Other advanced control techniques

Advanced Modeling and Control

Outline

Objectives of Plant Control

Process Control Roles and Plant Objectives

Process Constraints – why important?

PID Control Enhancement Strategies

- Override Control

- Inferential Control

- Scheduling Controller Tuning

- Computed Manipulated Variable

Objectives of plant control

Safety

Equipment Protection

Environmental Protection

Smooth Operation

Profit

These objectives are interrelated.

Process safety

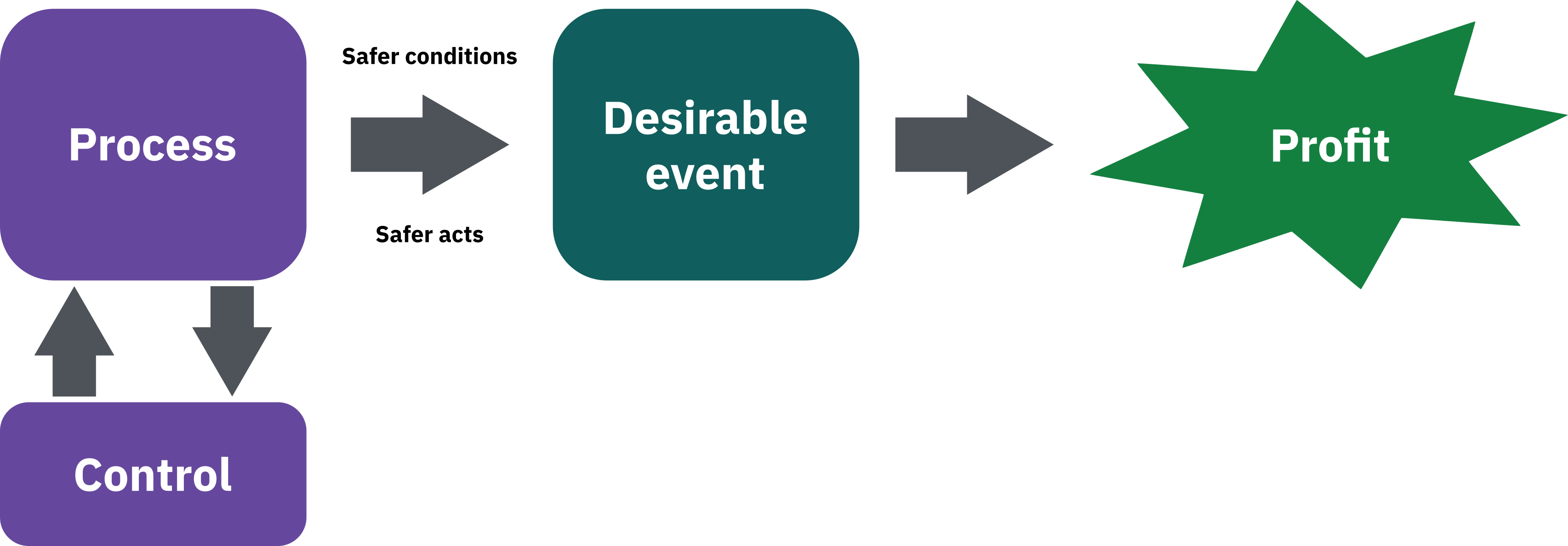

Accidents occur due to unsafe conditions and unsafe acts resulting from improper control.

![]()

Proper process control ensures safer conditions and along with safer acts, leads to safe and profitable operations.

![]()

Process safety

- Safety: Ensuring operations are free of any accidents.

- Causes of Accidents:

- Unsafe Conditions

- Unsafe Acts

- Addressing These Factors:

- Implementing Advanced Control Systems: Automated shutdown systems, Real-time data monitoring Predictive maintenance tools

- Enhancing Safety Training: Regular safety drills, Clear communication of safety procedures, Continuous education on best practices and new technologies

- Enforcing Safety Protocols: Strict adherence to safety guidelines, Use of personal protective equipment (PPE), Encouraging a culture of safety and accountability

- Mitigation through Proper Control Systems:

- Unsafe Conditions:

- Implement automated monitoring and control systems.

- Use sensors and alarms to detect and address hazardous conditions.

- Ensure regular maintenance and inspections to keep equipment in optimal condition.

- Unsafe Conditions:

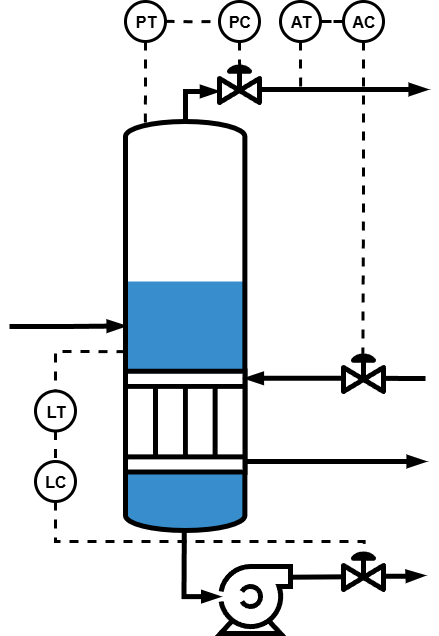

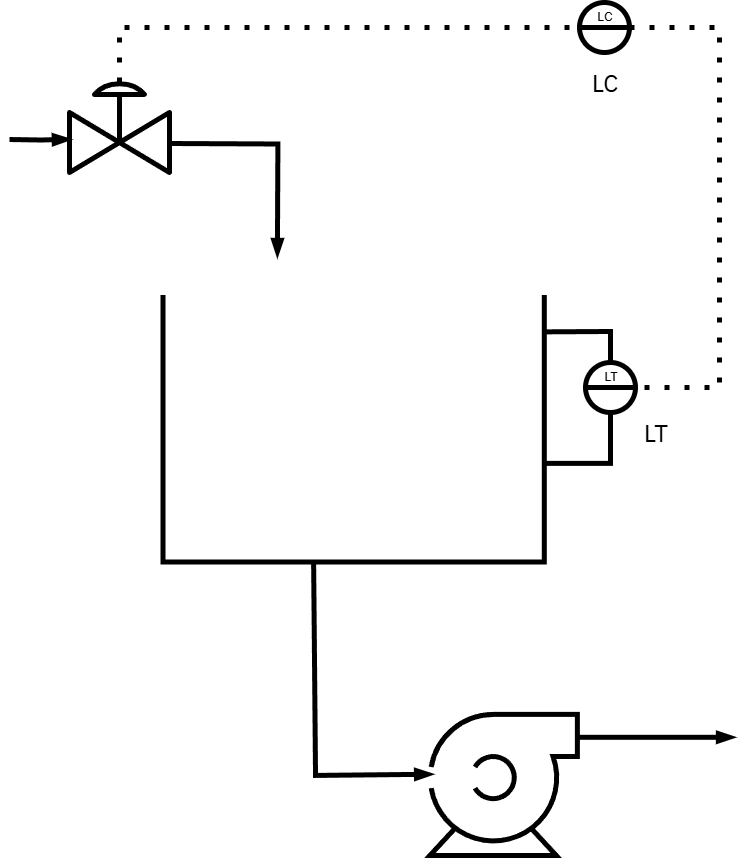

Unsafe conditions

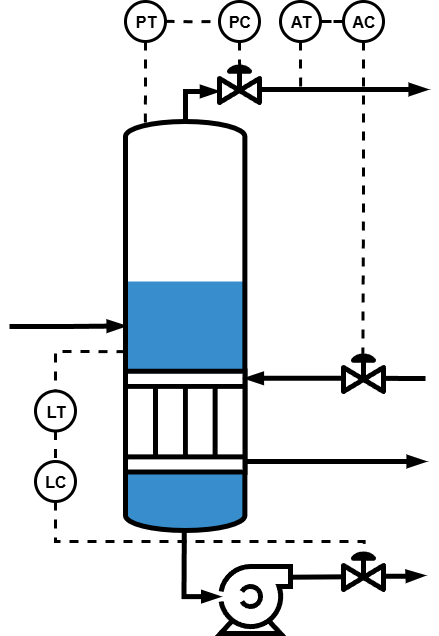

A feed stream containing acidic and toxic solution is fed into a tank. A pump is placed underneath the tank.

Describe how an unsafe condition can arise from the operation.

What kind of accidents that can be triggered by the unsafe condition?

Prevention of unsafe conditions

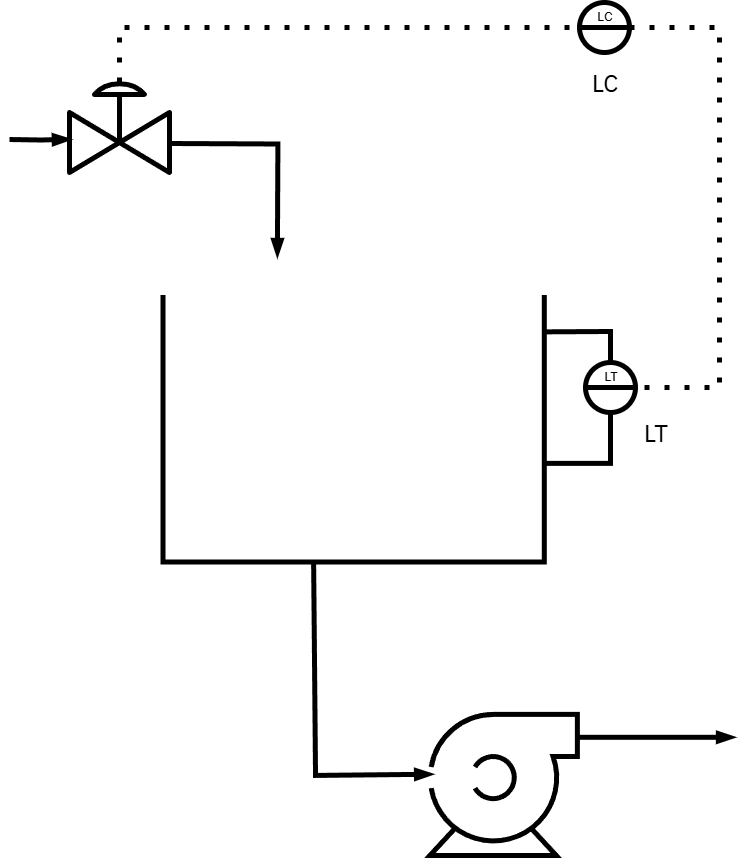

Applying Control to Liquid Levels:

- Ensures liquid spillover prevention.

Liquid Level Control:

- Prevents Liquid Spillover

- Achieves Control Objectives

- Enhances Safety

- Both safety and equipment protection are interrelated.

Additional Benefits of Liquid Control:

- Improves Pump Operations: Ensures consistent liquid levels, preventing pump cavitation and prolonging pump lifespan. Reduces maintenance costs and downtime.

Environmental protection

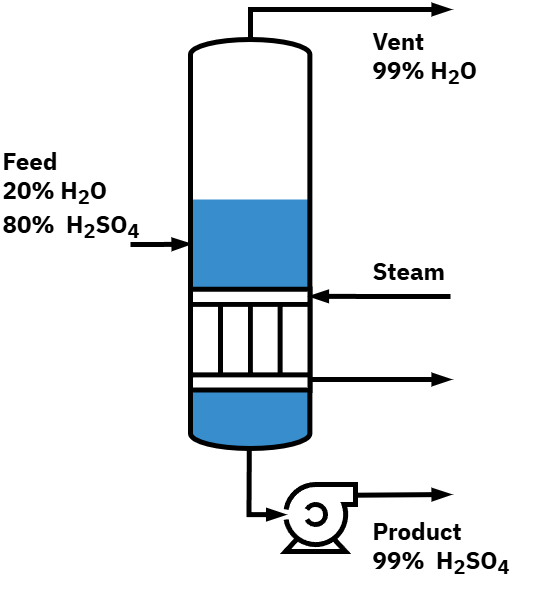

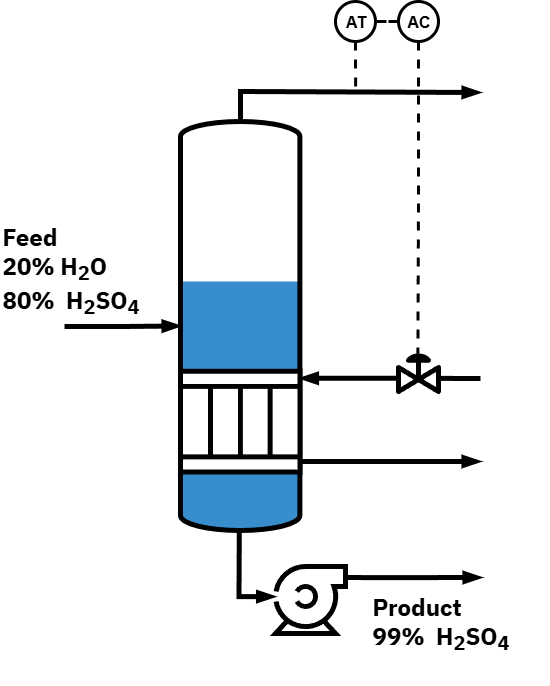

Flash Tank Feed containing 20% water and 80% HX2SOX4. Product must be at least 99% pure HX2SOX4

Vent discharge should not be more than 1% HX2SOX4, otherwise violates an environmental regulation.

Describe how can the vent discharge exceed 1% limit?

What damages can arise if the limit discharge is exceeded?

What is the implication of this violation on sustainability?

Environmental protection

By controlling the HX2SOX4 mass fraction in the vapor using steam flow rate, it can ensure that the limit will not be violated during operation.

The question becomes, is this control strategy sufficient?

Do we need to address safety and equipment Protection issues?

Environmental protection

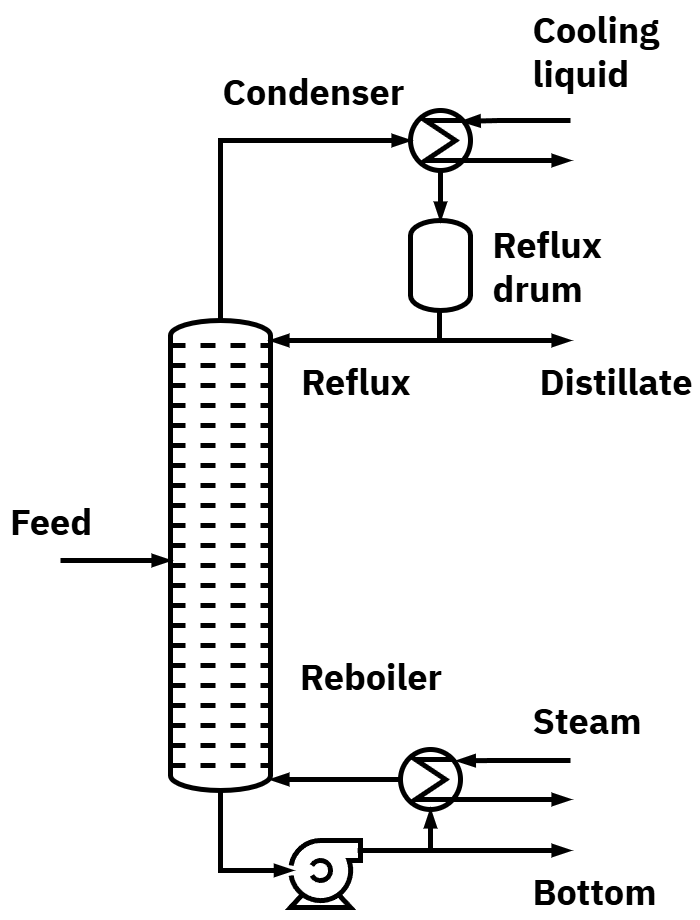

Smooth operations: distillation column

Distillation Column is an important unit in many chemical plants.

Objective: To separate components based on differences in volatility, ensuring the desired purity of products.

Key Variables: Temperature, pressure, reflux ratio, and feed composition.

The column has several control objectives.

Can you identify which control loop is related to smooth operation?

Operating constraints

Soft constraints

- Can be violated during operation without compromising safety.

Hard constraints

- Physical limitations, such as maximum flow rates determined by valve sizes.

- Constraints directly related to safety, which must never be violated.

Dealing with Process Constraints is important to prevent accidents, unnecessary process disruptions, and loss in profit.

Conventional PID controllers are NOT able to handle constraints.

Override Control Strategies are used to deal with constraints.

- Which are hard constraints?

- Which are soft constraints?

Operating constraints

- Which are hard constraints?

- Which are soft constraints?

Limitations of conventional PID controllers

- Measurement Deadtime:

- Delay between the process variable’s actual change and the time it is measured.

- Delayed corrective actions, leading to poor control and potential process upsets.

- Process Nonlinearity:

- PID controllers are designed for linear systems, but many real-world processes exhibit nonlinearity.

- Degraded control performance, oscillations, or instability in nonlinear processes.

- Process Constraints:

- Physical or safety-related constraints that PID controllers are not inherently equipped to manage.

- Risk of constraint violations, which can lead to safety hazards or equipment damage.

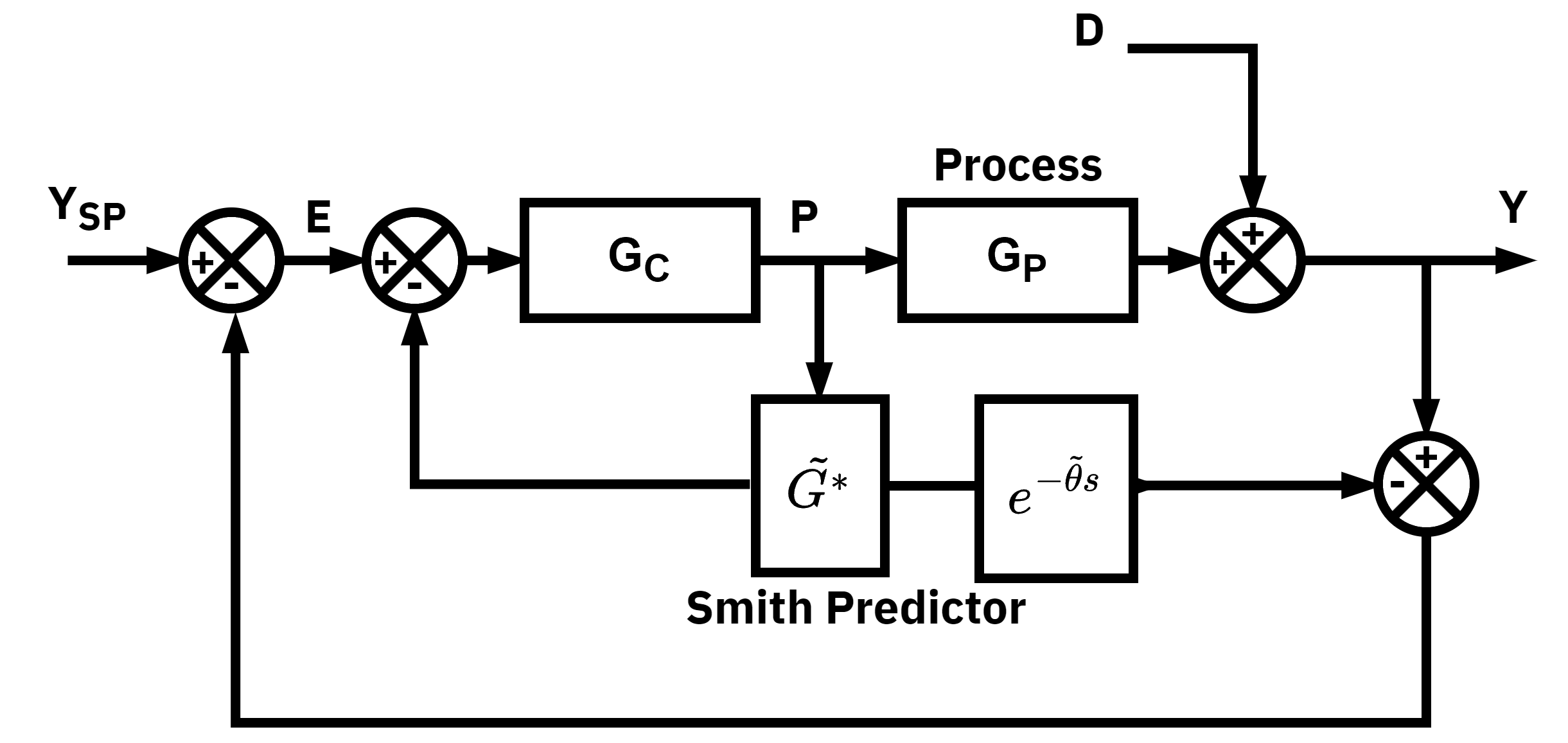

Effect of Deadtime on Control Performance

Smith predictor

Inferential control

A control strategy that estimates (infers) unmeasured process variables based on other easily measurable variables and uses these estimates to maintain control of the process.

Some critical variables are difficult or expensive to measure directly (e.g., product composition, purity).

Uses Easily Measured Process Variables (e.g., Temperature, Pressure, Flow Rate)

- Mathematical models to more difficult-to-measure quantities such as compositions and molecular weight.

Advantages

- Reduces Analyzer Delay: Provides faster estimations, improving process responsiveness.

- Cost-Effective: Significantly lowers both capital and operating costs compared to direct measurement systems.

- Unique Measurements: Offers insights into variables that may be difficult or impossible to measure directly.

- Key Requirement: The inferential measurement must correlate strongly with the controlled variable of interest to ensure accurate and reliable control.

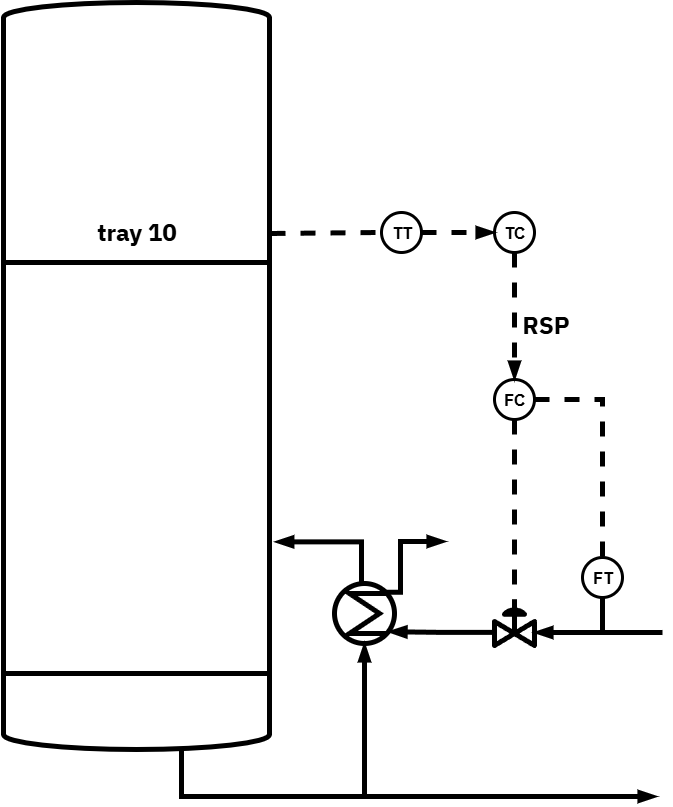

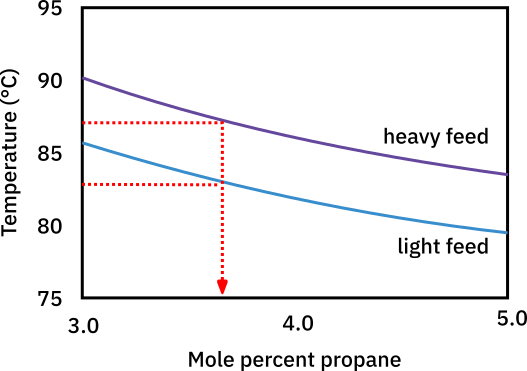

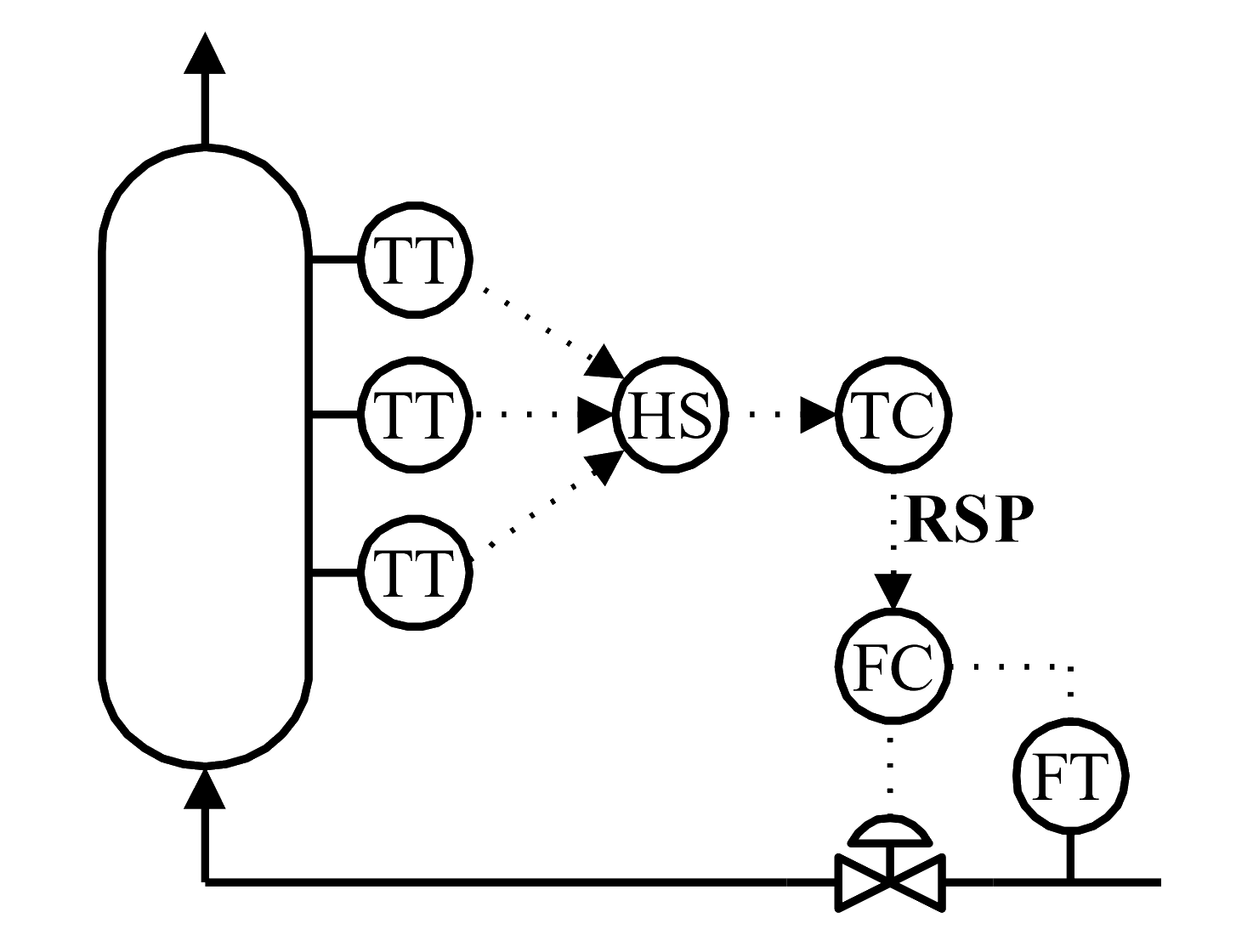

Inferential temperature control for distillation columns

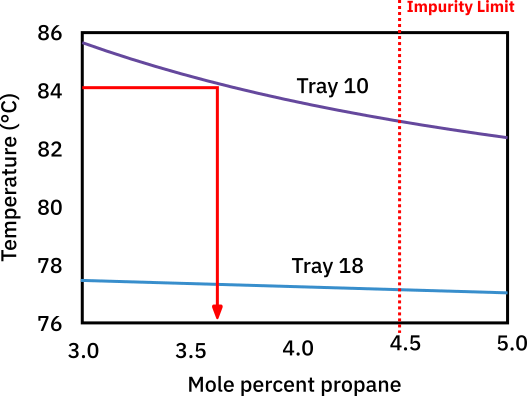

Choosing a proper tray temperature location

A tray temperature used for inferential control should show strong sensitivity.

Tray 10 is more sensitive ⇒ change in % mol of propane clearly represented by T

Tray 18 is not sensitive to change in % mol of propane ⇒ change from 3.5% to 4% only leads to very small error signal in temperature

Larger error signal generated in temperature ⇒ more effective inferential T control of %mol of propane

Composition/Temperature correlation

Tray temperature for multicomponent distillation column as a function of the light key in the bottoms product for different ratios of heavy non-key to light non-key

Feed composition affects the composition-temperature correlation.

Tray temperature cannot represent the bottom composition well enough when feed composition heavily fluctuates

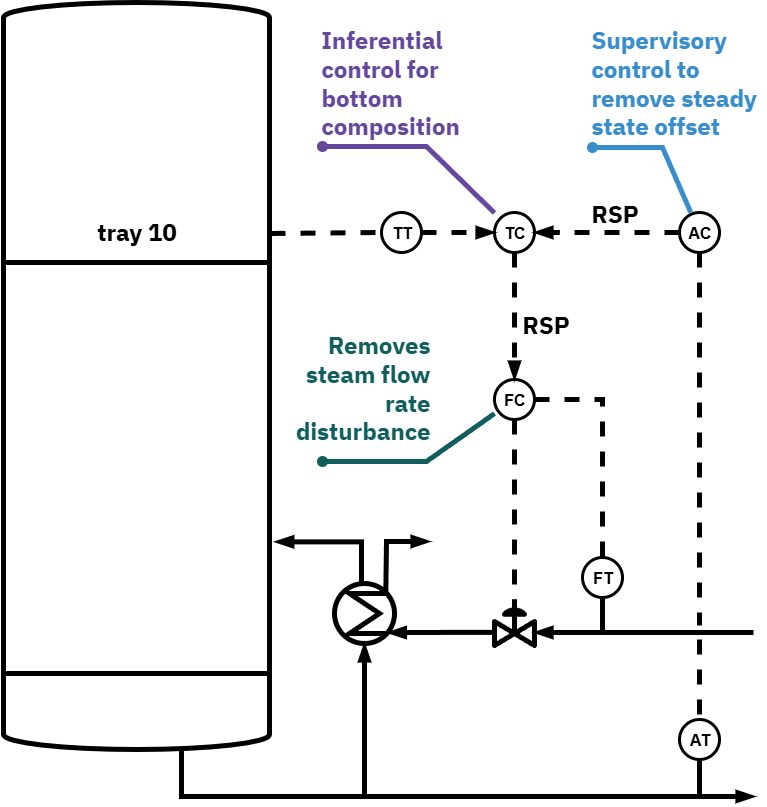

Feedback correction: feed composition changes

The inferential T controller is now a slave to the composition controller

Advantages: remove extra disturbances, e.g., feed flow rate and temperature disturbances

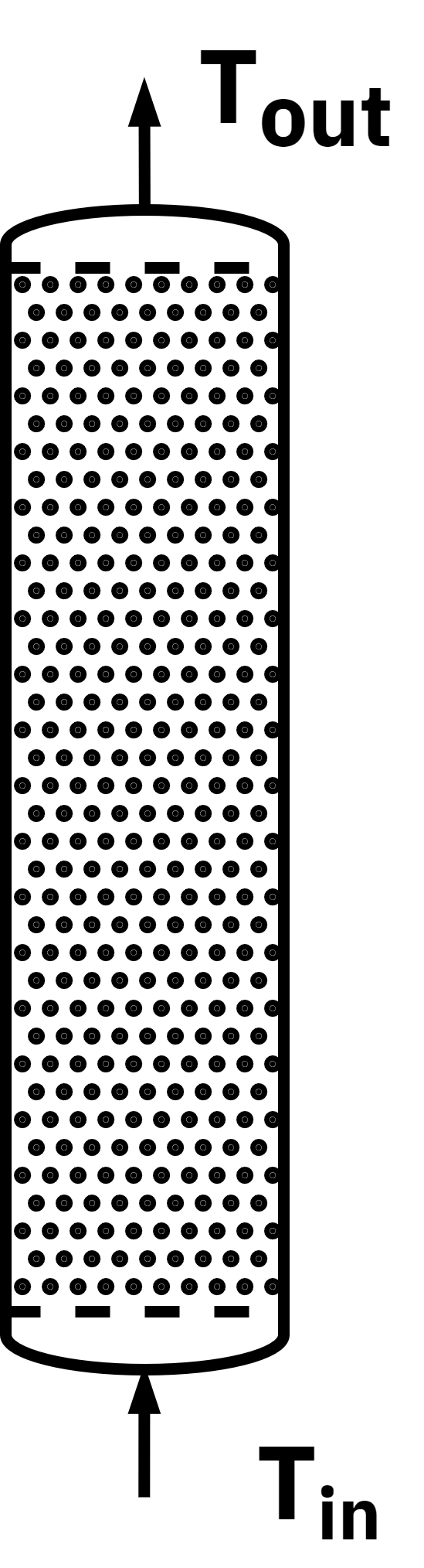

Inferential Reactor Conversion Control

Macroscopic energy balance

XACAin(−ΔHrxn)=ρCp(Tout−Tin)

XA=CAin(−ΔHrxn)ρCp(Tout−Tin)

- Develop linear relationship based on plant data

XA=a(Tout−Tin)+b

- Temperature difference across the reactor must be large enough;

- noise on the temperature measurement has a minimum effect on XA

- Inlet composition and physical properties are constants, or do not change significantly.

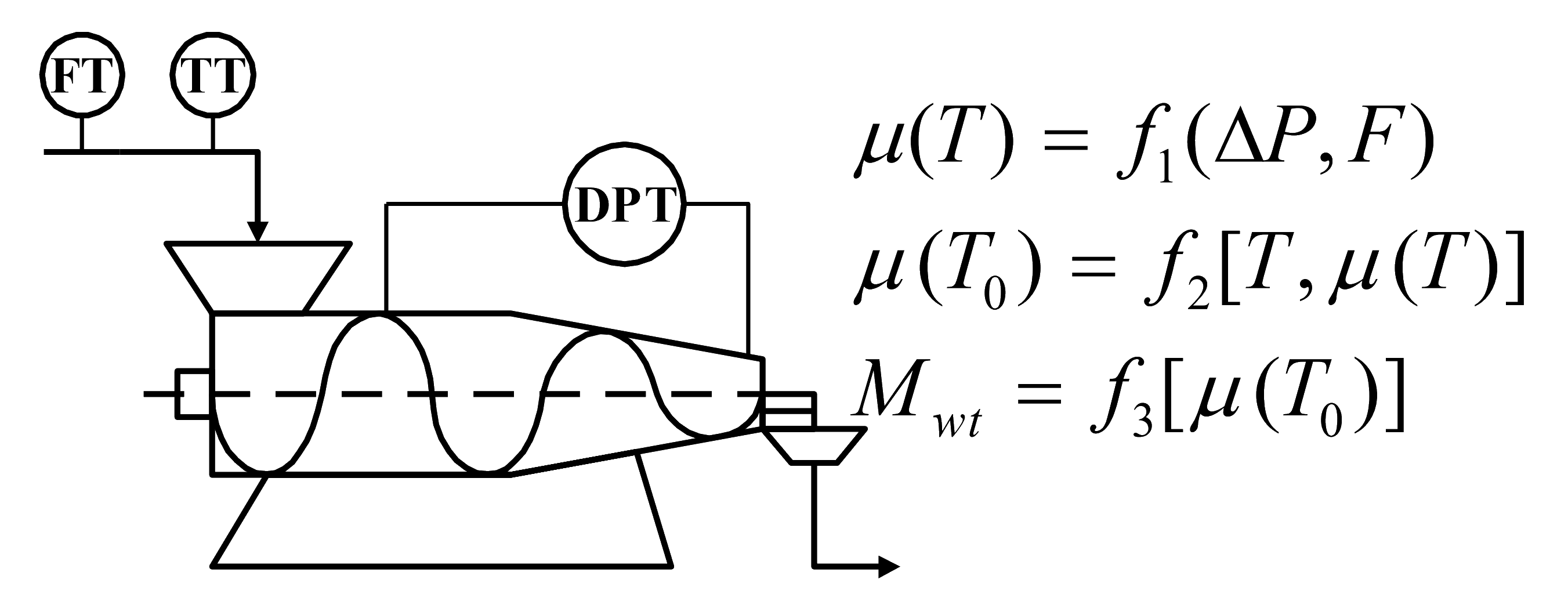

Molecular Weight of a Polymer

- Without inferential, samples requires about 10 hrs test in the lab.

- Long deadtime will seriously reduce the control performance

- Deadtime imposes an upper limit on the control performance

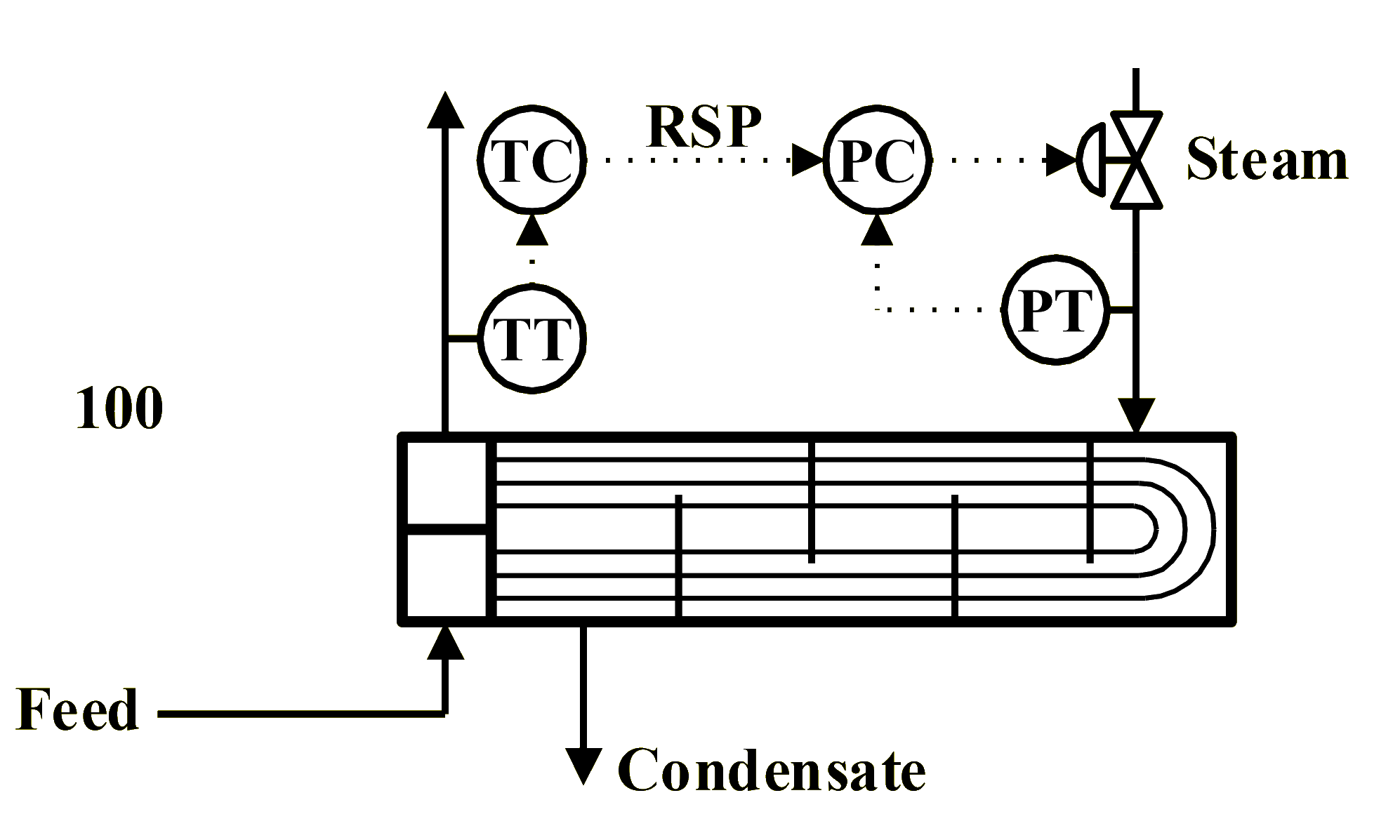

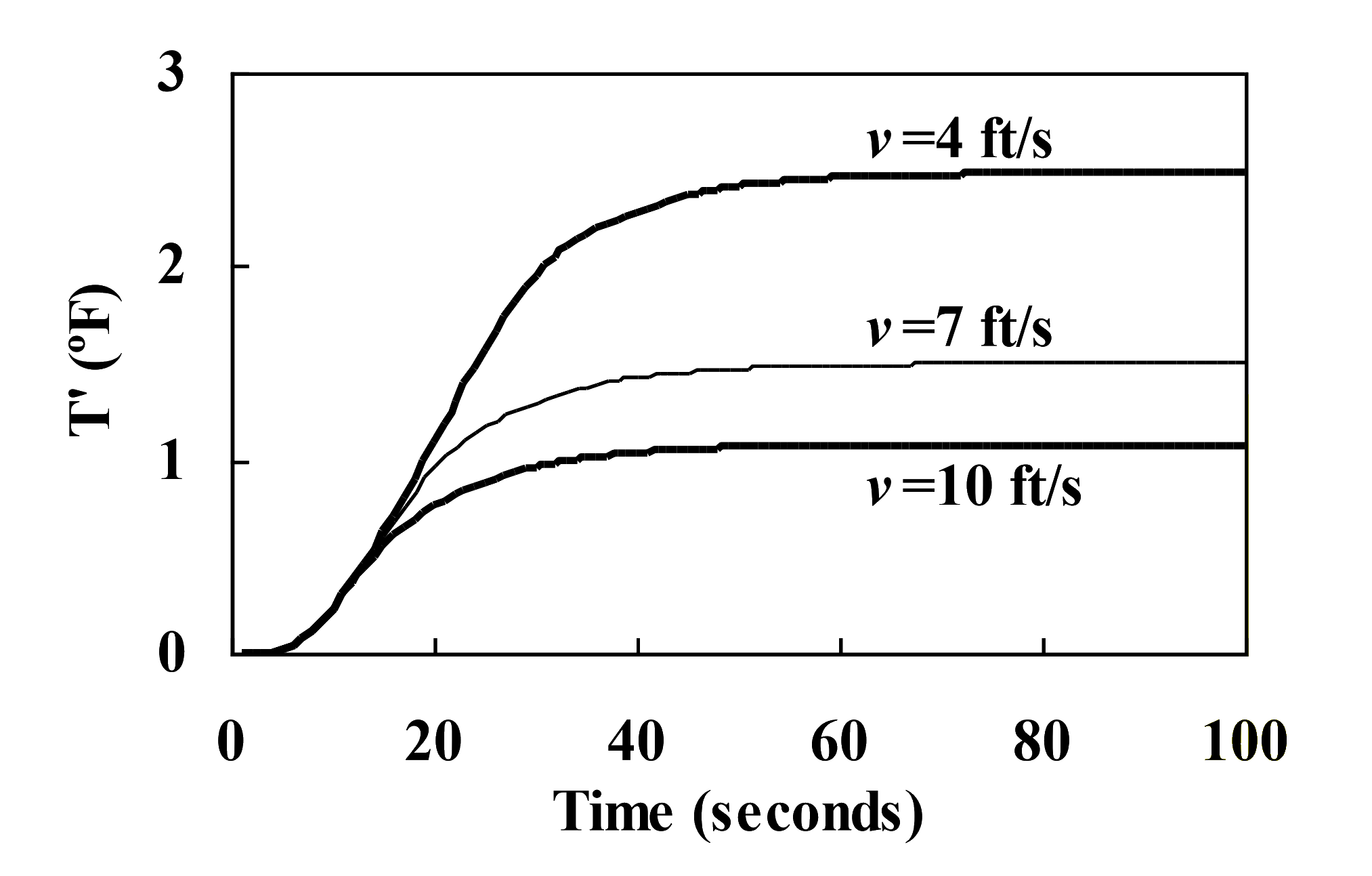

Gain scheduling

Equipment response is nonlinear to input changes

- Heat exchangers are nonlinear with respect of flow rate changes

Can be effective When either a measured disturbance or, The controlled variable correlates with Nonlinear process changes

Tune the controller at different levels, scheduling parameters; and combine the results so that the controller tuning parameters vary over the full operating range.

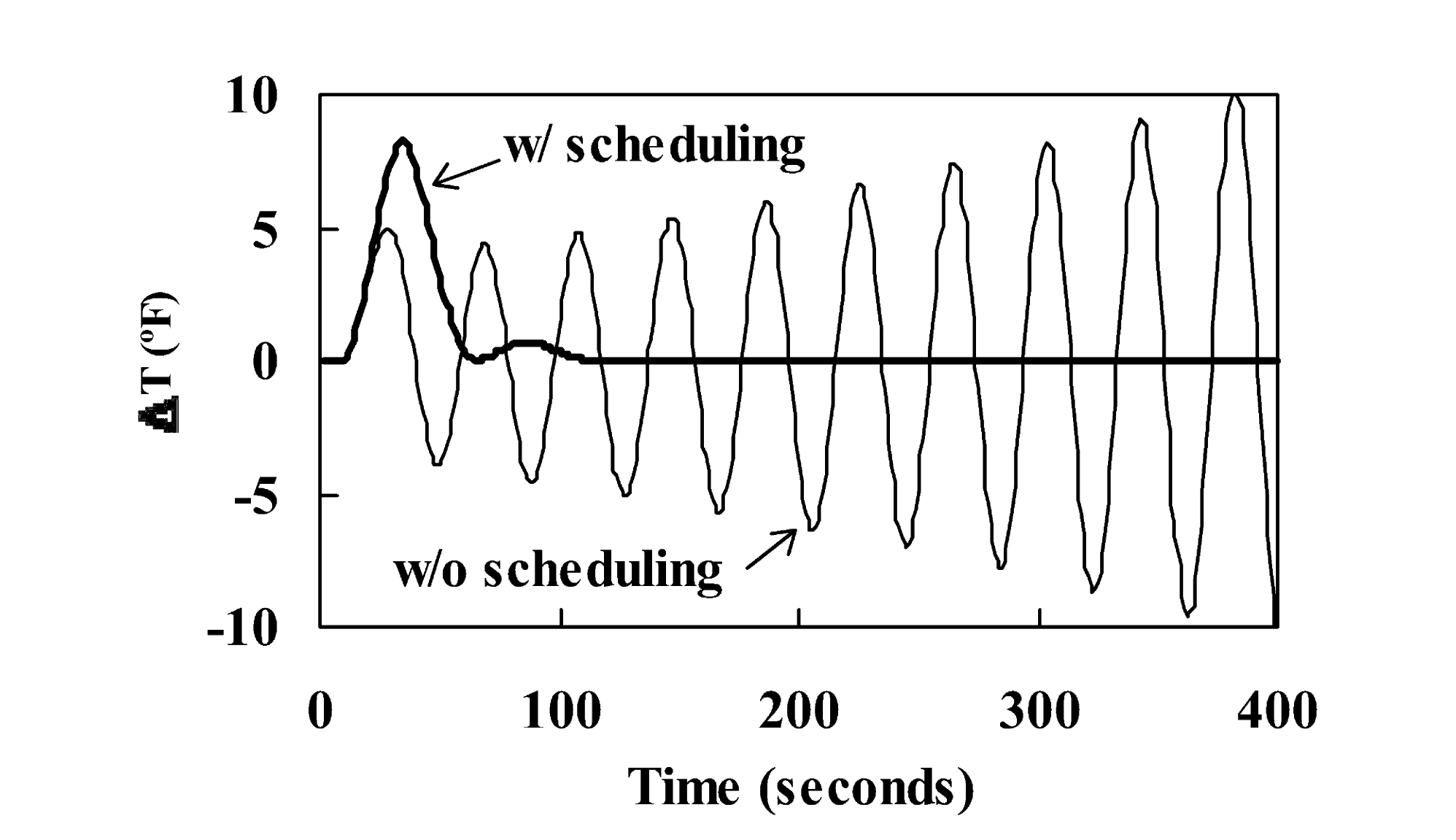

Effect of scheduling controller tuning

A nonscheduled controller that was tuned for v = 7 ft/sec after the feed rate is changed to v = 4 ft/sec and a scheduled controller for the same upset.

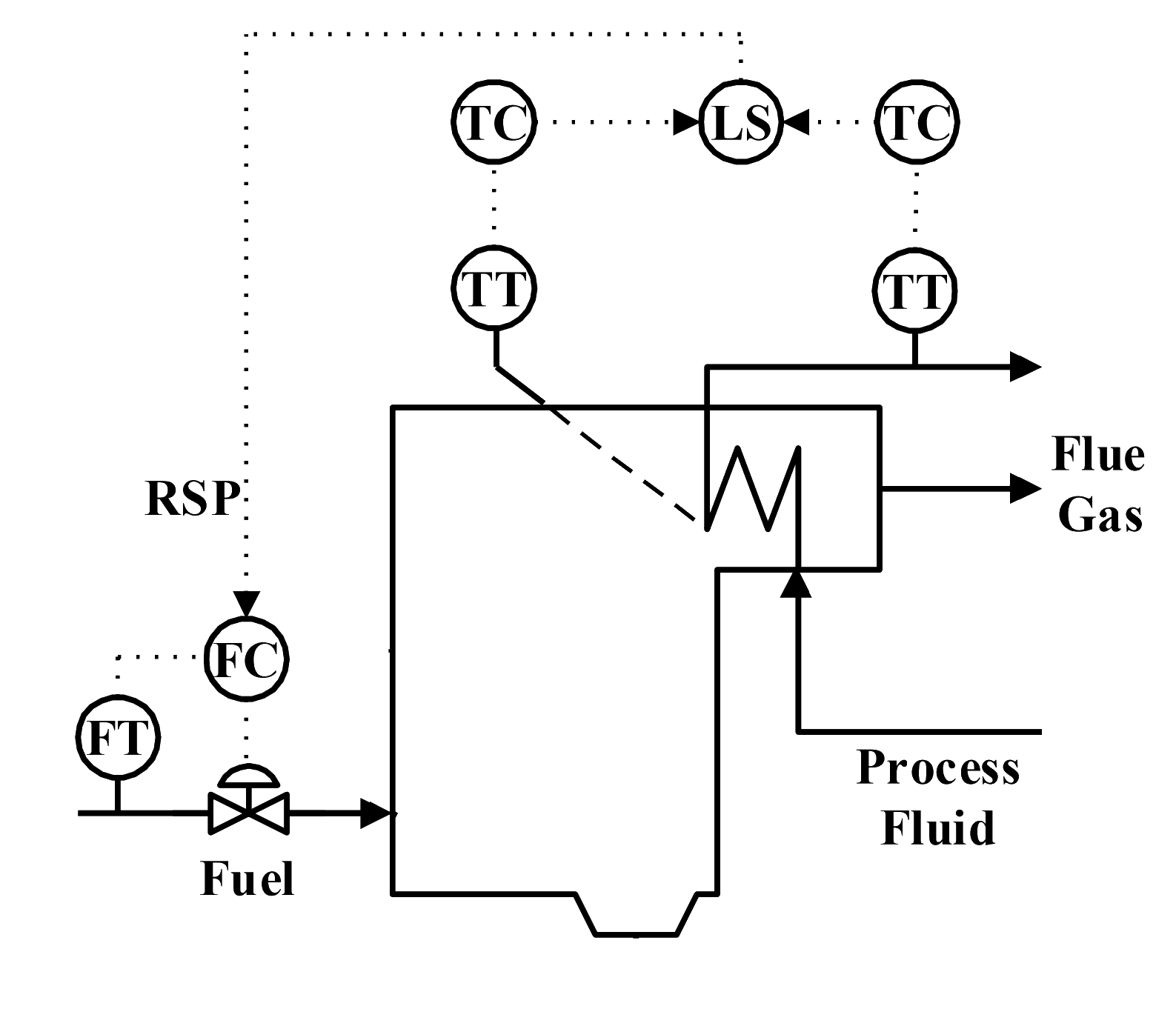

Override/select controls

Process are many times operated at the safety or equipment limits in order to maximize process throughput

During upset periods, it is essential that safety limits are enforced

Override/Select control uses LS and HS action to change which controller is applied to the manipulated variable.

Override/Select control uses selected action to switch between manipulated variables using the same control objective.

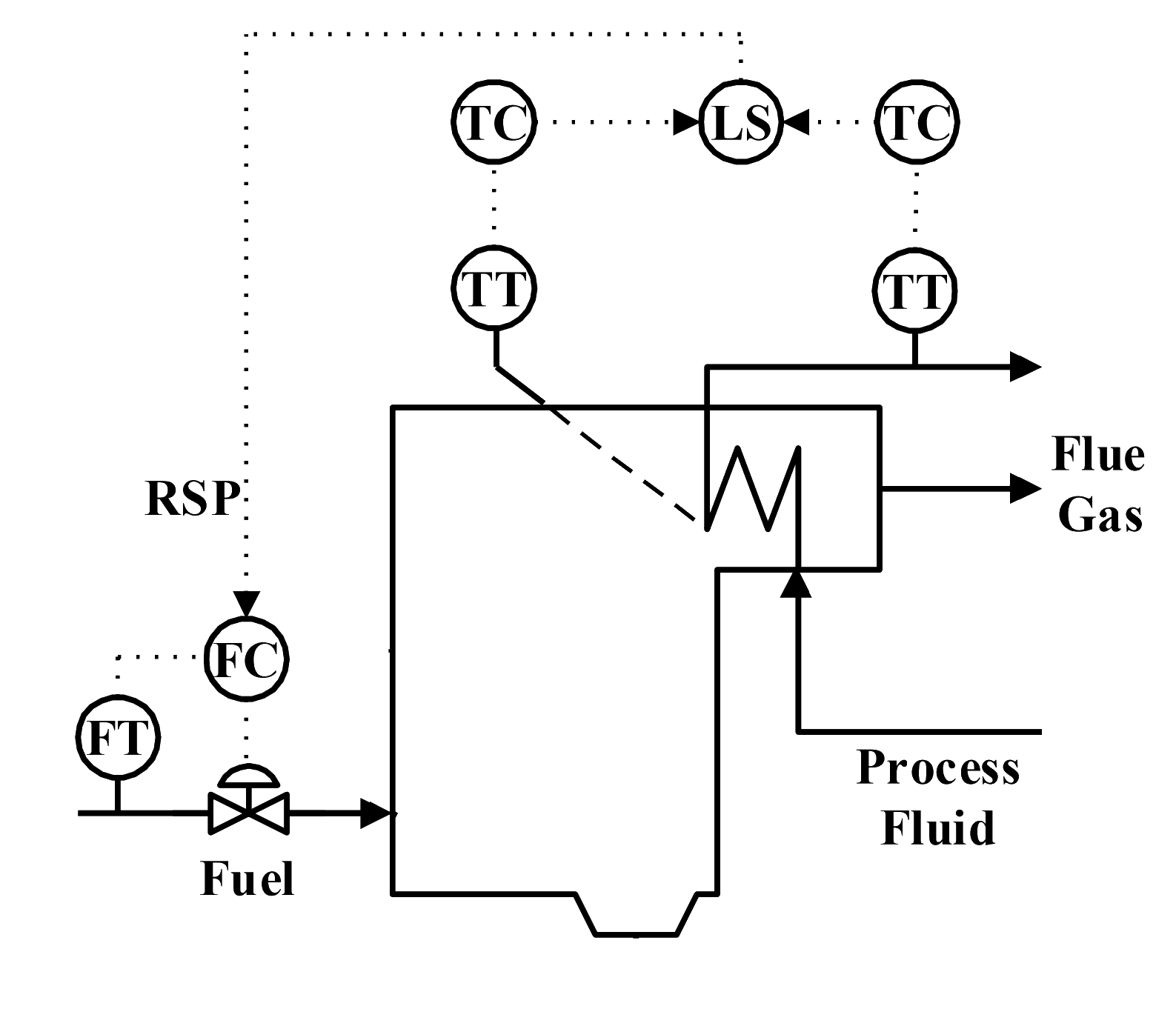

- Furnace tube temperature constraint control

- Two T controls: Tube T; Process fluid T

- 𝑄 = 𝐴𝑈 ∆𝑇

Increase Fp (process flow) will increase Q

∆𝑇 = 𝑇tube − 𝑇p

Tube temperature increase, it may violate maximum value, i.e. 500 C

Tube temperature constraint controller

- Under normal operation,

- Controller adjusts the furnace firing rate to maintain process stream at the setpoint temperature.

- Process fluid outlet temperature control is selected

- At higher feed rates

- Excessive tube temperatures can result in greatly reducing the useful life of the furnace tubes.

- Tube temperature control selected

- The LS controller reduces the firing rate to ensure that the furnace tubes are not damaged.

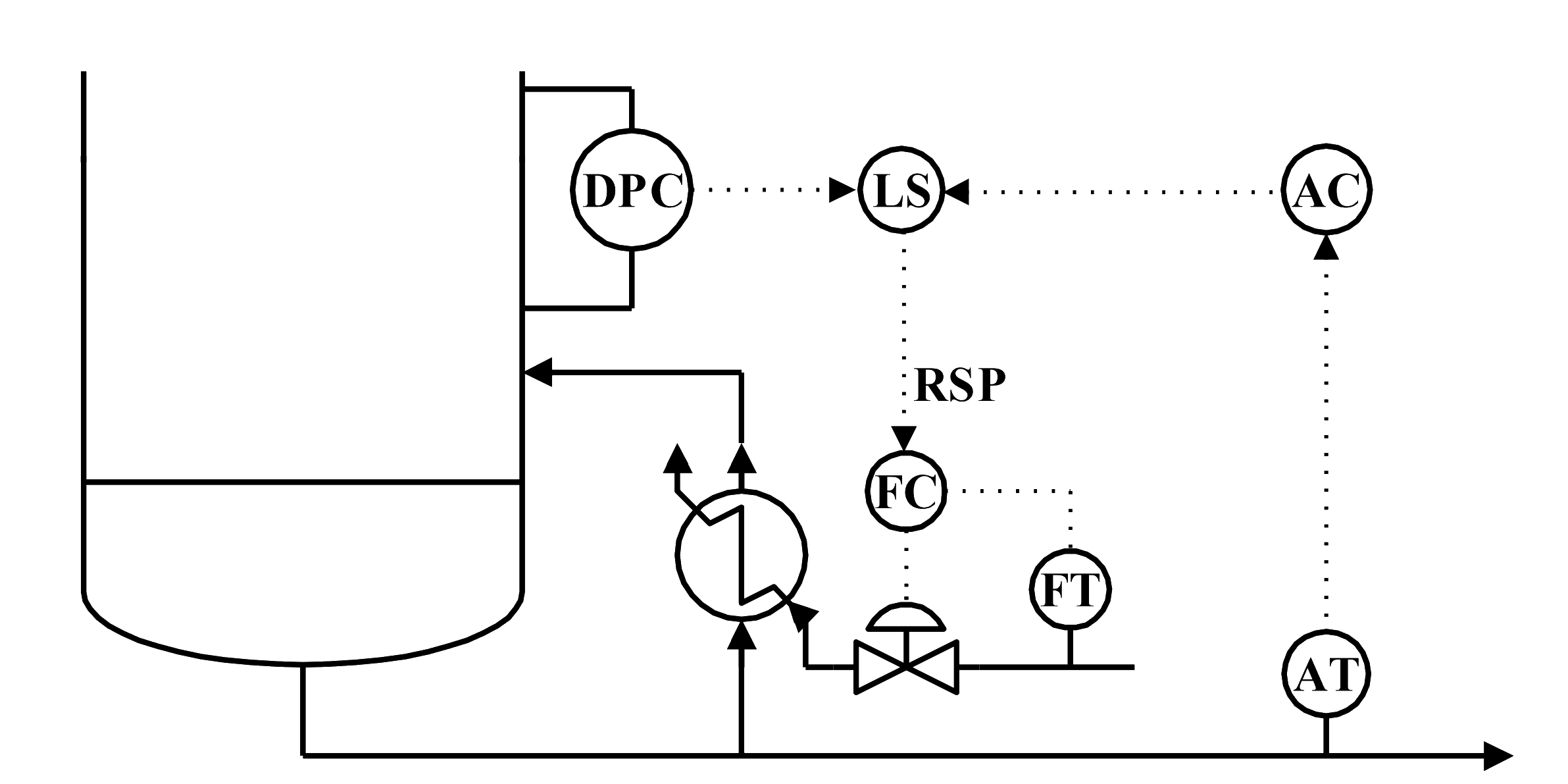

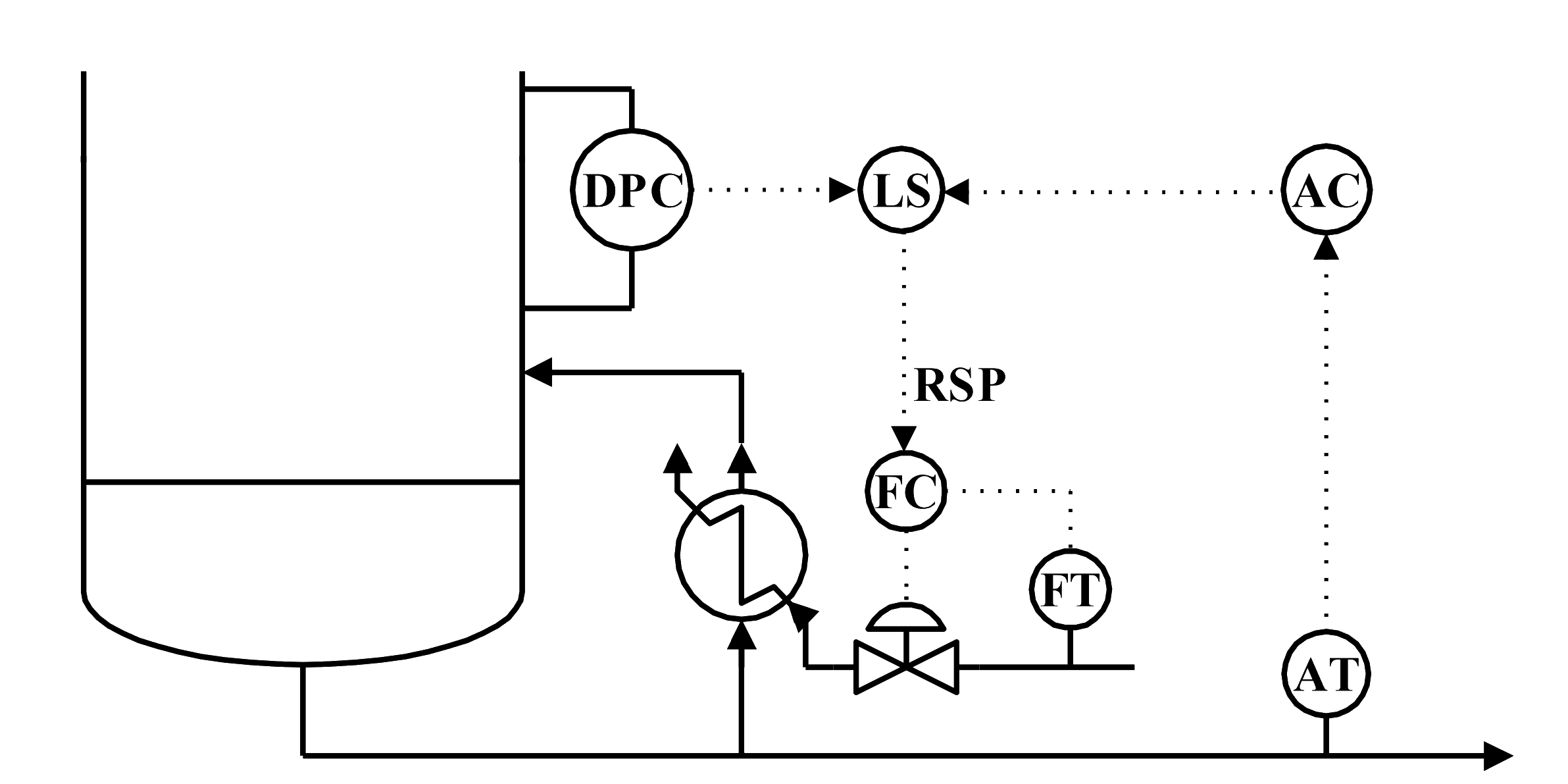

Column flooding constraint control

Controllers - AC: bottom purity; DPC: vapor flow

ΔP proportional to vapor flow. Higher ΔP means higher vapor flow across the trays. Too high vapor flow leads to column flooding – non smooth operation occur. To avoid flooding, implement DPC with LS controller.

Under abnormal situation, e.g., sudden increase in feed rate, more steam is required. This can dramatically increase the vapor flow leading to flooding. DPC will prevent this from happening

Analysis of override/select control – distillation column

- When pressure drop across the column reaches an upper operational limit

- Reboiler duty is switched from controlling; bottom product composition to maintaining operation at maximum pressure drop

- When the composition of the impurity in bottom product becomes less than setpoint (over purified),

- Reboiler duty is switched from controlling at maximum pressure drop to maintaining composition of bottom product

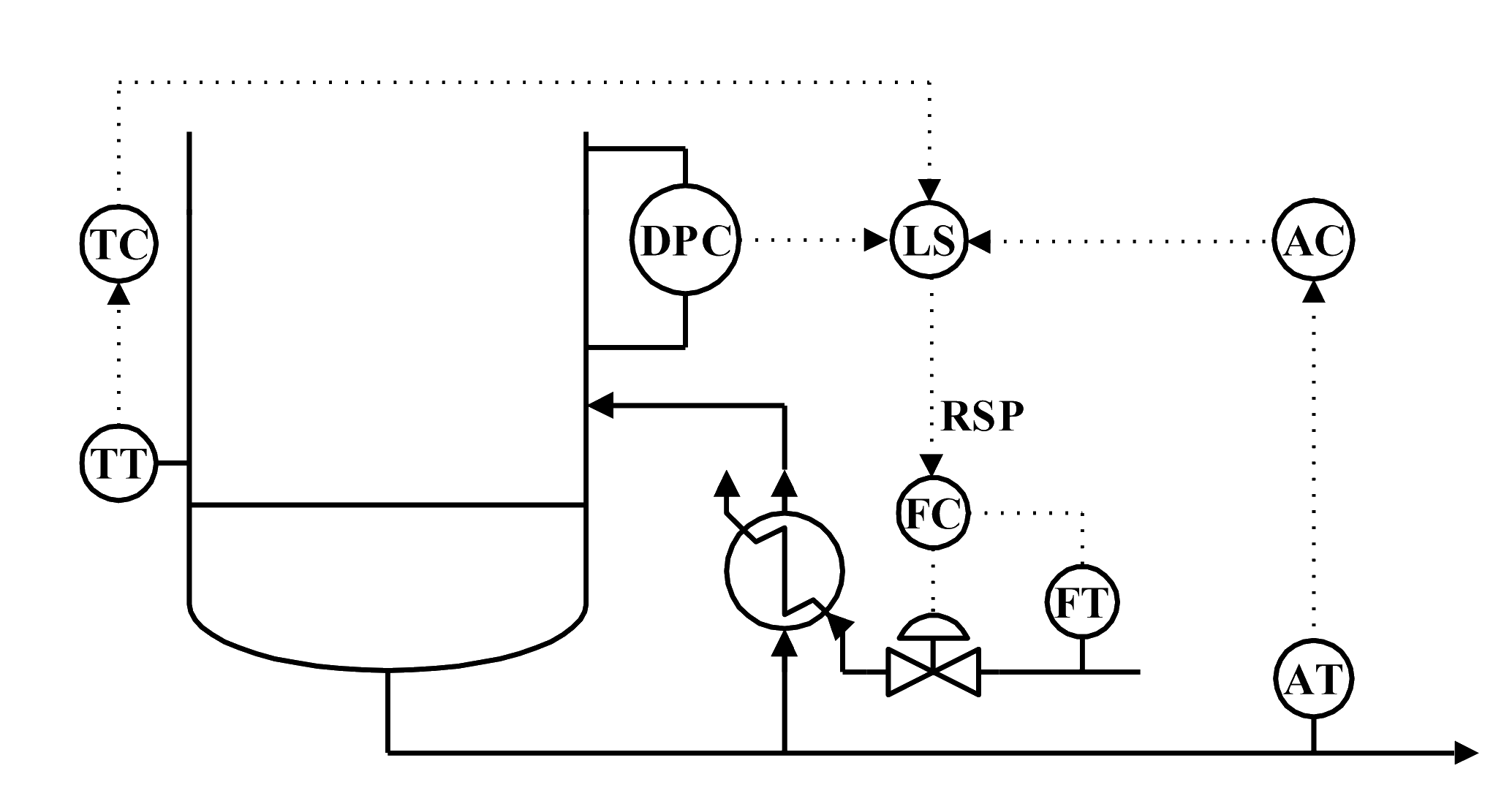

Controlling multiple constraints

Controllers - AC: bottom purity; TC: bottom temperature; DPC: vapor flow

DPC will be active if excessive vapor flow occurs under sudden increase in feed flow.

TC is used to protect the reboiler from excessively high temperature. Under abnormal situation, e.g., sudden drop in feed temperature, a lot of steam is required to maintain the bottom purity. This may lead to violation of maximum tube temperature. TC is used to prevent this from happening.

Hot spot temperature control

- Can be used to control the maximum temperature in a fixed-bed reactor

- Maximum reactor temperature occurs at different locations in the reactor

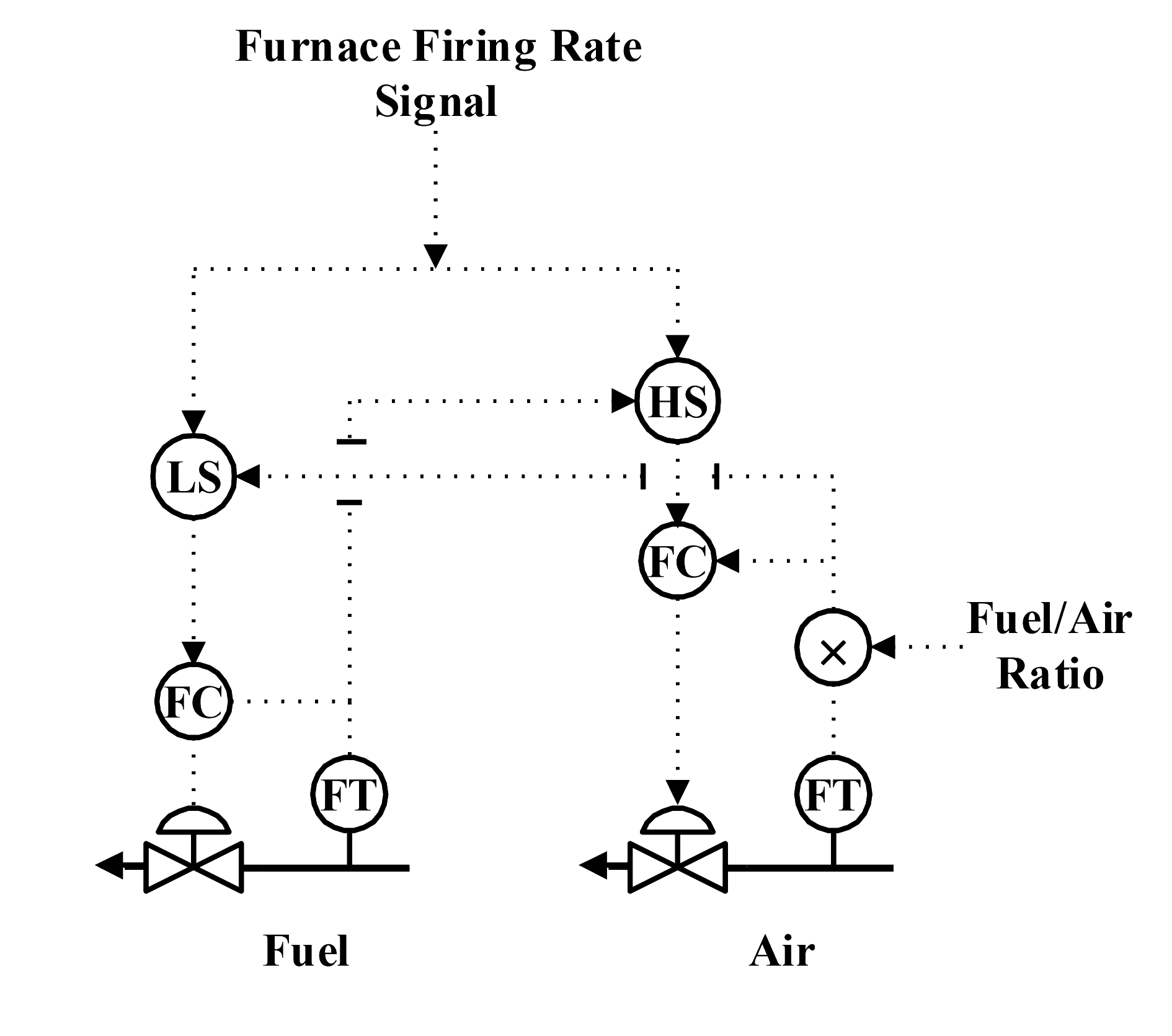

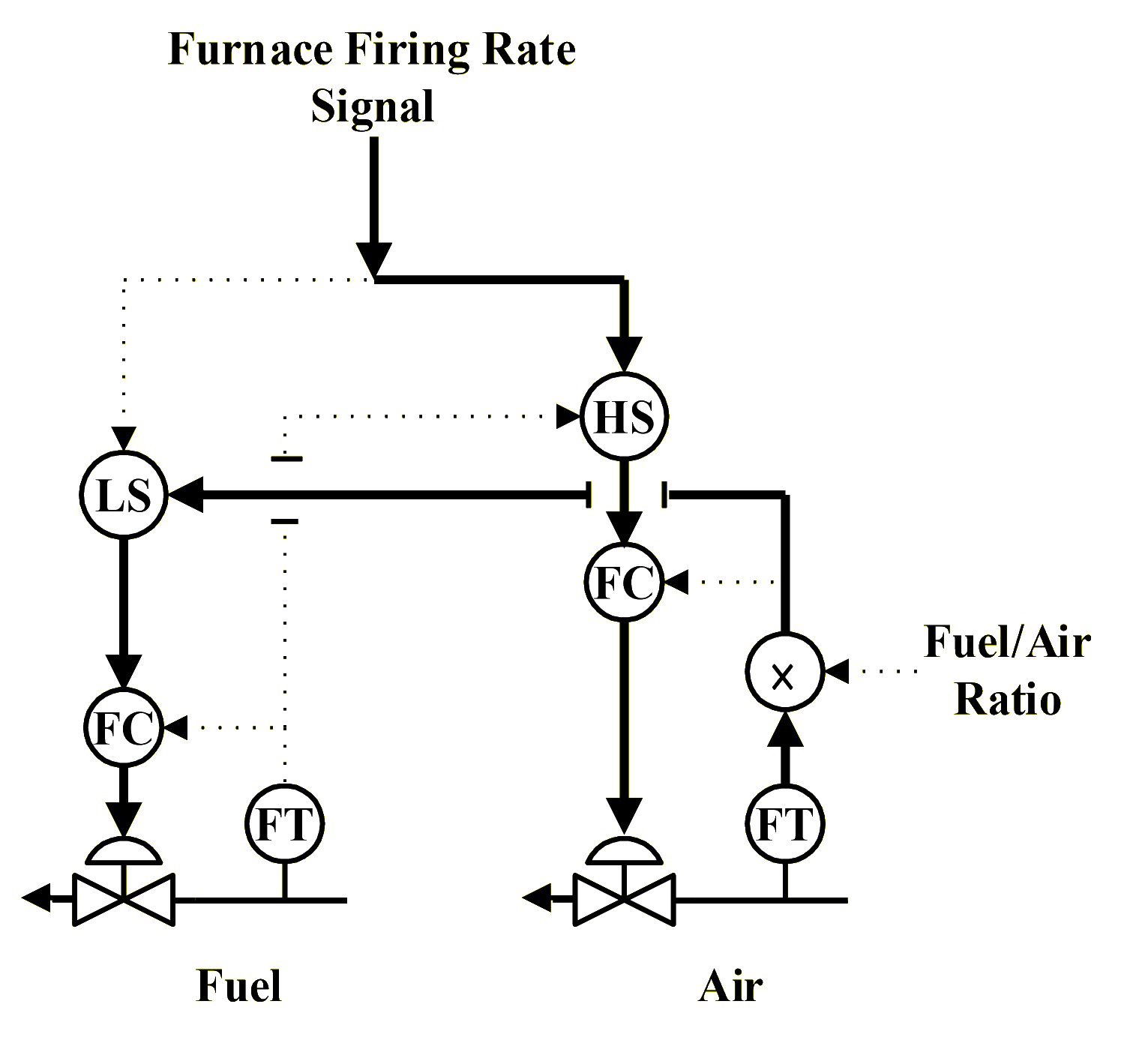

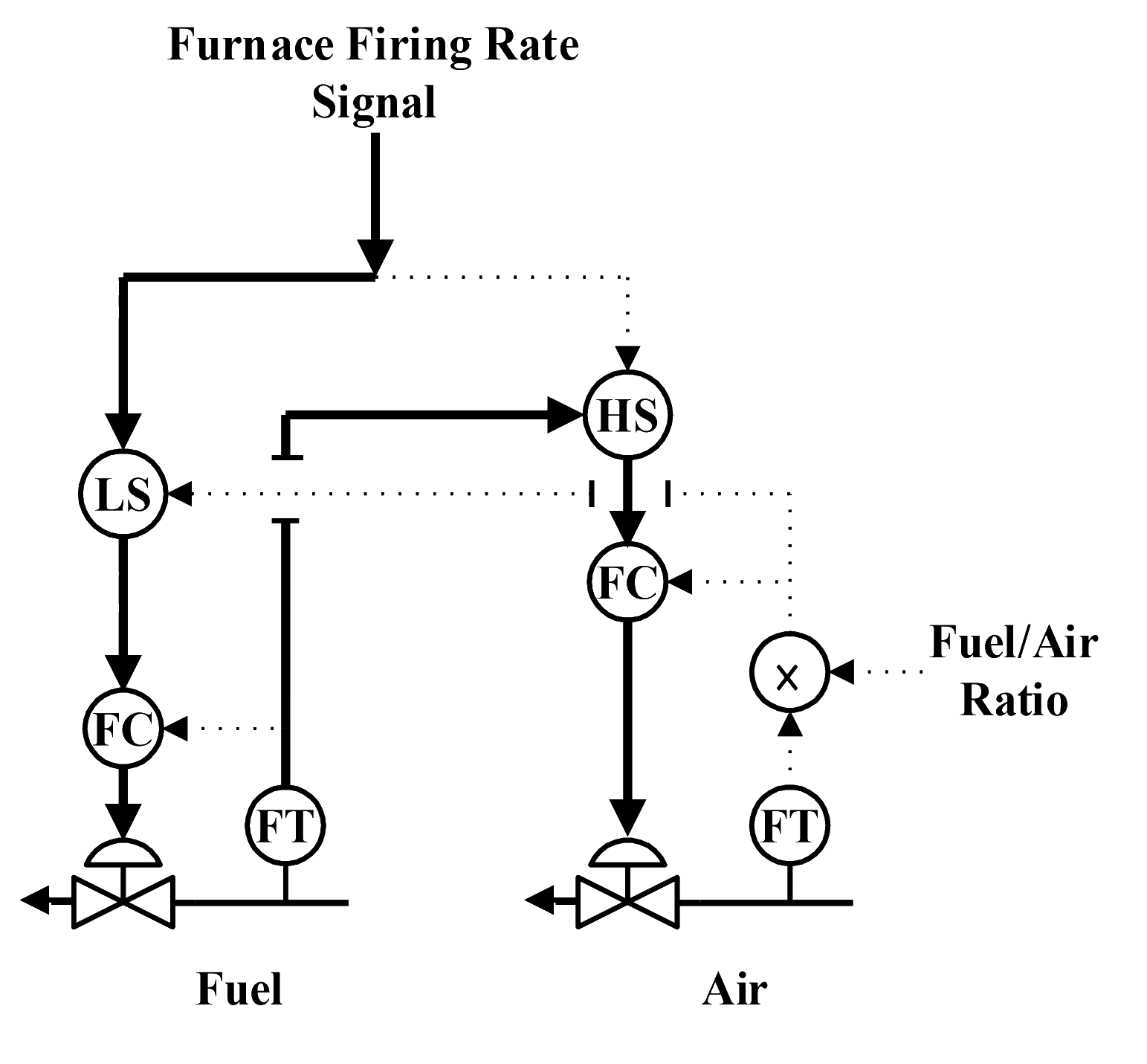

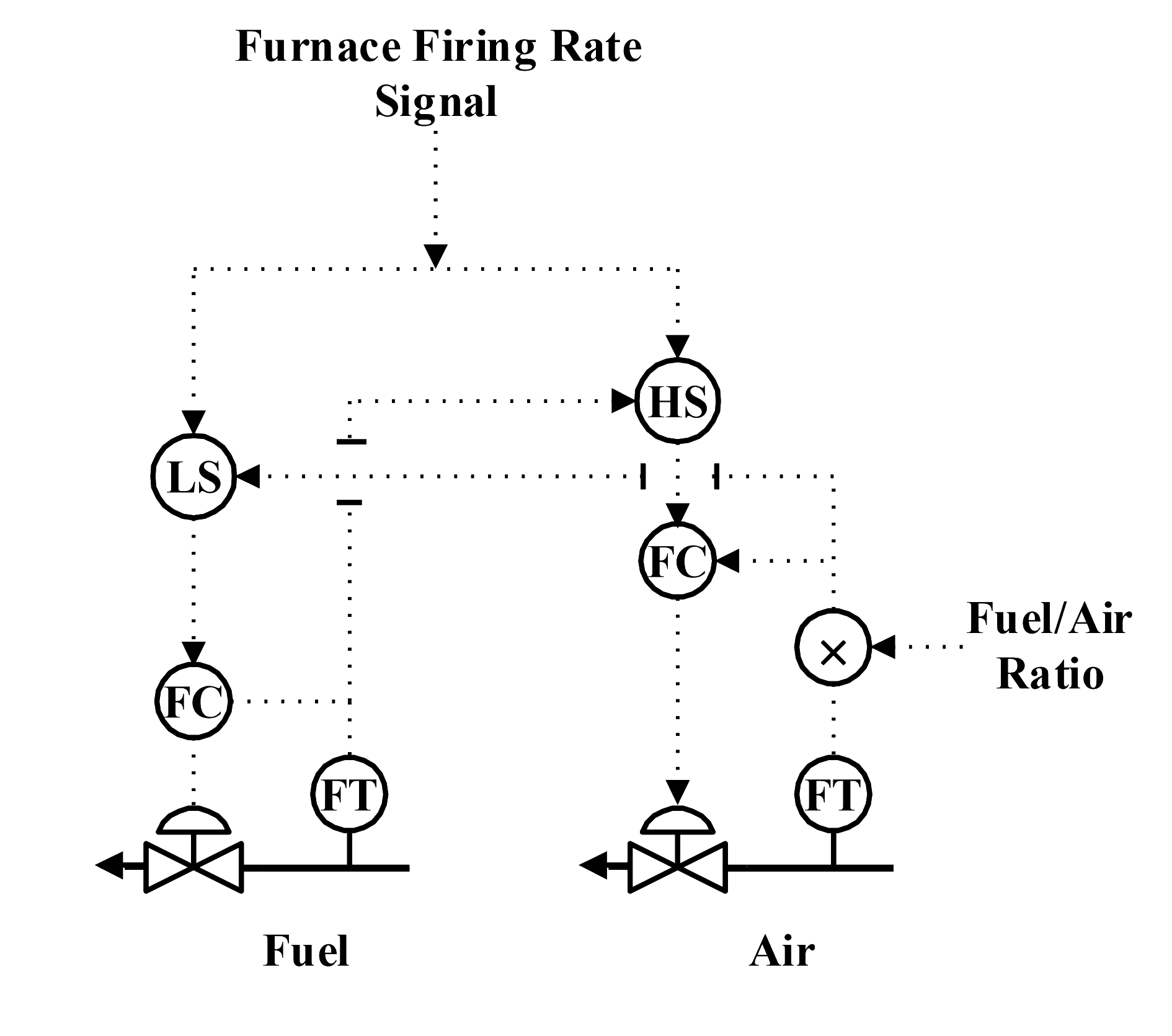

Cross-limiting firing controls

Firing rate increase

- HS ensures setpoint for air flow controller increases immediately.

- Then LS sends signal to fuel controller as its setpoint.

Firing rate decrease

- LS ensures setpoint for fuel controller decreases immediately.

- Then HS sends the signal to air flow controller as its setpoint.

Analysis of cross-limiting firing controls

It is critical that excess oxygen is maintained during firing rate increases or decreases or CO will form.

When the firing rate is increased, the air flow rate will lead the fuel flow rate.

When the firing rate is decreased, the fuel flow rate will lead the air flow rate.

Air flow rate controller is based on equivalent fuel flow rate (fuel/air ratio).

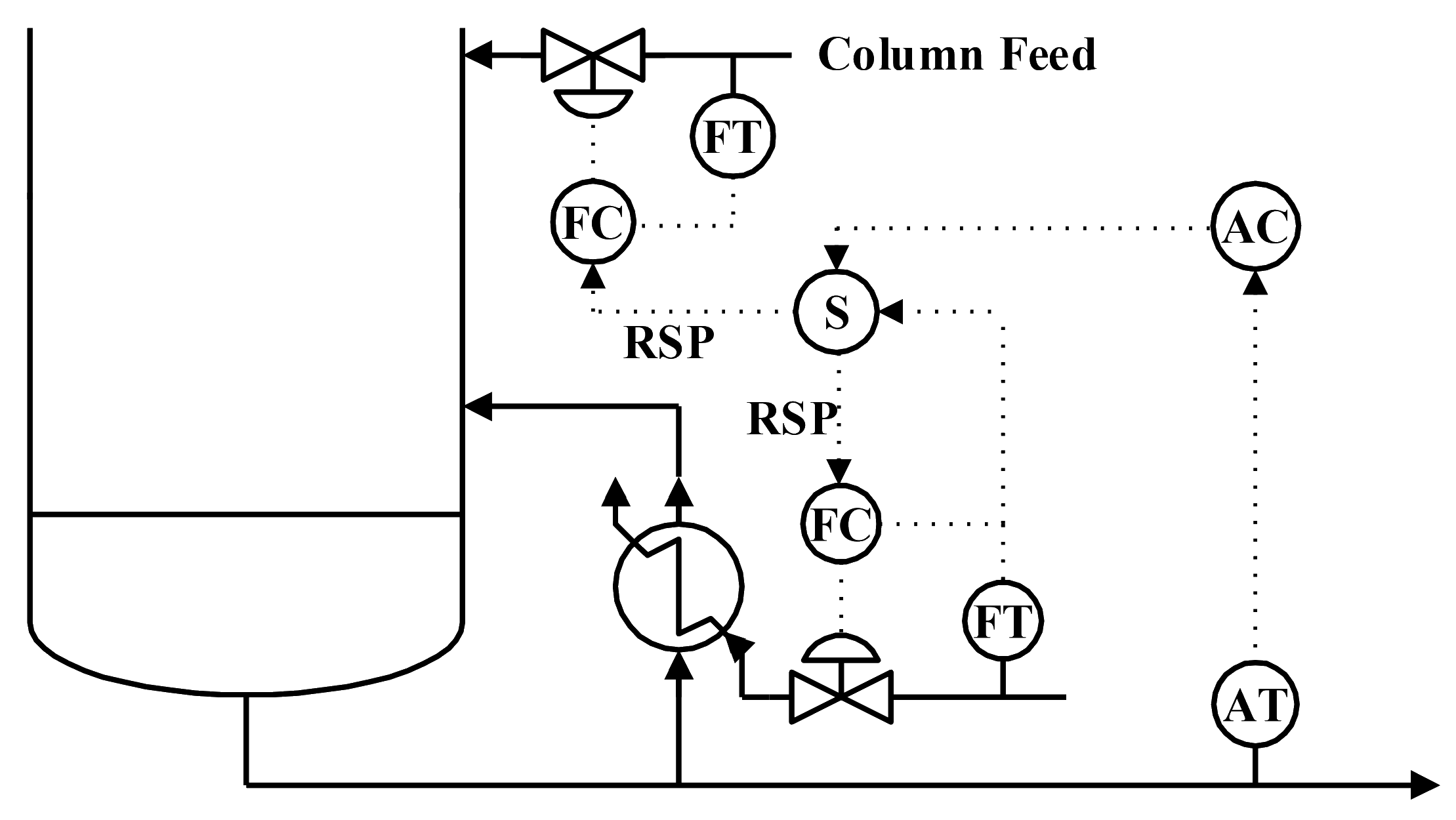

Override control

- Select control to maintain bottom product purity when a maximum reboiler constraint is encountered.

- S selects the most critical stream in a cascade control loop.

Summary

- Ensuring safe, smooth and profitable operation requires adequate control system in place.

- Where applicable, inferential control reduces deadtime at a very effective price.

- When process nonlinearity is serious, consider the scheduling controller tuning.

- Use override/select controls to satisfy safety and operational constraints.

- Control system must be able to deal with multiple constraints to ensure safe, smooth and profitable operation.

Advanced Modeling and Control