is less sensitive to disturbance than the one with thin line.

The one that is less sensitive to disturbance is a more efficient configuration (or pairings).

Less sensitive to disturbance is also good because it could lead to lower control action required.

Example ‐ configuration selection for a C3 splitter

| Configuration | RGA (λ₁₁) | Comment |

|---|---|---|

| (L, B) | 0.94 | Least interactions |

| (L, V) | 25.3 | Severe interactions – coupling effect opposite to main effect |

| (L/D, V/B) | 1.70 | Mild interactions |

| (D, V) | 0.06 | Mild interactions – coupling effect in same direction as main effect; main effect weaker than coupling effect |

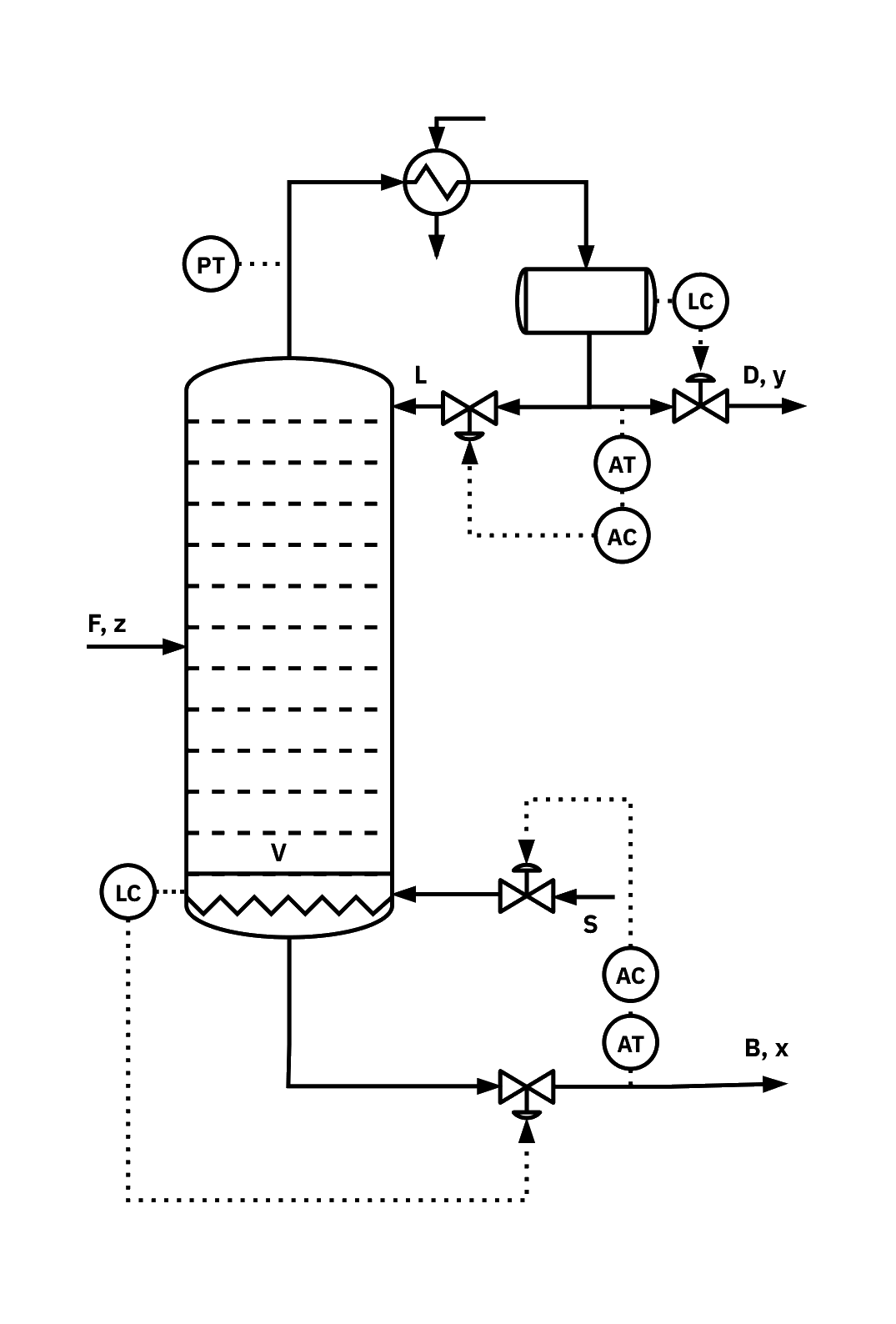

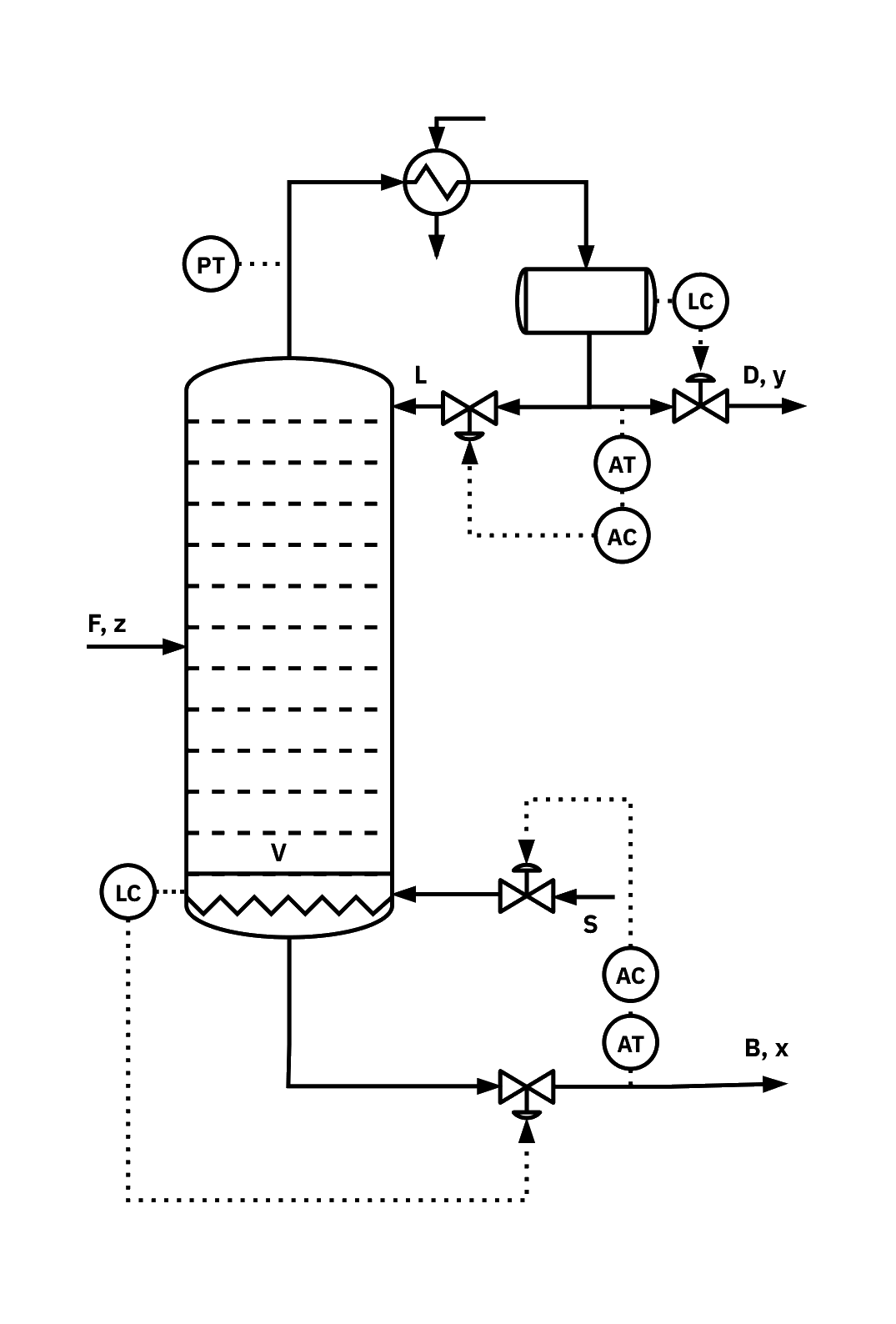

(L,V) configuration applied to the C3 splitter

- Reflux flow L is used to control top composition

- Steam flow S is used to control bottom composition

- Steam flow directly affects vapor flow V in the column → therefore V is used to control the bottom composition

- This arrangement is known as the (L,V) configuration

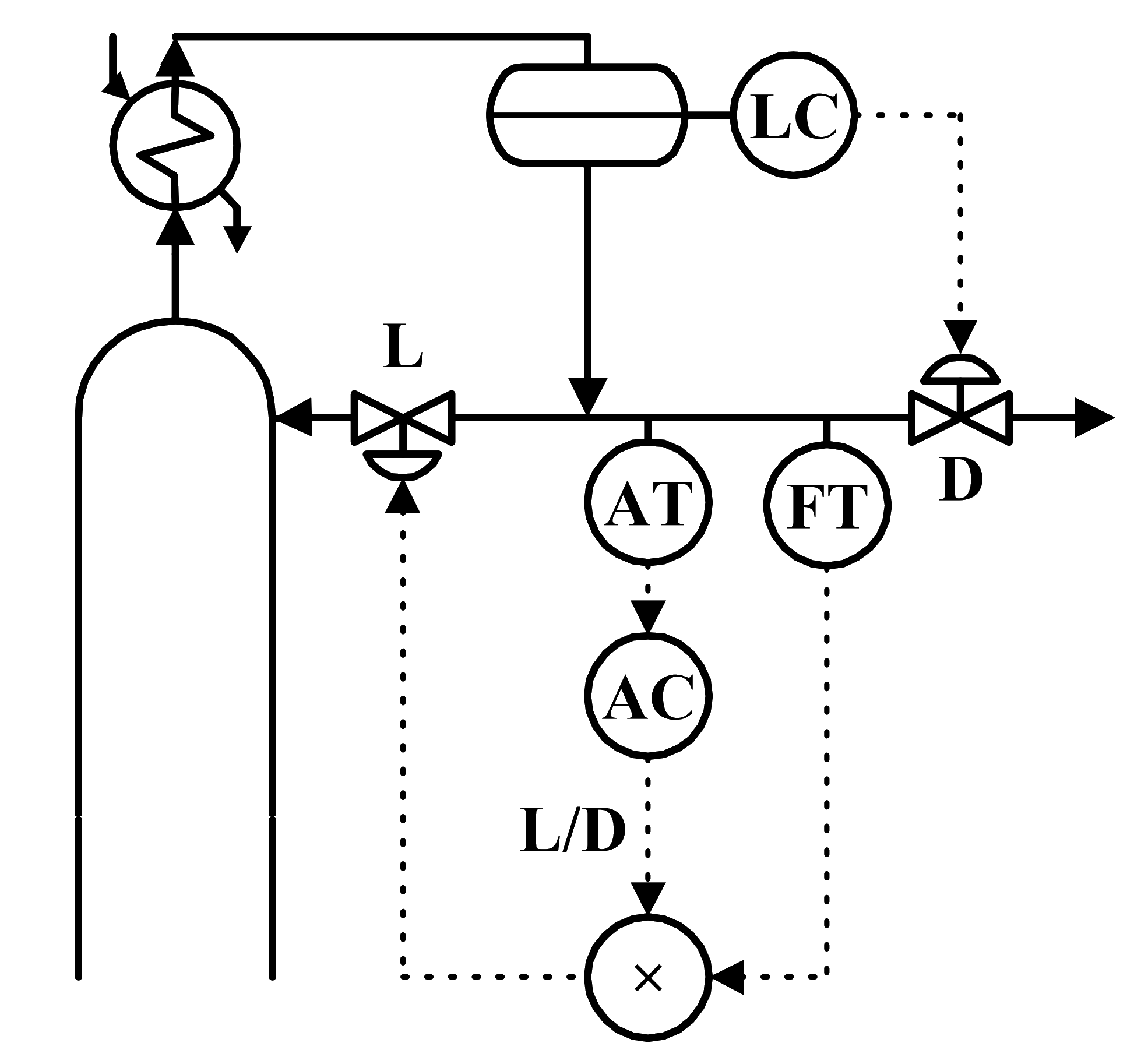

Reflux ratio applied to the overhead of the C3 splitter

- Ratio controller is used where the wild stream is the distillate flow, while the reflux stream is the manipulated flow

- Thus, reflux ratio (L/D) is used as manipulated variable by the top composition controller

- For the bottom composition controller, the boilup ratio (V/B) can be used as manipulated variable

- Bottom flow B is wild stream

- Steam flow S is the manipulated stream (S is directly related to vapor flow

- Bottom flow B is wild stream

- Thus, this is called the (L/D, V/B) configuration

Other configurations

- (L,B) configuration

- Reflux flow L is used to control top composition

- Bottom flow B is used to control bottom composition

- (D,V) configuration

- Distillate flow D is used to control top composition

- Steam flow (related directly to V) is used to control bottom composition

Configuration selection of C3 splitter

L, L/D and V are the least sensitive to feed composition disturbances

L and V have the most immediate effect on the product compositions

L/D and V/B give an intermediate effect

D and B yield the slowest response

Each configuration involves conflicting factors

- Example: (L,V) is the least sensitive to disturbance and has fast dynamic response

- But it exhibits the most severe process interaction (λ11 = 25.3)

- Example: (L,V) is the least sensitive to disturbance and has fast dynamic response

Therefore, simulation is required to evaluate configuration performance

Control performance

| Configuration | IAE for Overhead | IAE for Bottoms |

|---|---|---|

| (L, B) | 0.067 | 1.49 |

| (L, V) | 0.250 | 13.3 |

| (L/D, V/B) | 0.095 | 2.00 |

| (D, V) | 0.098 | 1.91 |

- (L,B) configuration gives the smallest IAE for the overhead controller

- Indicates best top controller performance

- Also corresponds to the configuration with least interactions

Analysis of configuration selection example

- (L,V) is the worst configuration

- It is the least susceptible to disturbances and the fastest acting configuration

- But it is the most coupled (λ11 = 25.3)

- It is the least susceptible to disturbances and the fastest acting configuration

- (D,V) has an RGA of 0.06 but shows decent control performance

- D has slow dynamic, V has fast dynamic

- If both had fast or both had slow dynamics, this configuration might show poor performance

- D has slow dynamic, V has fast dynamic

- (L,B) is the best configuration

- Provides good decoupling

- Overhead product is most important

- Provides good decoupling

Multi‐loop (decentralized) pid controller design

There are six main categories of methods to design multi-loop PID control systems:

- Detuning

- Sequential loop closing

- Independent tuning

- Simultaneous tuning

- Optimization

- Relay auto-tuning

Key Idea

Each method offers a different balance of: - Simplicity vs. performance

- Handling of interactions

- Practical implementation effort

Detuning method

- Step 1: An individual controller is tuned according to an existing single-input and single-output tuning formula, e.g., classical Ziegler-Nichols and Skogestad IMC

- Example: consider 2 multi-loop PID controllers

Gc1=Kc1(1+τI1s1+τD1s),Gc2=Kc2(1+τI2s1+τD2s)

- Example: consider 2 multi-loop PID controllers

- Step 2: Detune each controller by a factor F

- Detuned controllers

Gc1′=FKc1(1+τI1s1+τD1s),Gc2′=FKc2(1+τI2s1+τD2s)

- Detuned controllers

- Step 3: Evaluate the closed-loop responses – if not satisfied then readjust F

Example 2x2 MIMO – Wood and Berry (WB) column

- The Wood and Berry column is represented by the transfer function matrix

G=[16.7s+112.8e−s10.9s+16.6e−7s21s+1−18.9e−3s14.4s+1−19.4e−3s]

- RGA analysis

Λ=[2.0094−1.0094−1.00942.0094]

- Recommended pairings: U1→Y1 and U2→Y2 (direct pairings)

- Direct pairings ensure RGA elements are positive

- Always avoid negative RGA pairings

WB column - detuning method

Apply Ziegler-Nichols tuning (Matlab Control System Designer) to design two PID controllers

Design PID 1 based on

g11=16.7s+112.8e−s

Gc1=1.2895(1+2s1+0.4602s),GM=5.02dB,PM=34.9∘Design PID 2 based on

g22=14.4s+1−19.4e−3s

Gc2=−0.2548(1+5.6s1+1.4s),GM=4.88dB,PM=40.1∘

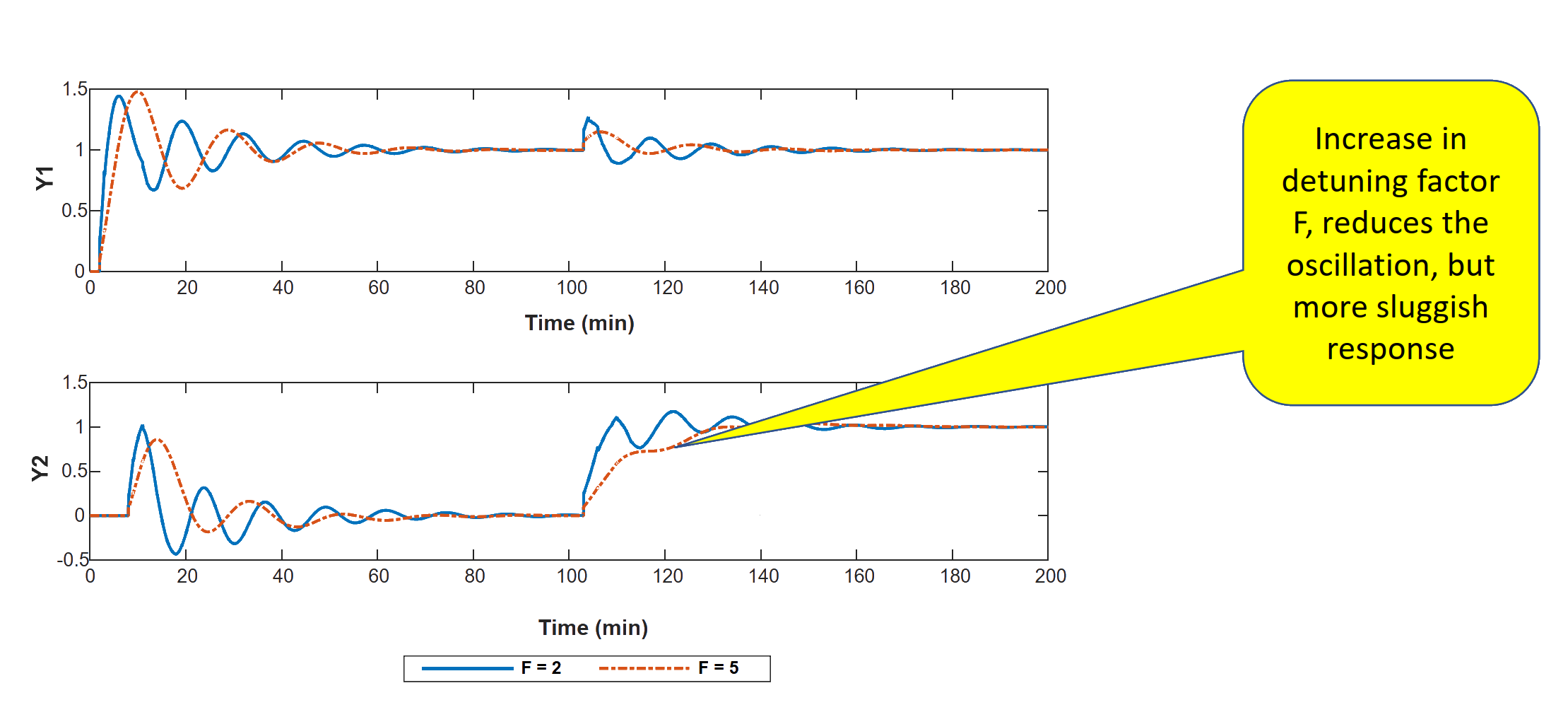

WB column - detuning method

If F = 2

Gc1′=0.6448(1+2s1+0.4602s),Gc2′=−0.1274(1+5.6s1+1.4s)If F = 5

Gc1′=0.2579(1+2s1+0.4602s),Gc2′=−0.0510(1+5.6s1+1.4s)

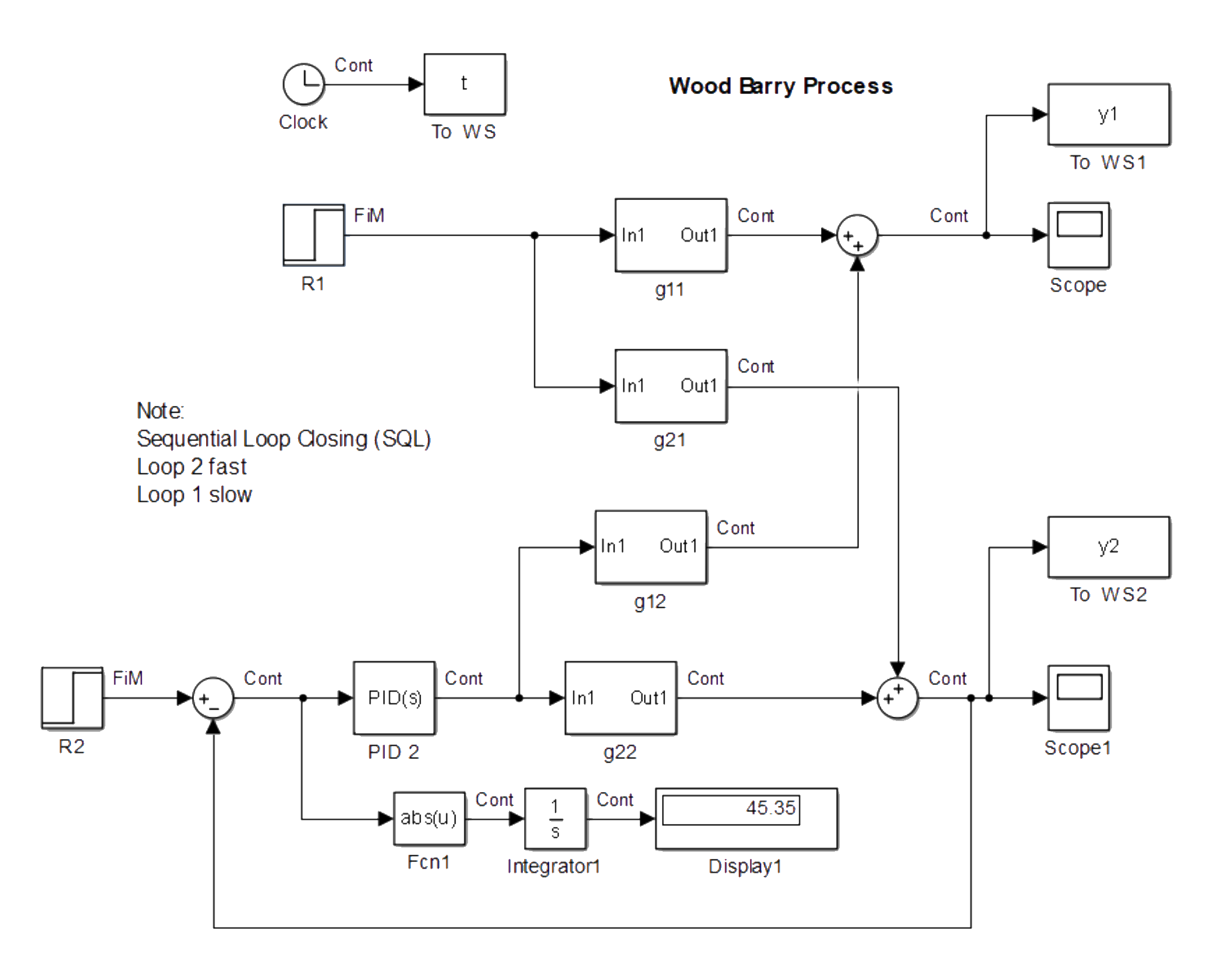

Sequential loop (SQL) closing

- Steps

- Choose the fast loop first, before the slower one

- Design the controller for the faster loop using its transfer function

- Close the fast loop (activate controller)

- Derive a linearized model for the slower loop with the fast loop already closed

- Design the second controller using the linearized model

- Close the second (slower) loop

- Choose the fast loop first, before the slower one

- For additional loops, repeat steps 4 to 6

The order of loop closing is critical as it strongly influences overall control performance

WB column – SQL method

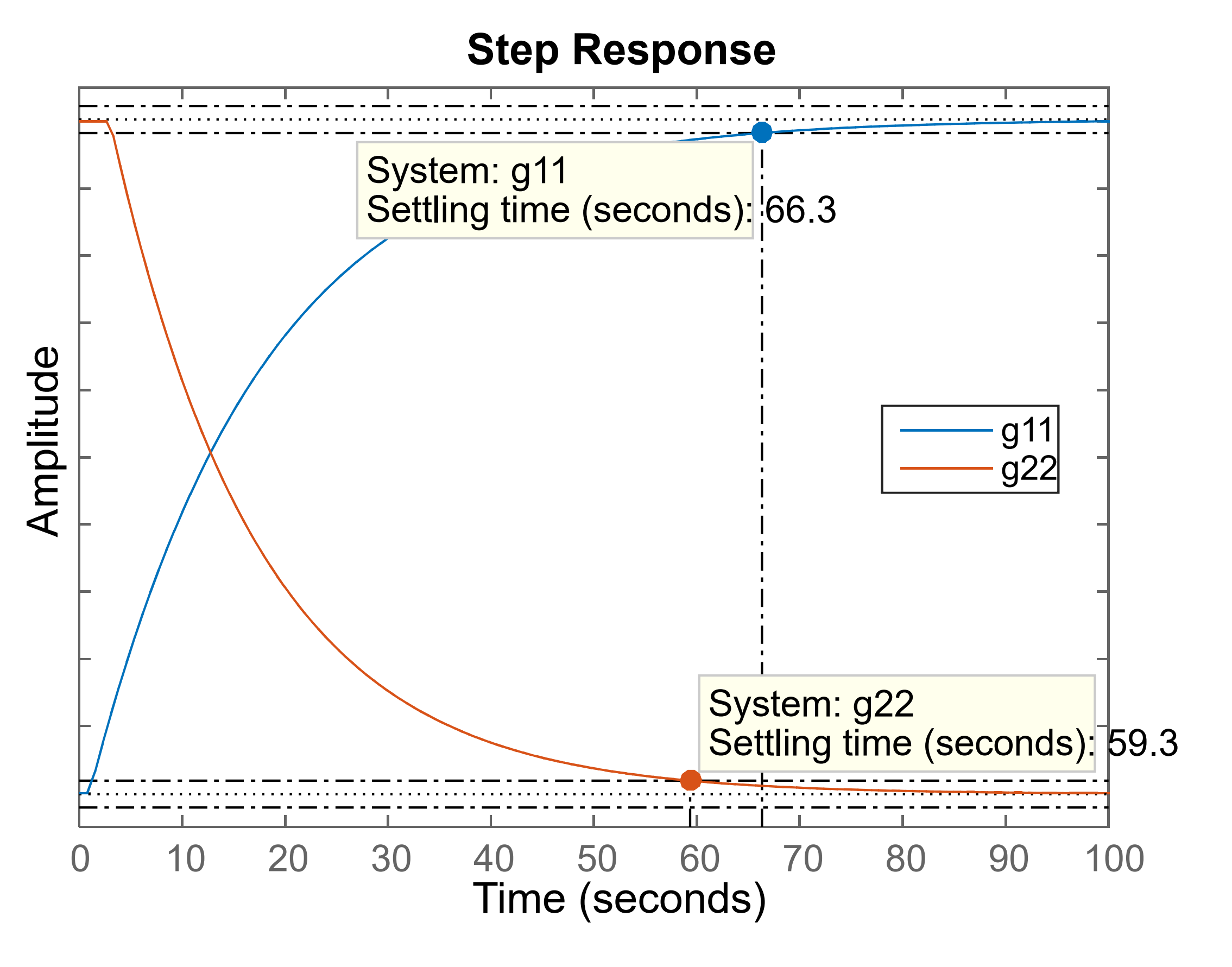

Step 1: Identify which loop is faster by comparing open-loop step responses of g11 and g22

Use Matlab commands:

- From the step responses:

- g22 has a shorter settling time (59.3 s)

- g11 has a longer settling time (66.3 s)

- Therefore, loop 2 is faster than loop 1

- g22 has a shorter settling time (59.3 s)

Sequential loop closing example

use skogestad imc (simc) tuning in matlab control system designer

design pid 2 using g22

gc2=−0.1423(1+16.5s1+1.3636s)

gm=9.71db,pm=74.8∘

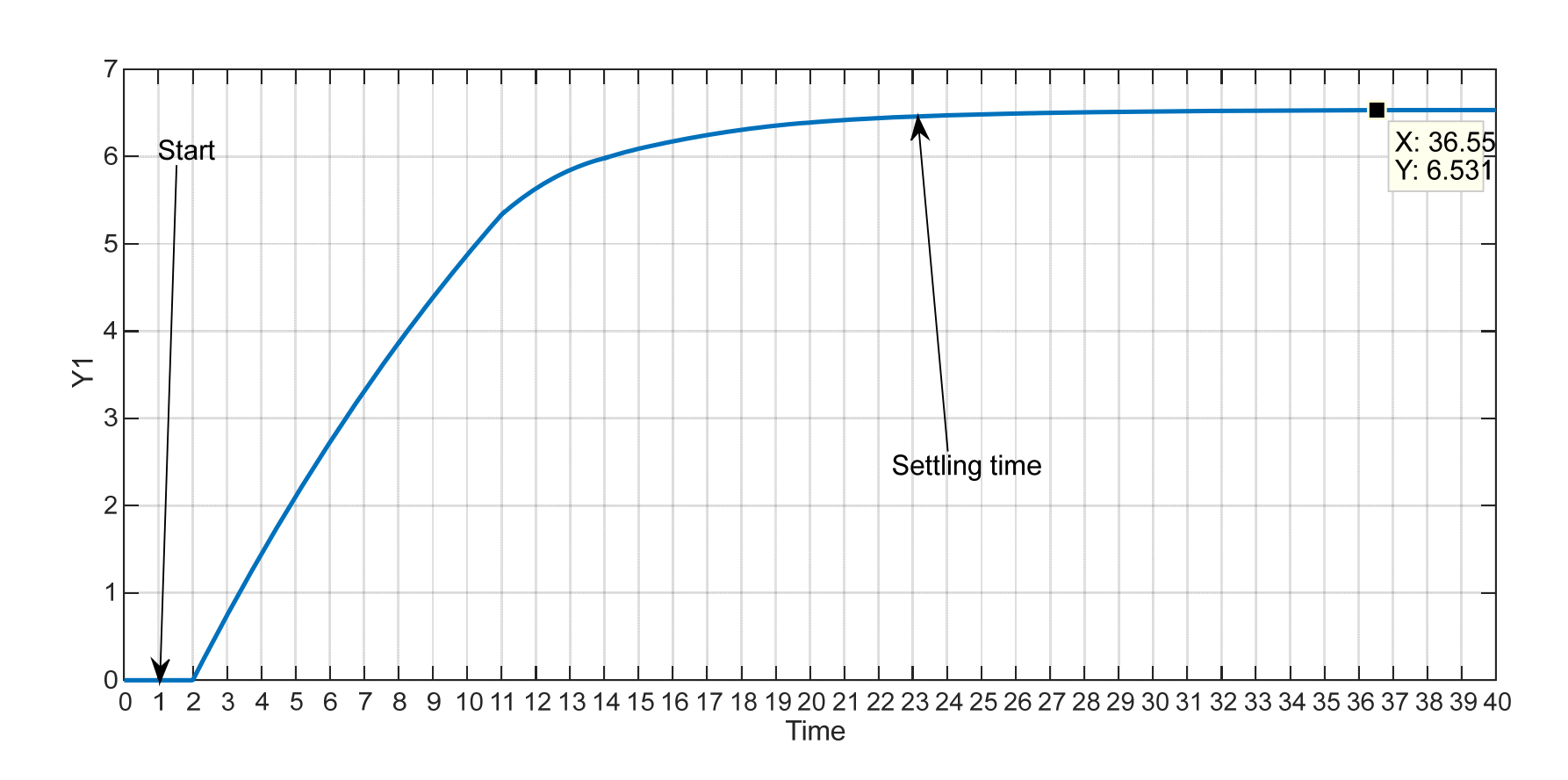

apply a 1-unit step change in r1 and plot t against y1

from this step response, obtain the fopdt parameters (to be used in the next step)

Sequential loop closing example

- from the step response of y1:

- delay: θ=1

- time constant: τp=423−2=5.25

- gain: kp=6.53

- delay: θ=1

linearized model for loop 1:

g11′=5.25s+16.53e−s

Sequential loop closing example

design pid 1 using the linearized model g11′

g11′=5.25s+16.53e−s

gc1=0.4405(1+5.7s1+0.456s)

gm=9.92db,pm=74.6∘

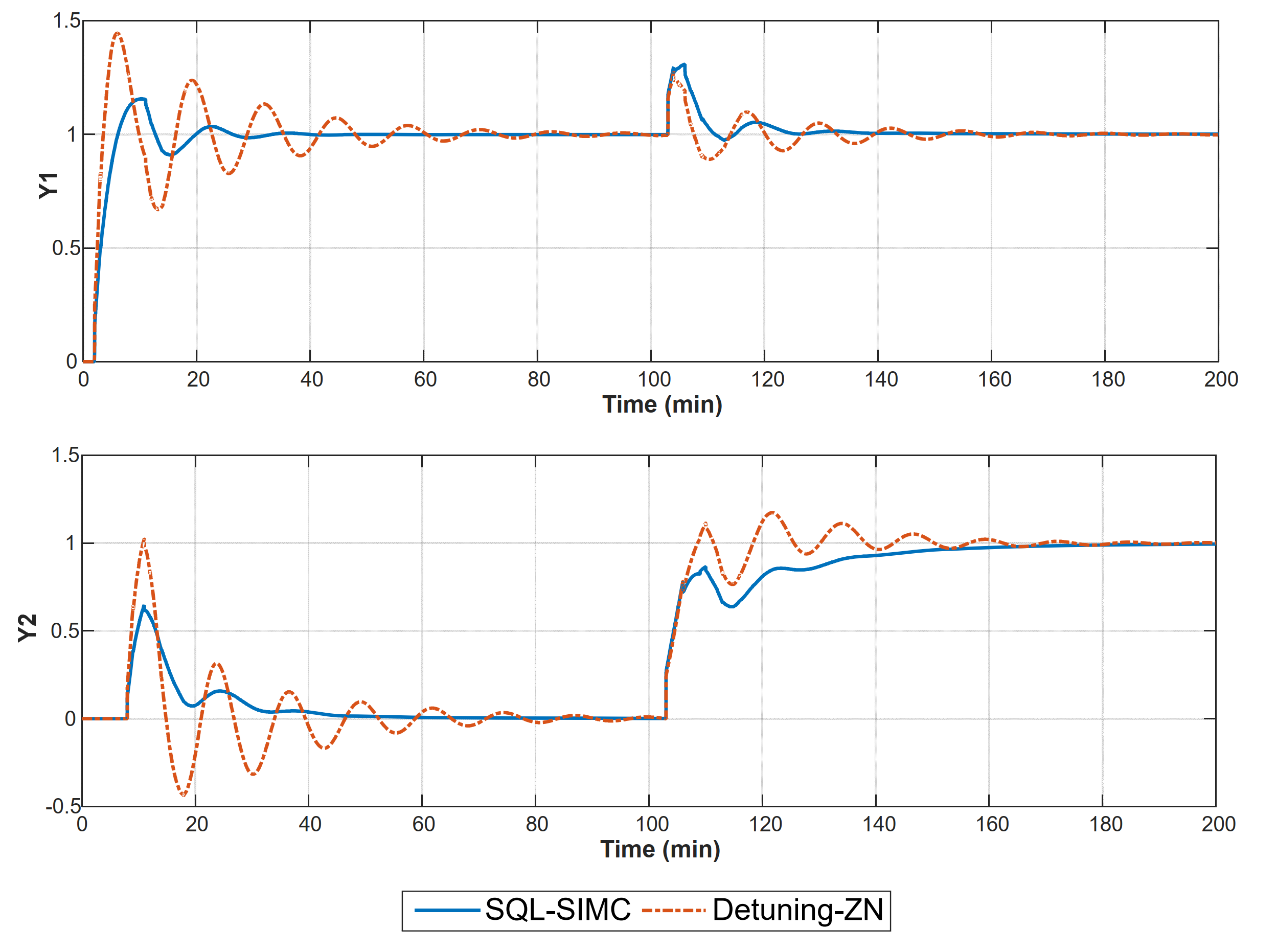

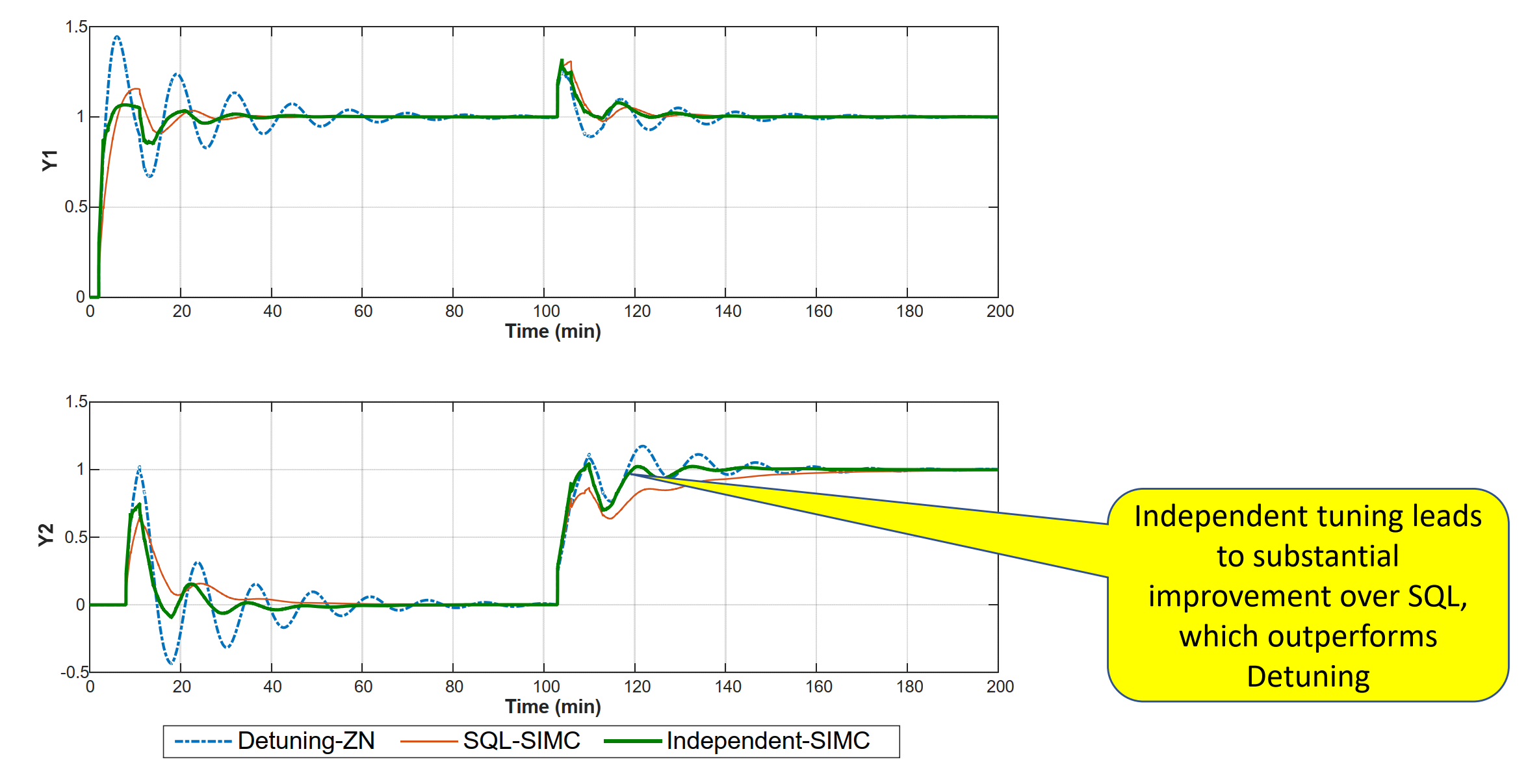

the plots show comparison between sql tuning and the previous detuning method

sql demonstrates substantial improvement in closed-loop performance compared to detuning

Independent tuning method

Independent tuning method relies on the Effective Open-Loop Transfer Function (EOTF)

For a 2×2 MIMO transfer function matrix:

G=[g11g21g12g22]

Reduce to decentralized form:

G=[ge1100ge22]

- EOTFs:

ge11=g11−g22g12g21,ge22=g22−g11g12g21

Controllers Gc1 and Gc2 are designed independently based on ge11 and ge22

Existing SISO tuning formulas can be used

Next, we illustrate application of independent tuning for the Wood and Berry column example

Multi‐loop pid controllers for WB column – independent tuning method

- Recall WB column transfer function:

G=16.7s+112.8e−s10.9s+16.6e−7s21s+1−18.9e−3s14.4s+1−19.4e−3s

Effective Open-Loop Transfer Functions (EOTFs):

ge11=16.7s+112.8e−s−14.4s+1−19.4e−3s(21s+1−18.9e−3s)(10.9s+16.6e−7s)

ge11=16.7s+112.8e−s−(21s+1)(10.9s+1)6.43(14.4s+1)e−7s

Multi‐loop pid controllers for WB column – independent tuning method

Approximation is required to simplify the EOTF

Equalize delays of main and coupling transfer functions

Assume general formula:

g=(τ1s+1)(τ2s+1)kpe−(θ1+θ2)s≈(τ1s+1)(τ2s+1)(θ2s+1)kpe−θ1s

Applying to coupling transfer function:

ge11≈(21s+1)(10.9s+1)(6s+1)6.43(14.4s+1)e−s

Overall EOTF for loop 1:

ge11=[16.7s+112.8−(21s+1)(10.9s+1)(6s+1)6.43(14.4s+1)]e−s

This simplified transfer functions can be used in Matlab Control System Designer since they contain only a single delay term

Multi‐loop pid controllers for WB column – independent tuning method

The second EOTF can be derived in the same manner

Overall EOTF for loop 2:

ge22=[14.4s+1−19.4+(21s+1)(10.9s+1)(6s+1)9.745(16.7s+1)]e−3s

Controller Design using Skogestad IMC Tuning

- For ge11:

Gc1=0.775(1+8.5s1+0.471s)

GM=8.96dB,PM=75.2∘

- For ge22:

Gc2=−0.16(1+9.3s1+1.258s)

GM=9.27dB,PM=78.7∘

Multi‐loop pid controllers for WB column – independent tuning method

Summary

Decentralized or multi-loop PID control is widely applied in process industries

Multi-loop control is often implemented at the regulatory layer, crucial for achieving stability

Proper controller pairing is essential in decentralized design to handle process interactions

Relative Gain Array (RGA) is used to address the configuration issue

Use steady-state RGA when transfer function dynamics are comparable

Use dynamic RGA when transfer function dynamics differ significantly

Correct pairing and RGA analysis are critical for robust and stable multi-loop control

Advanced Modeling and Control