Recap: Basics of Process Control and Modelling

Advanced Modeling and Control

Why process control

- Importance of process analysis and control

- Process control objectives

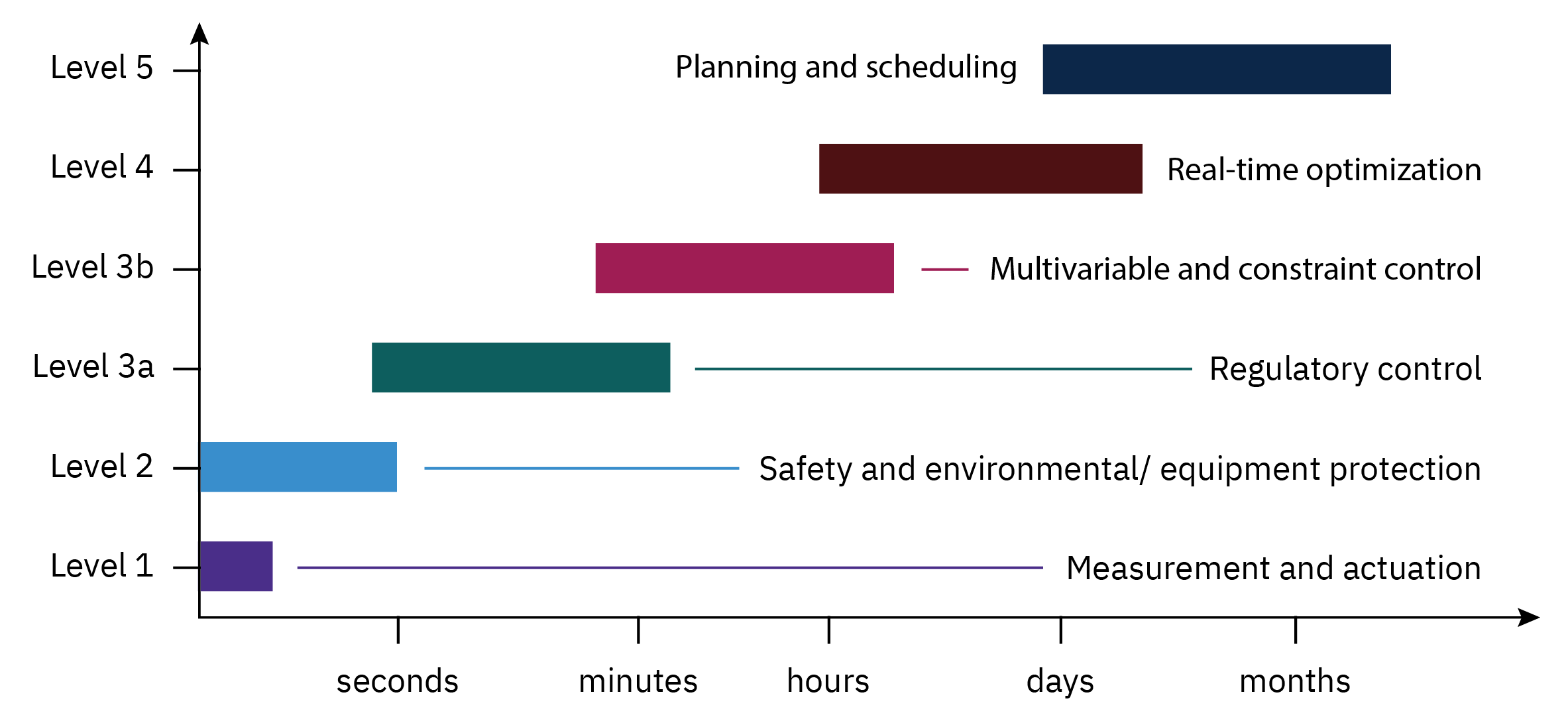

- Hirarchy of process control activities

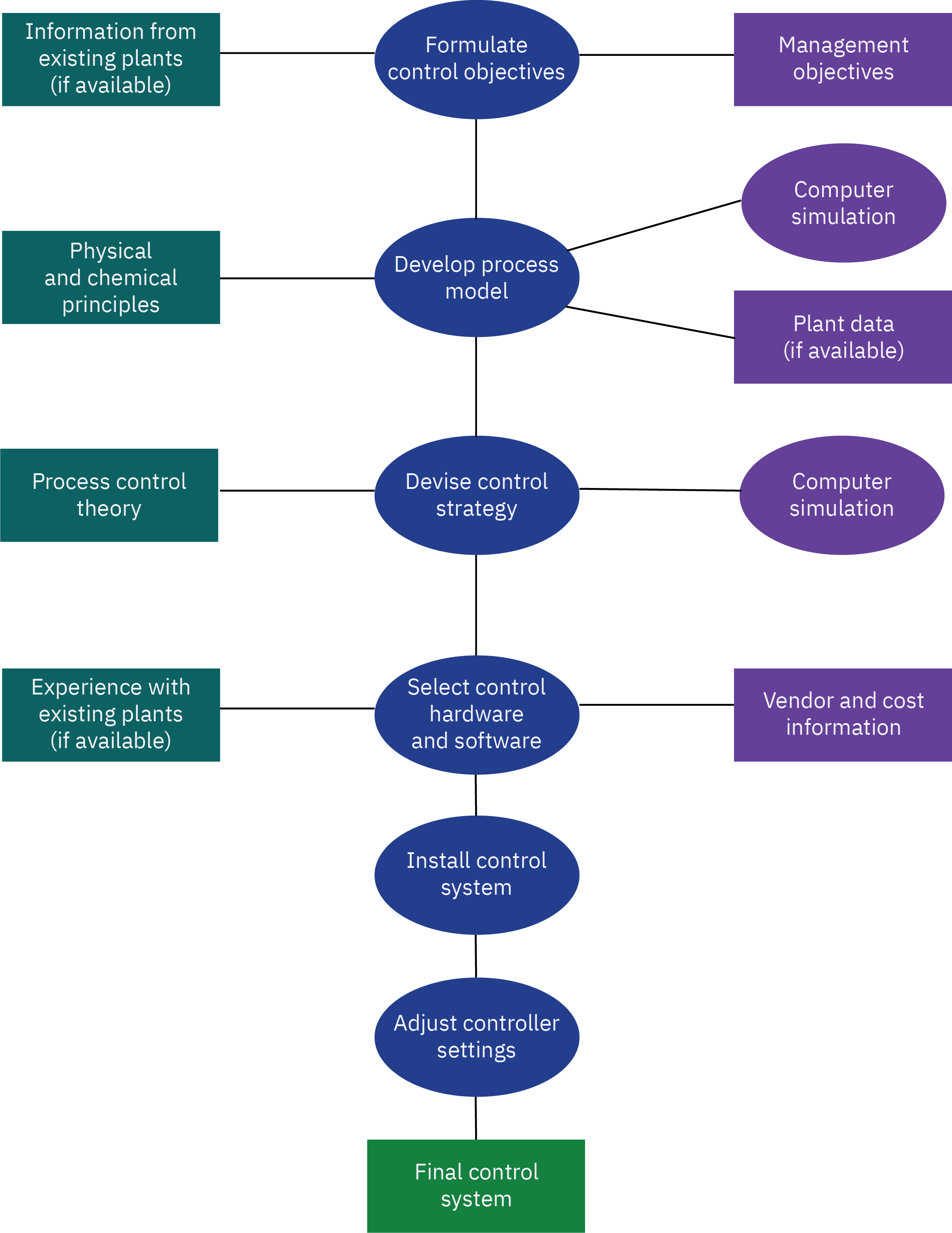

- Overview of control system design

Importance of process analysis and control

- Optimal process operations require efficient and effective control

- Control systems and advanced algorithms are deployed to monitor, regulate, and optimize the process variables.

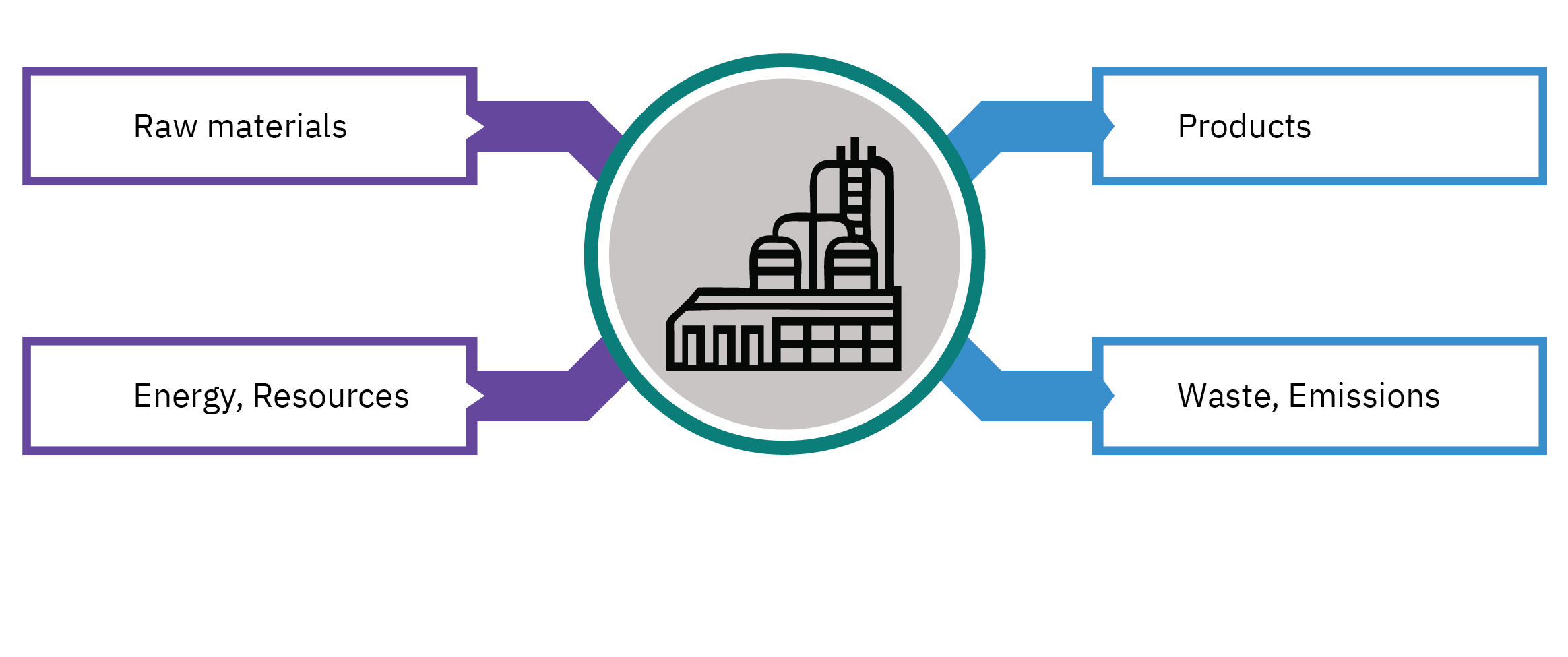

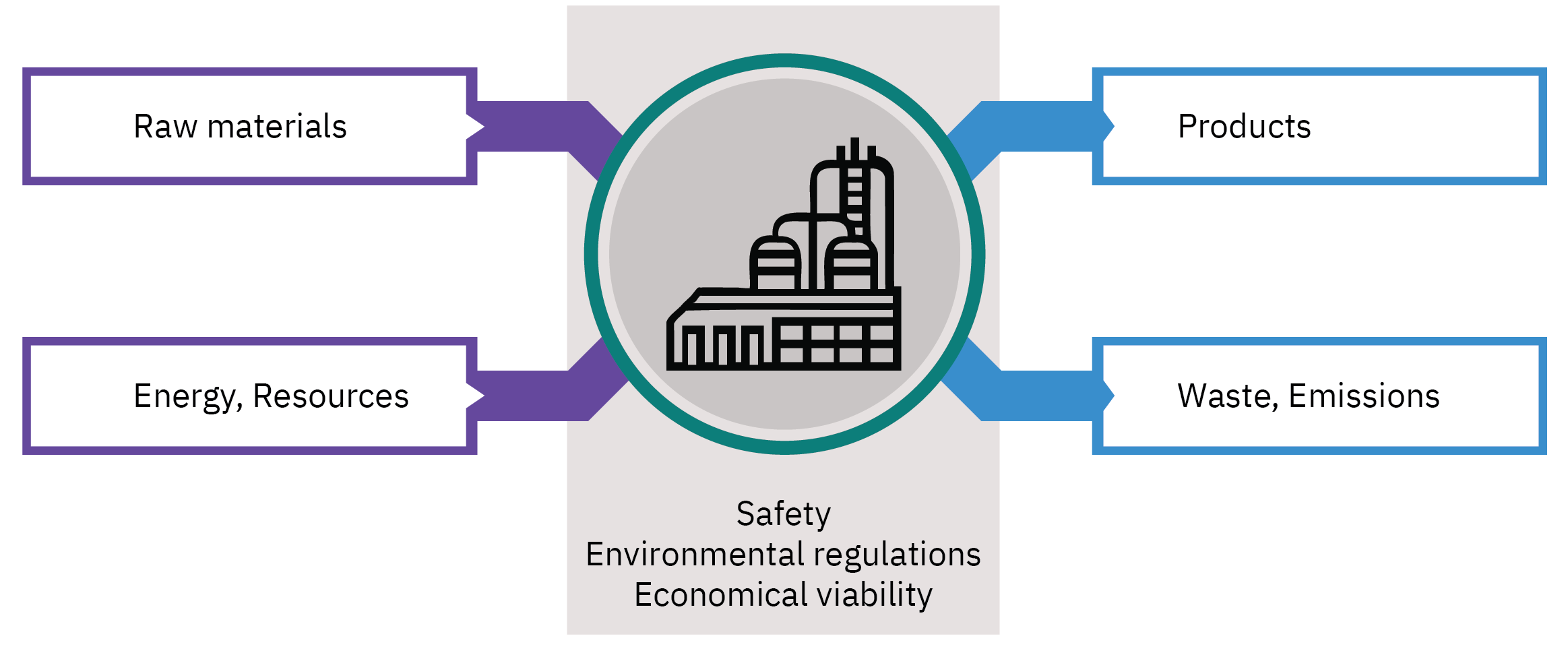

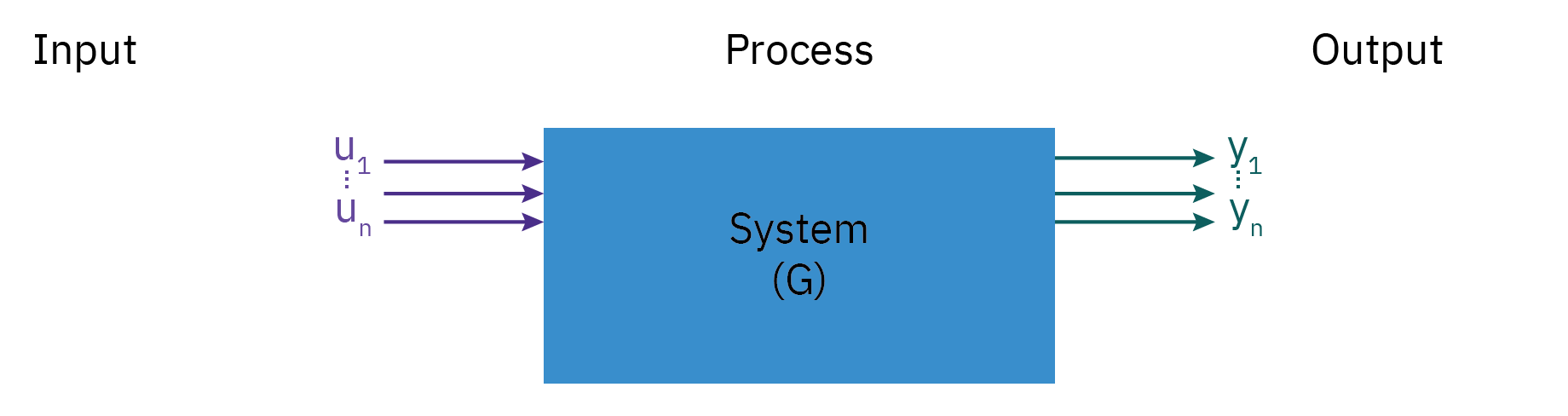

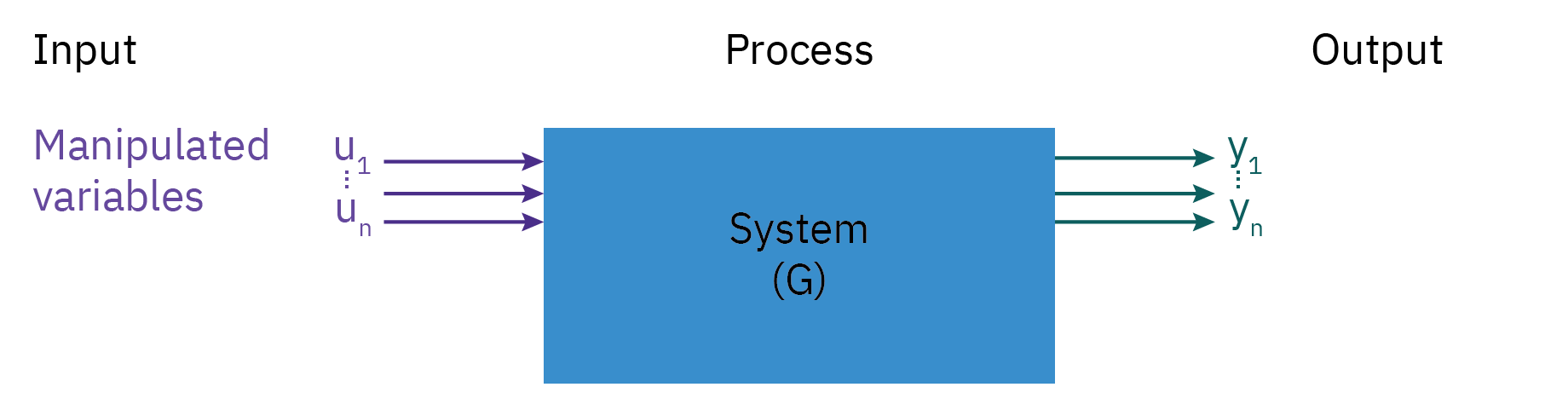

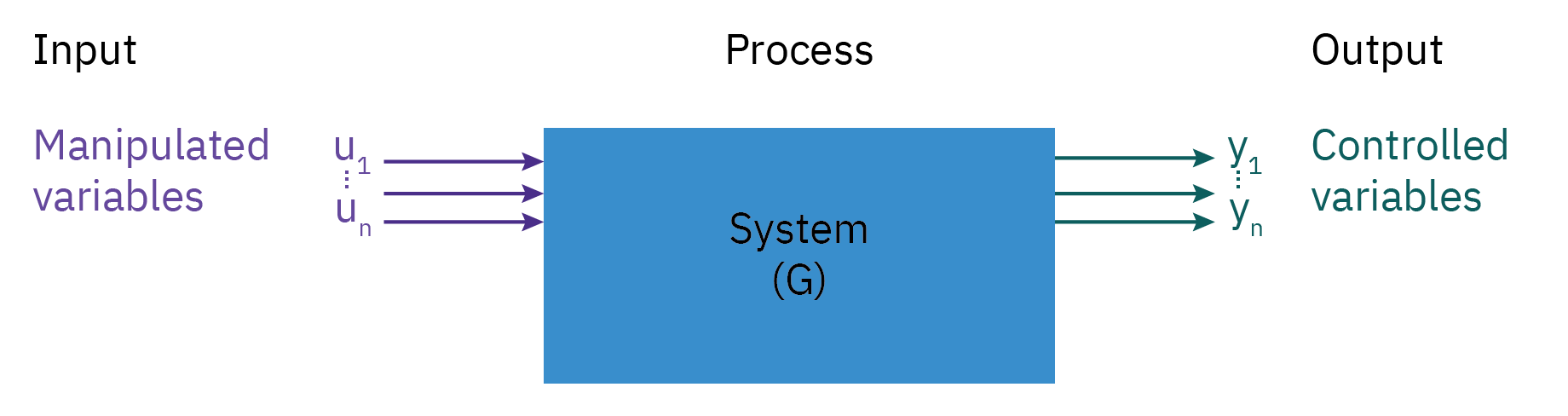

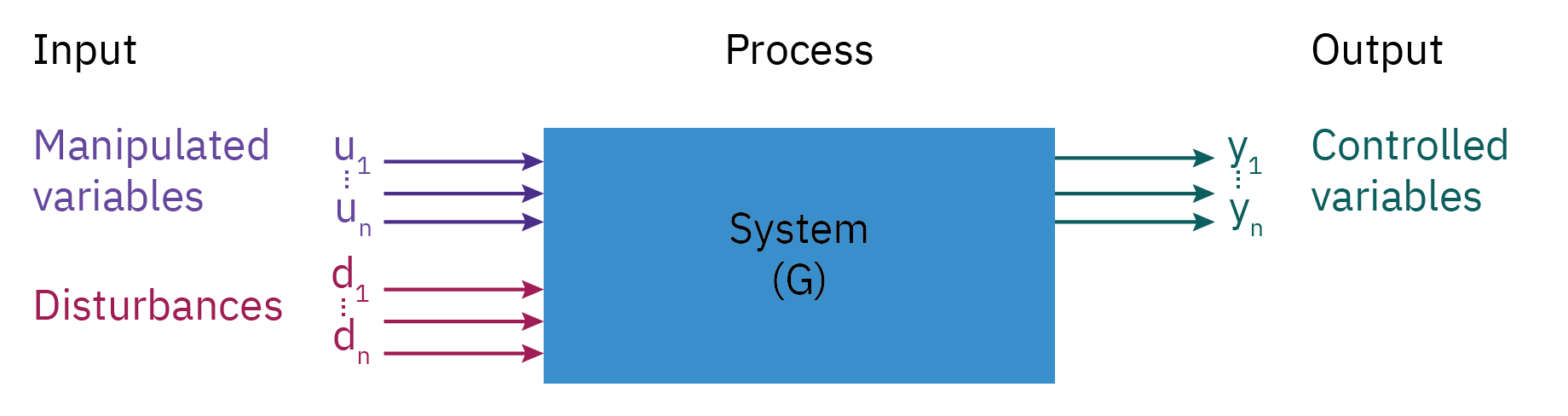

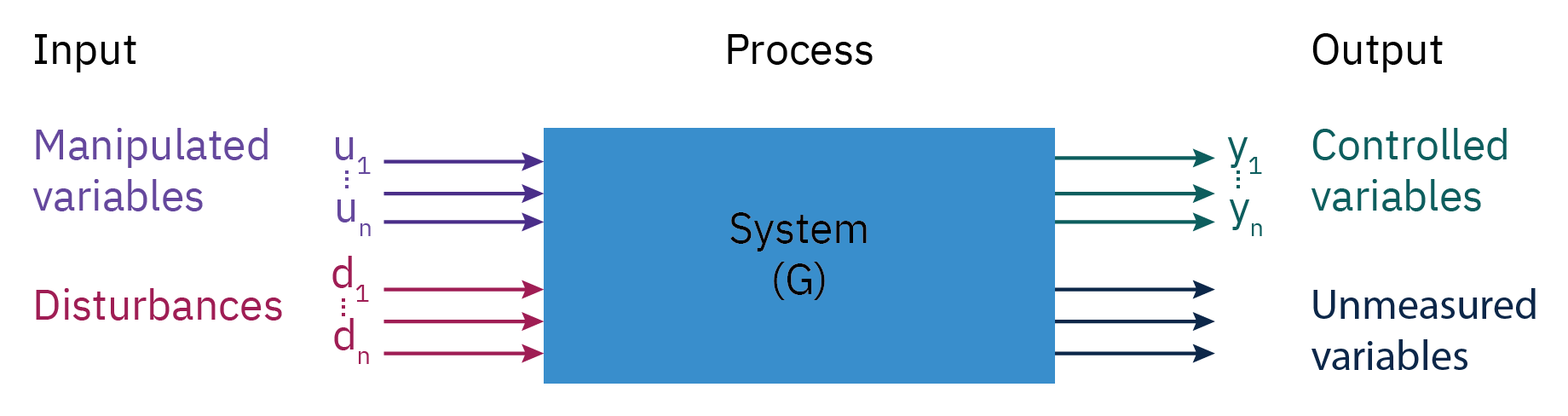

Process System, Input and Output

Manipulated Variable (MV): The flow rate of the liquid into or out of the tank.

Controlled Variable (CV): Level of the liquid in the tank

Disturbances: Changes in inlet flow rate, changes in outlet flow rate, temperature variations, pressure fluctuations

Unmeasured Output: The temperature of the liquid in the tank

Control objectives

Explicit control objectives (ECOs)

Clearly defined and typically quantifiable goals for the performance of a control system.

These objectives are explicitly stated

Form the basis of the formal design and analysis of control systems

Examples:

Setpoint Tracking, Disturbance Rejection, Stability, Speed of Response, Overshoot Minimization, Regulatory Compliance

Implicit control objectives (ICOs)

Not explicitly stated or quantified

Often evaluated qualitatively

Have a significant long-term impact

Play a crucial role in the successful implementation

Examples:

Simplicity, Reliability, Cost-effectiveness, Safety, Flexibility, Scalability

Control System Design should link the two types of control objectives.

Real plants can have similar ICOs but different ECOs

Implicit control objectives

Safety First

- People

- Environment

- Equipment

Profit

- meeting final product specifications

- minimizing waste production

- minimizing environmental impact

- minimizing energy use

- maximizing overall production rate

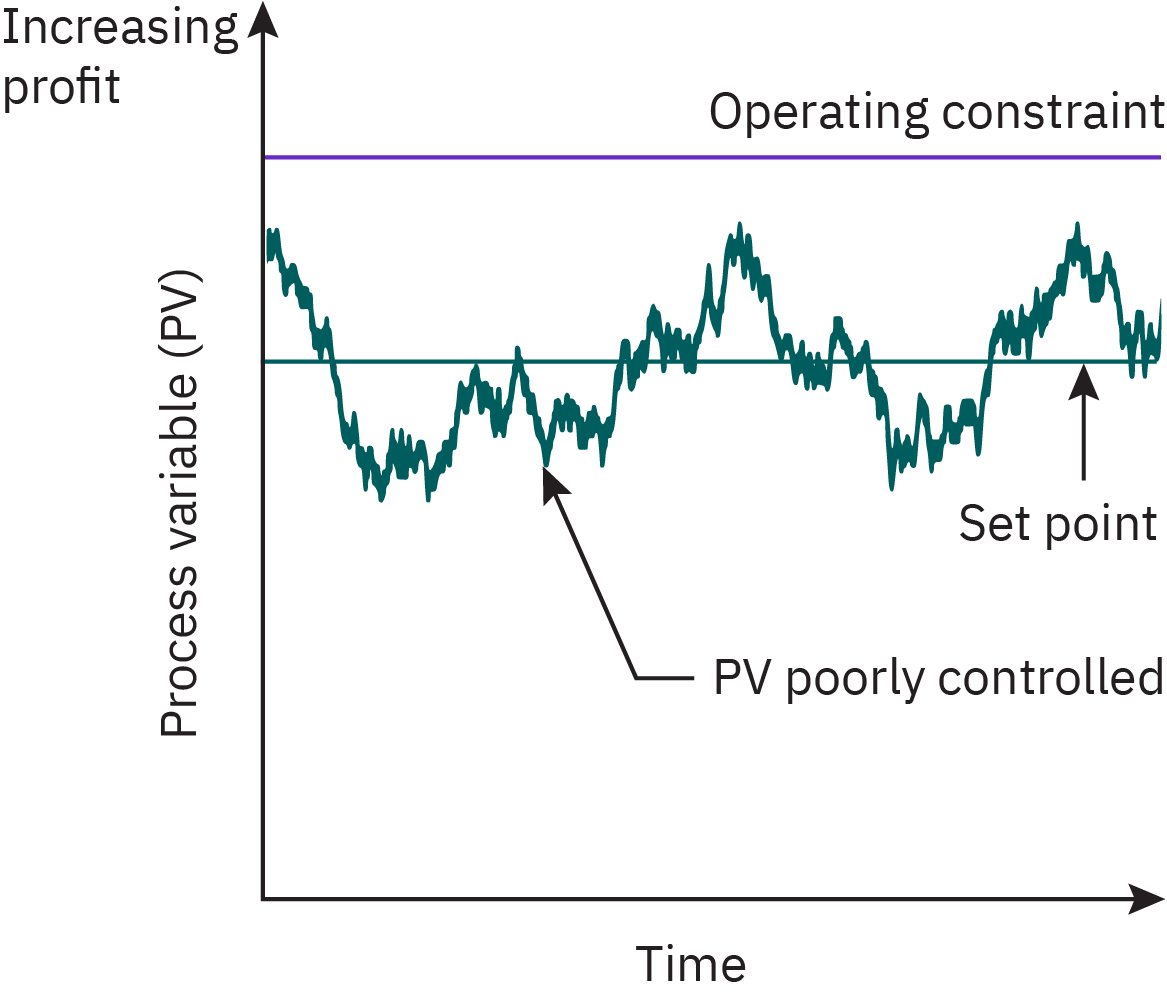

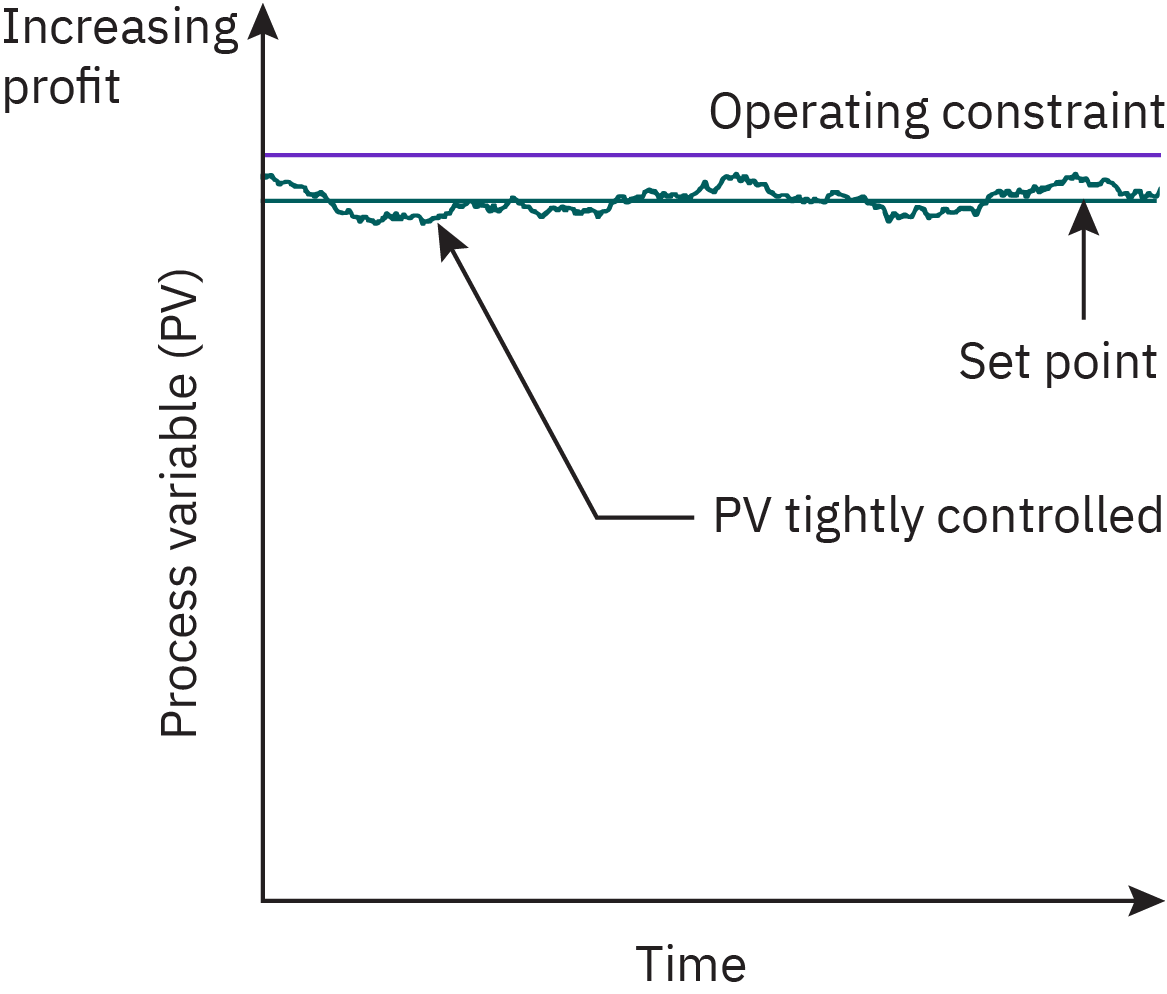

Reducing variability

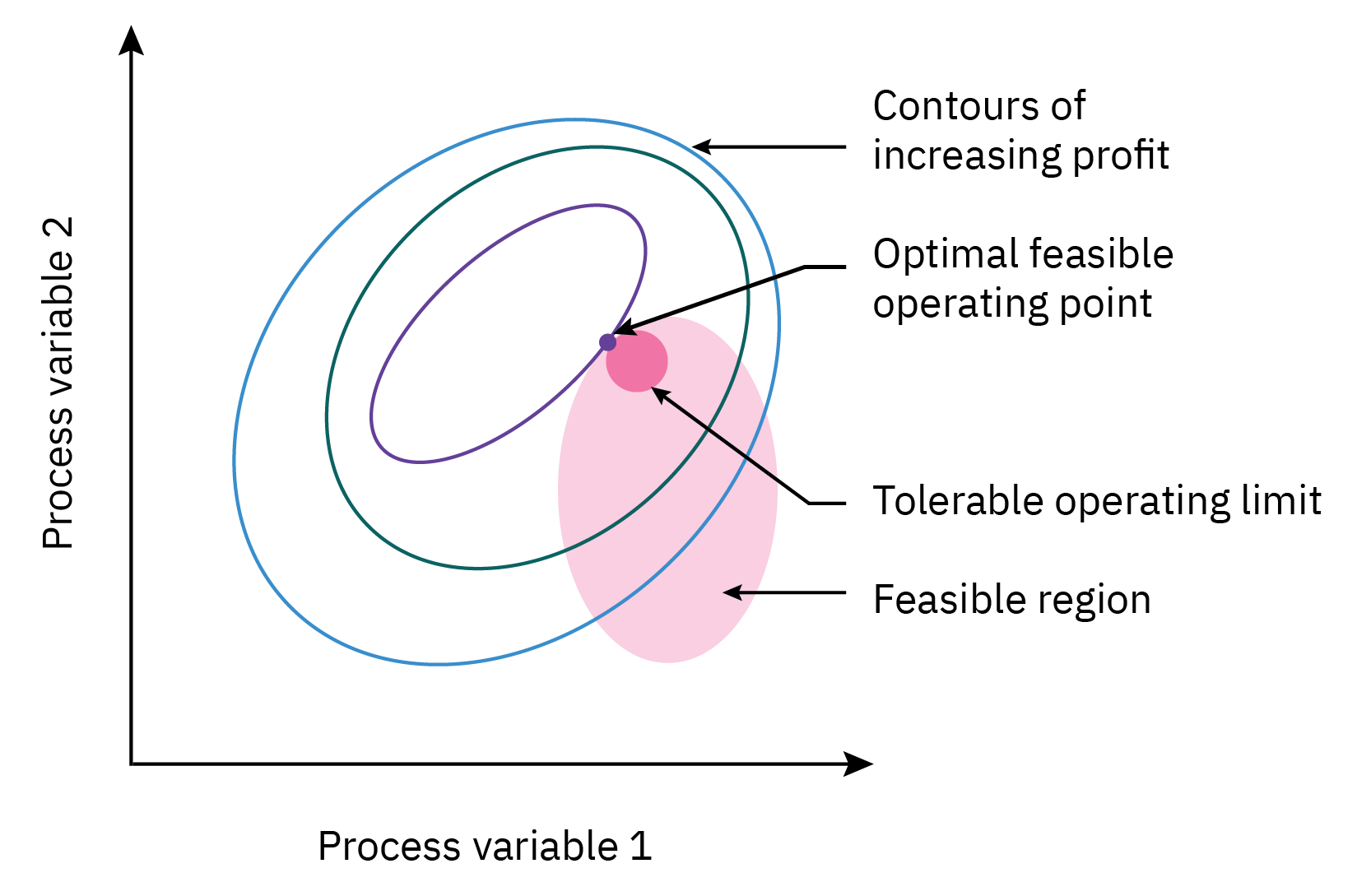

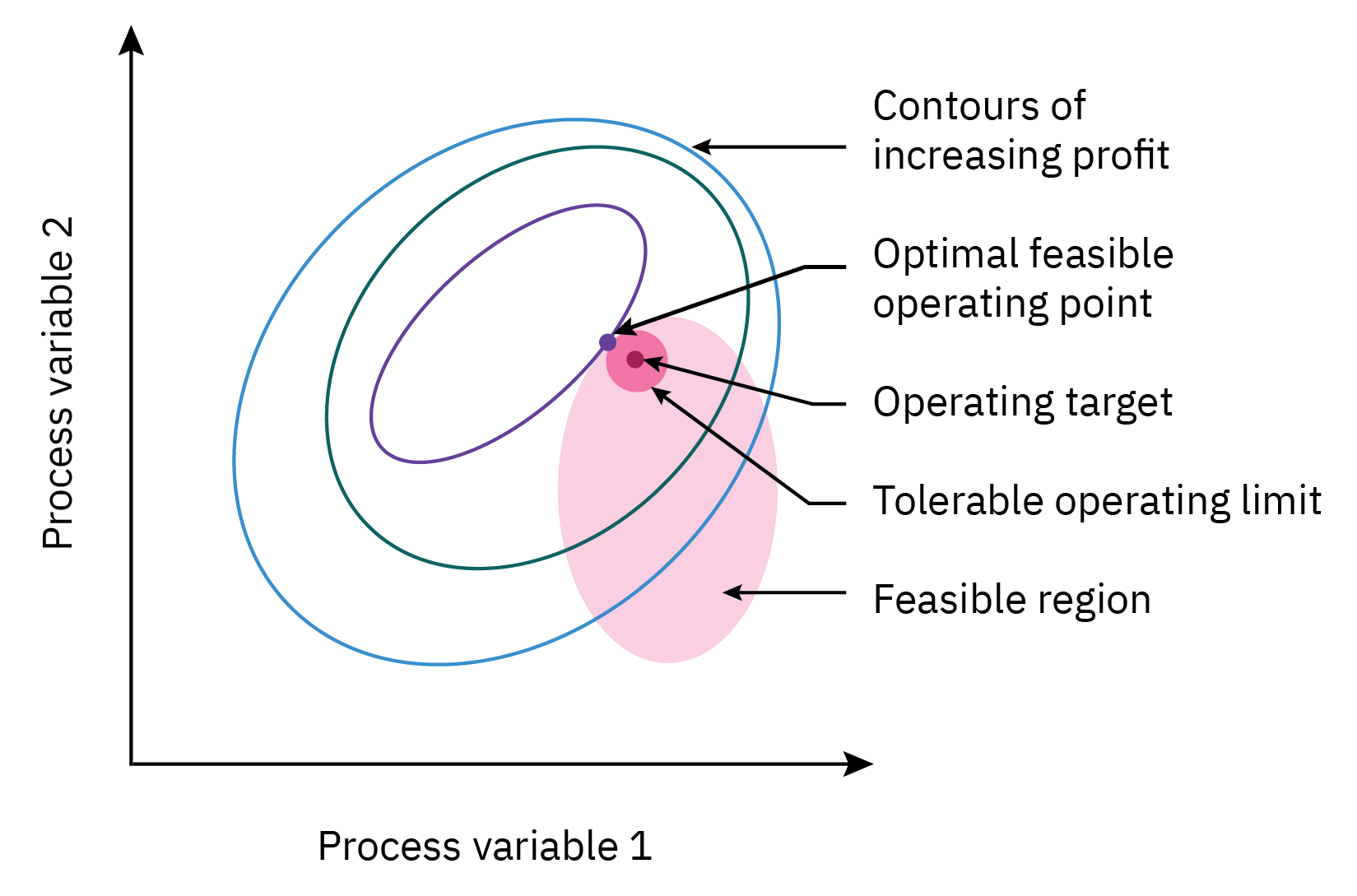

Poor control requires set point far from constraint

Good control permits set point near constraint

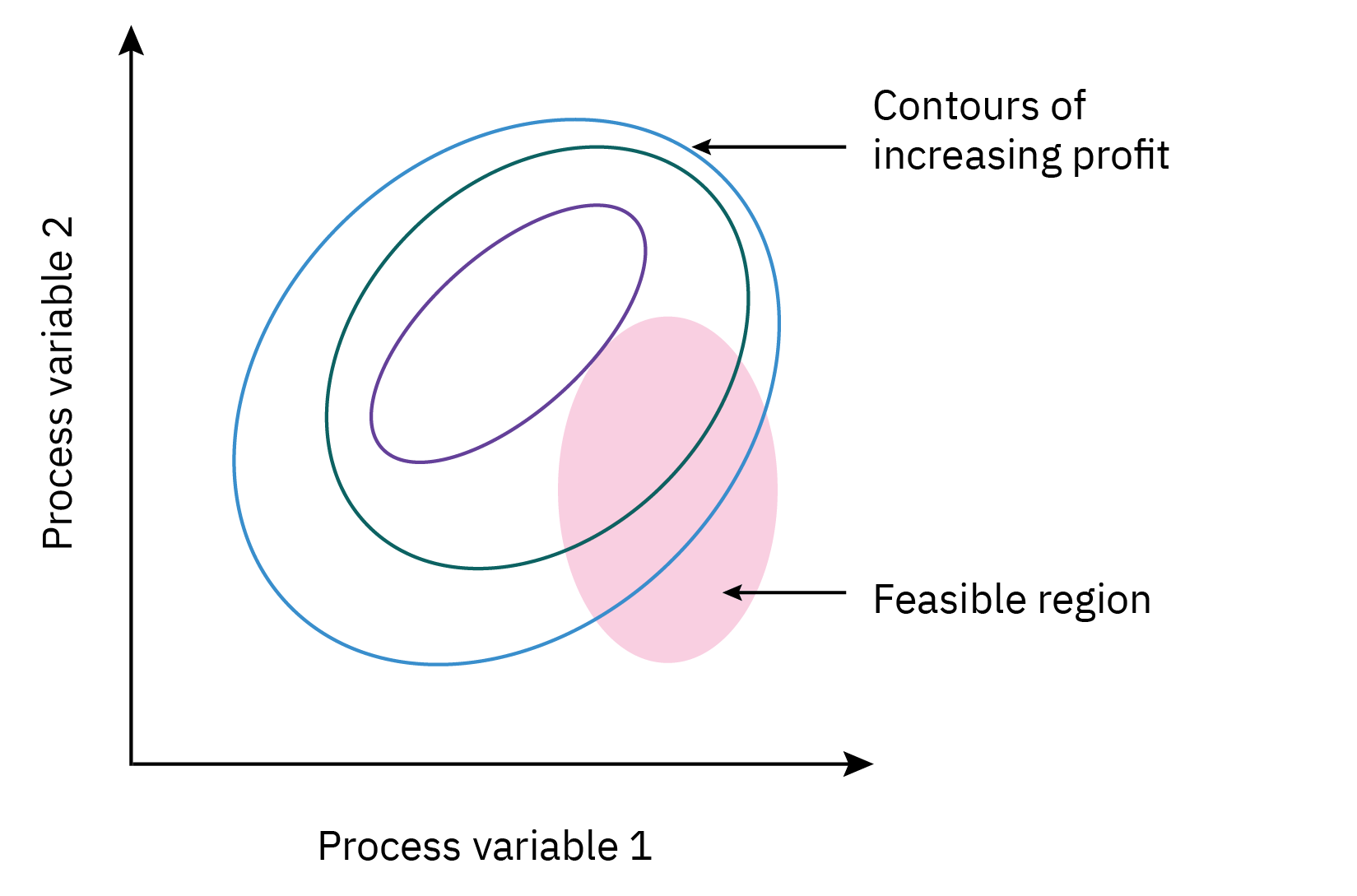

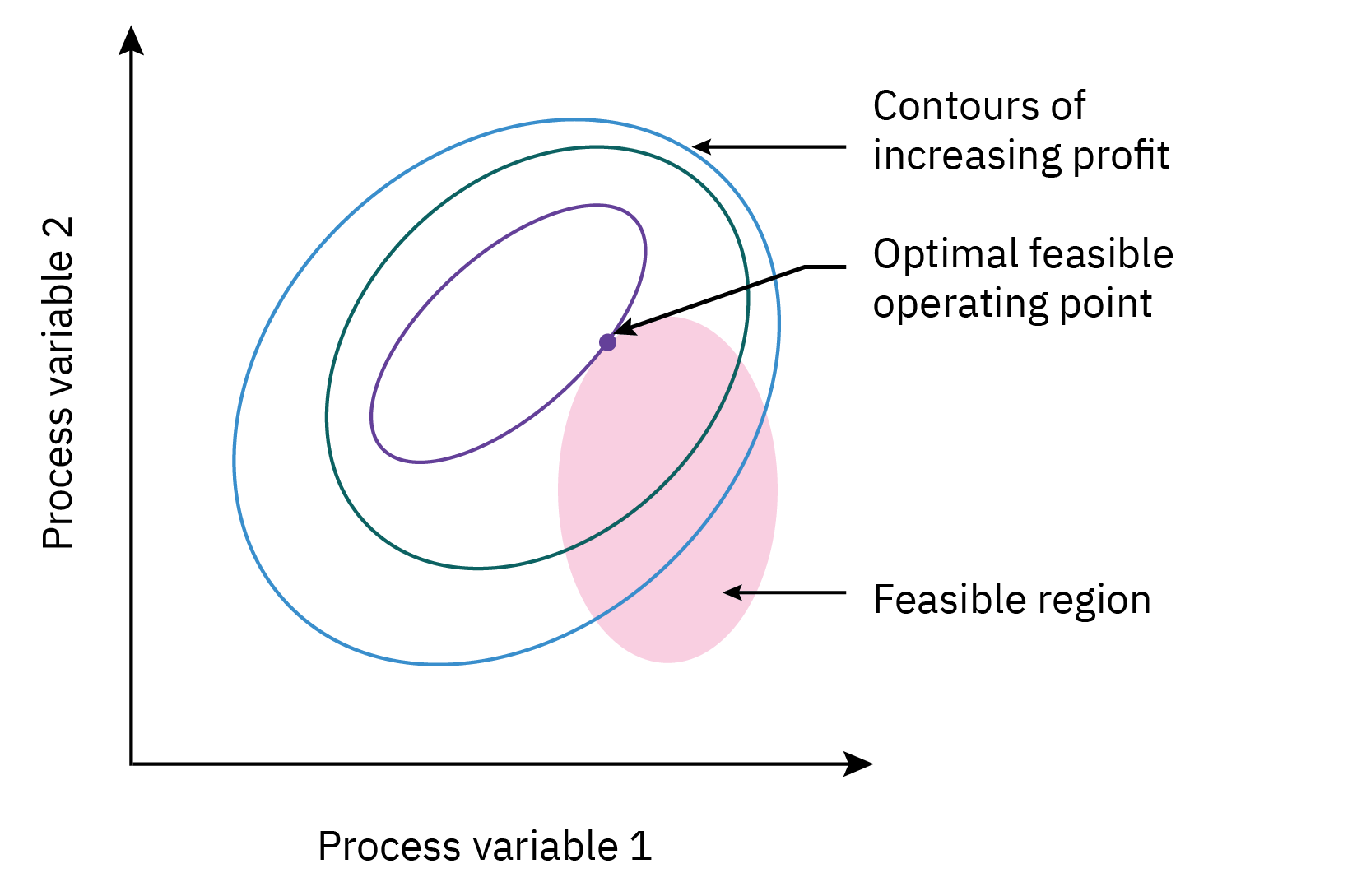

Optimal plant operations

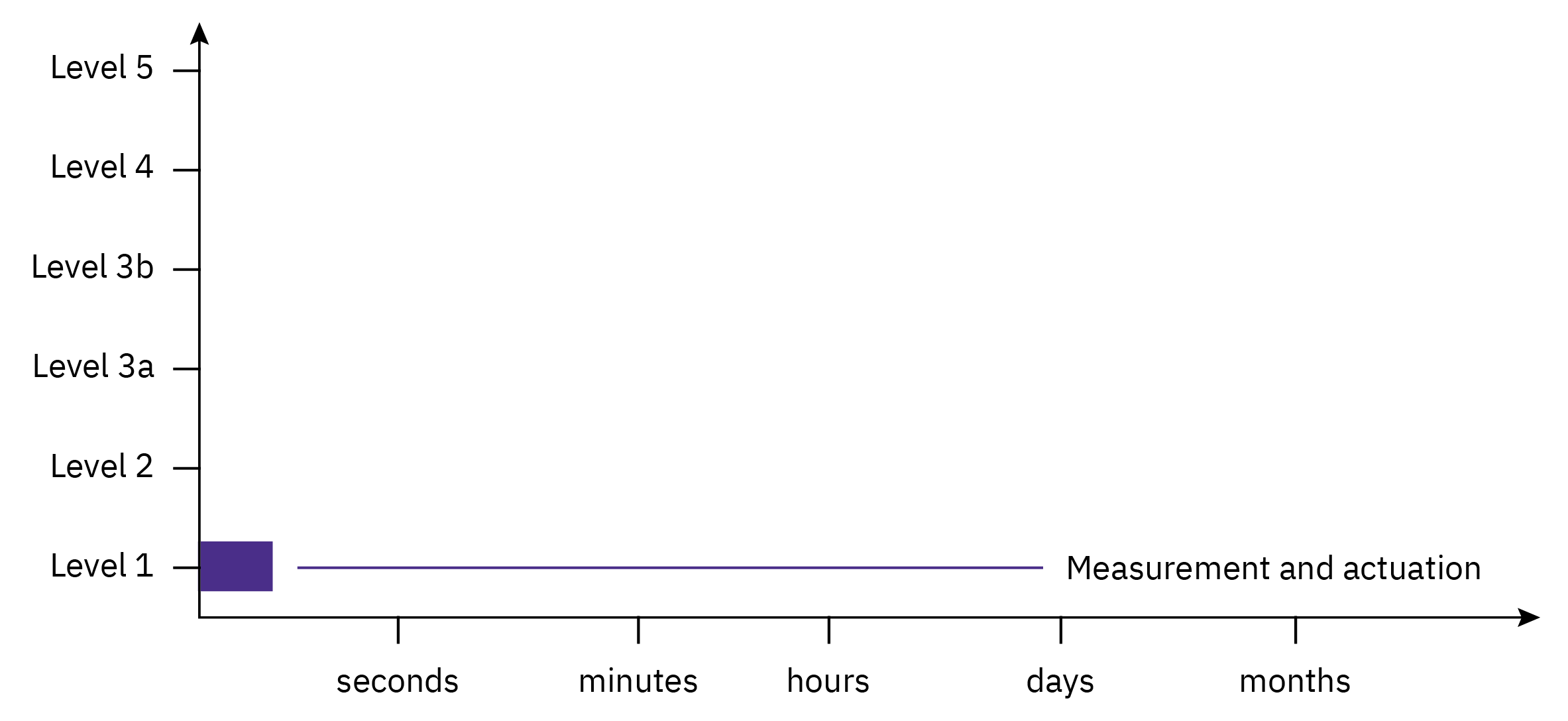

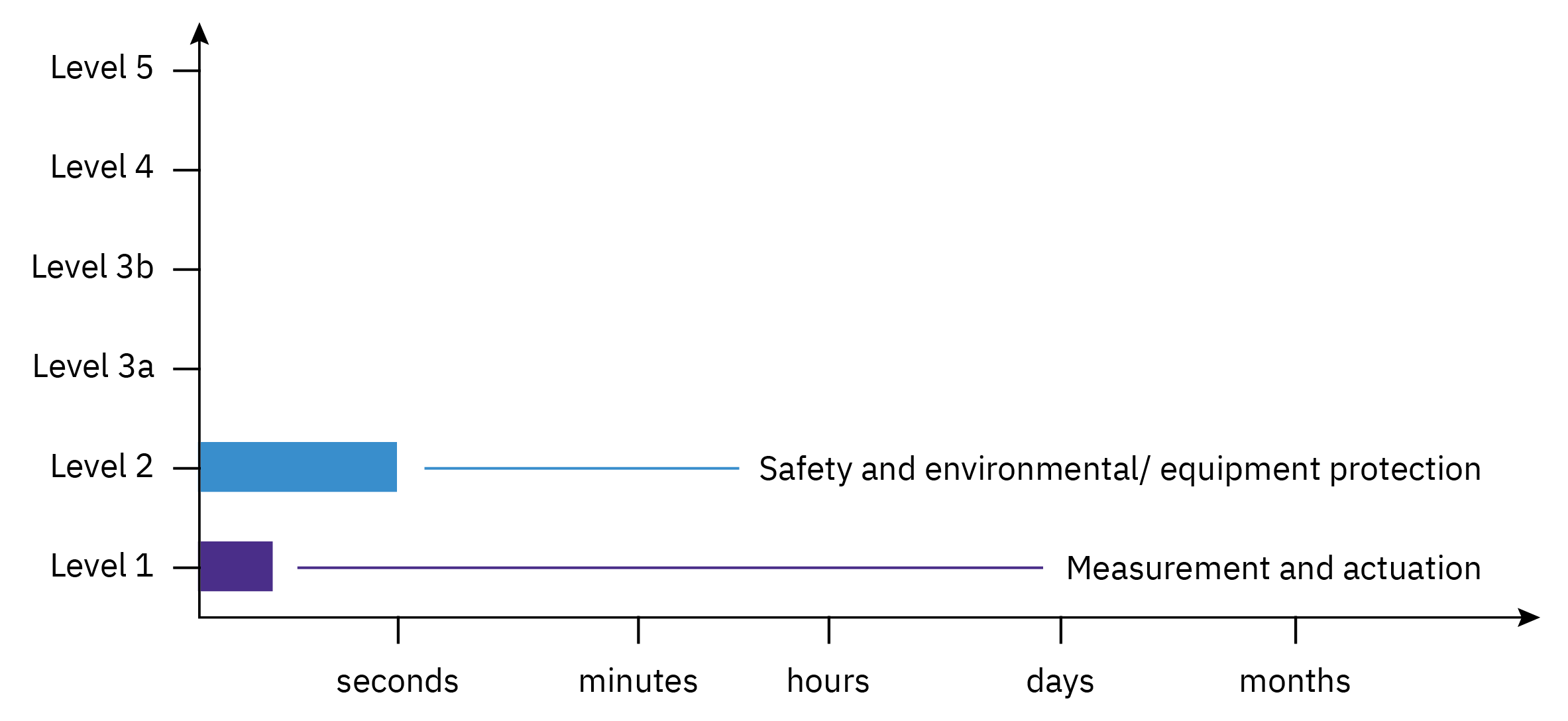

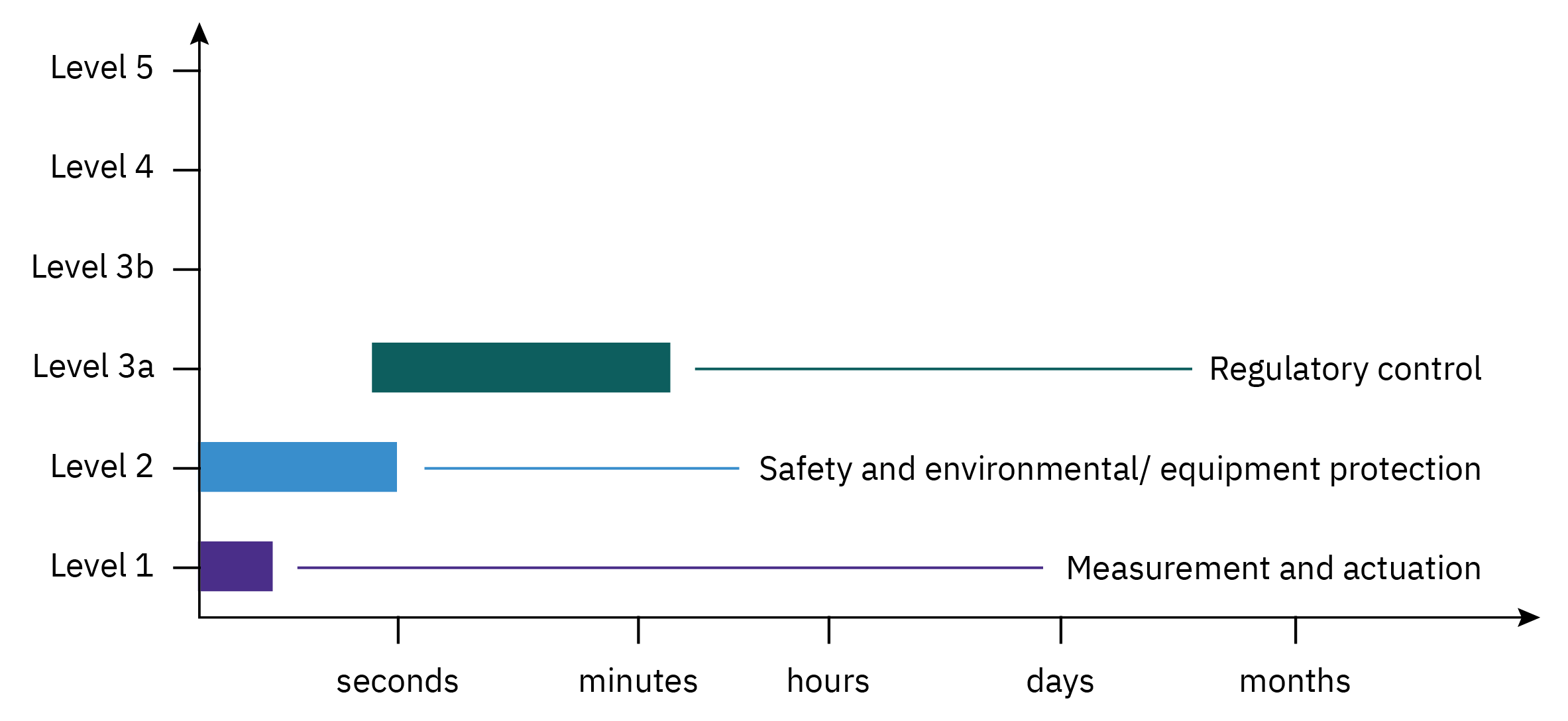

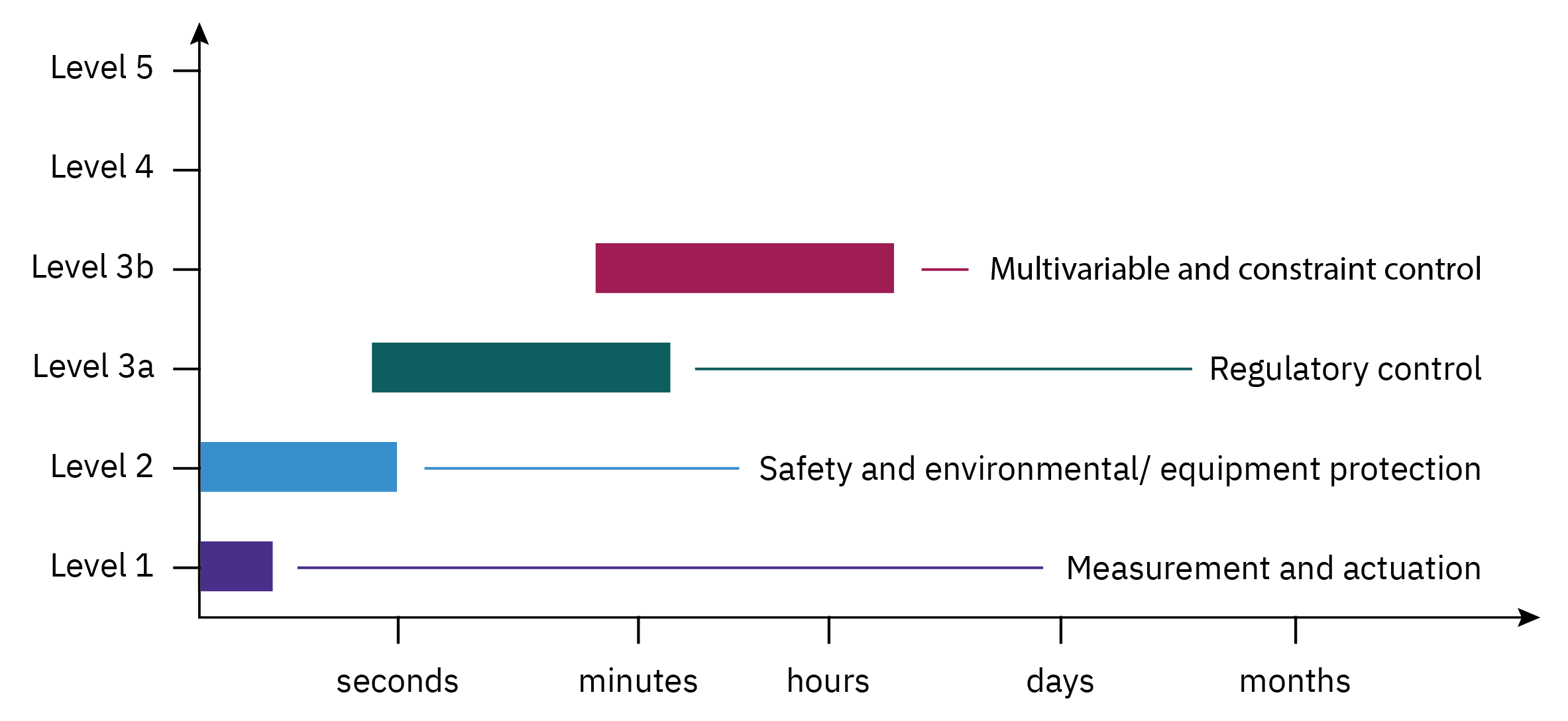

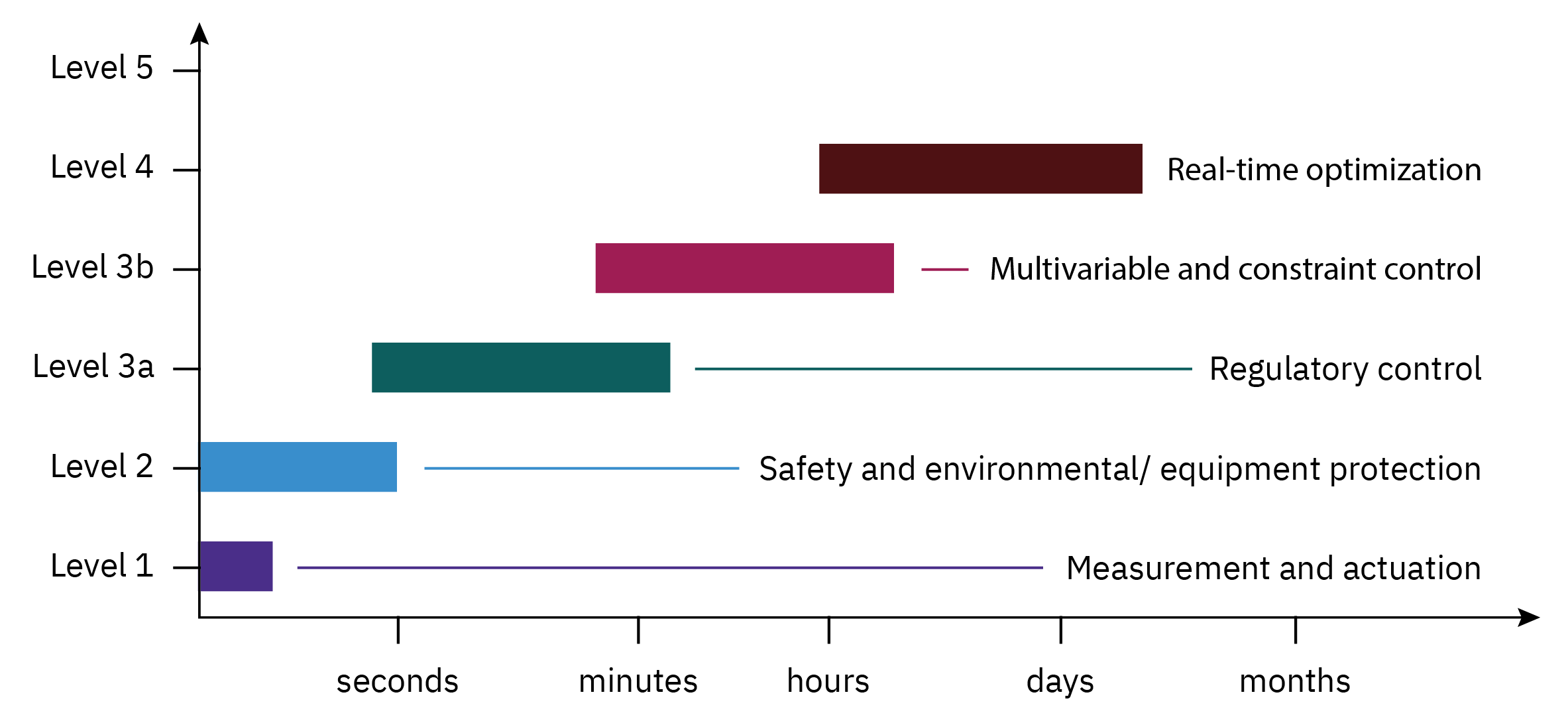

Hirarchy of process control activities

Overview of control system design

Fundamentals of process modeling

- Why process modeling?

- Types of process models

- Basic principles of mass and energy balances

- Process control terminology

Why process modeling?

Enhancing Process Understanding

Enable study of transient behavior without disruption

Provide valuable insights into dynamic and steady-state process behavior

Useful even before plant construction

Process Simulators for Training

Essential for training plant operators in complex units and emergencies

Create a realistic training environment when connected to process control equipment

Facilitating Evaluation of Control Strategies

Assist in identifying variables to be controlled and manipulated

Aid in preliminary controller tuning

Play an explicit role in model-based control strategies

Optimization of Operating Conditions

Recalculation of optimum conditions maximizes profit or minimizes costs

Utilize steady-state process model and economic data

Allow for continuous enhancement of process performance

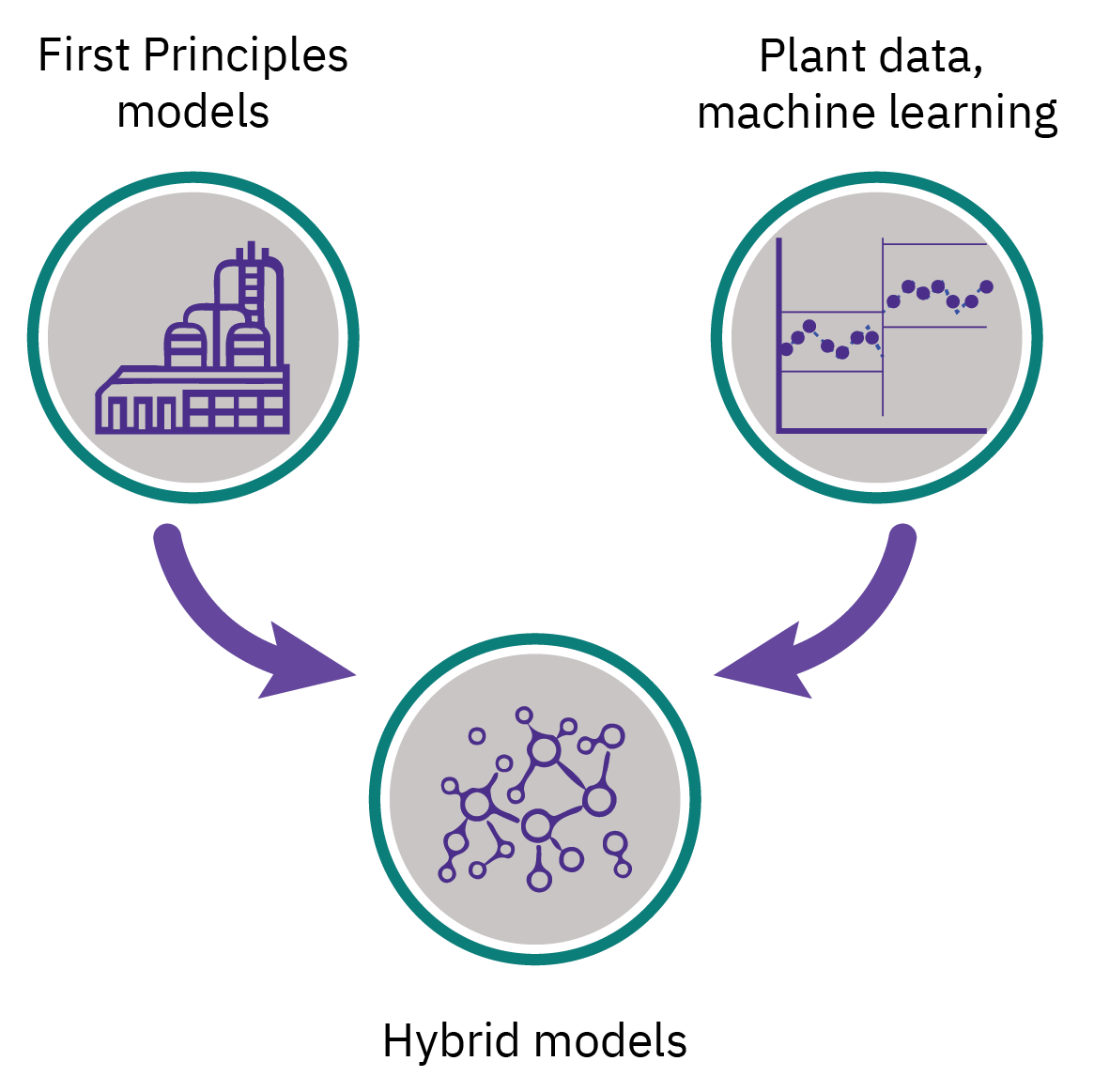

Types of process models

Theoretical models

Developed using the principles of chemistry, physics, and biology.

First principles models

Mass, momentum, and heat balances

Empirical models

Obtained by fitting experimental data.

Statistical models

Correlations

data driven models

Semi-empirical/ hybrid models

A combination of the theoretical and empirical models

The numerical values of one or more of the parameters in a theoretical model are calculated from experimental data.

Basic principles of mass and energy balances

In general

accumulation=in−out−reaction−tranfer

Mass balance (without reaction and transfer)

{rate of massaccumulation}={rate ofmass in}−{rate ofmass out}

For component i (with reaction term included)

⎩⎨⎧rate ofcomponent iaccumulation⎭⎬⎫=⎩⎨⎧rate ofcomponent iin⎭⎬⎫−⎩⎨⎧rate ofcomponenti out⎭⎬⎫+⎩⎨⎧rate ofcomponent iproduced⎭⎬⎫

Basic principles of mass and energy balances

- Energy balance

{ rate of energy accumulation }={ rate of energy in by convection }−{ rate of energy out by convection }+⎩⎨⎧ net rate of heat addition to the system from the surroundings ⎭⎬⎫+⎩⎨⎧ net rate of work performed on the system by the surroundings ⎭⎬⎫

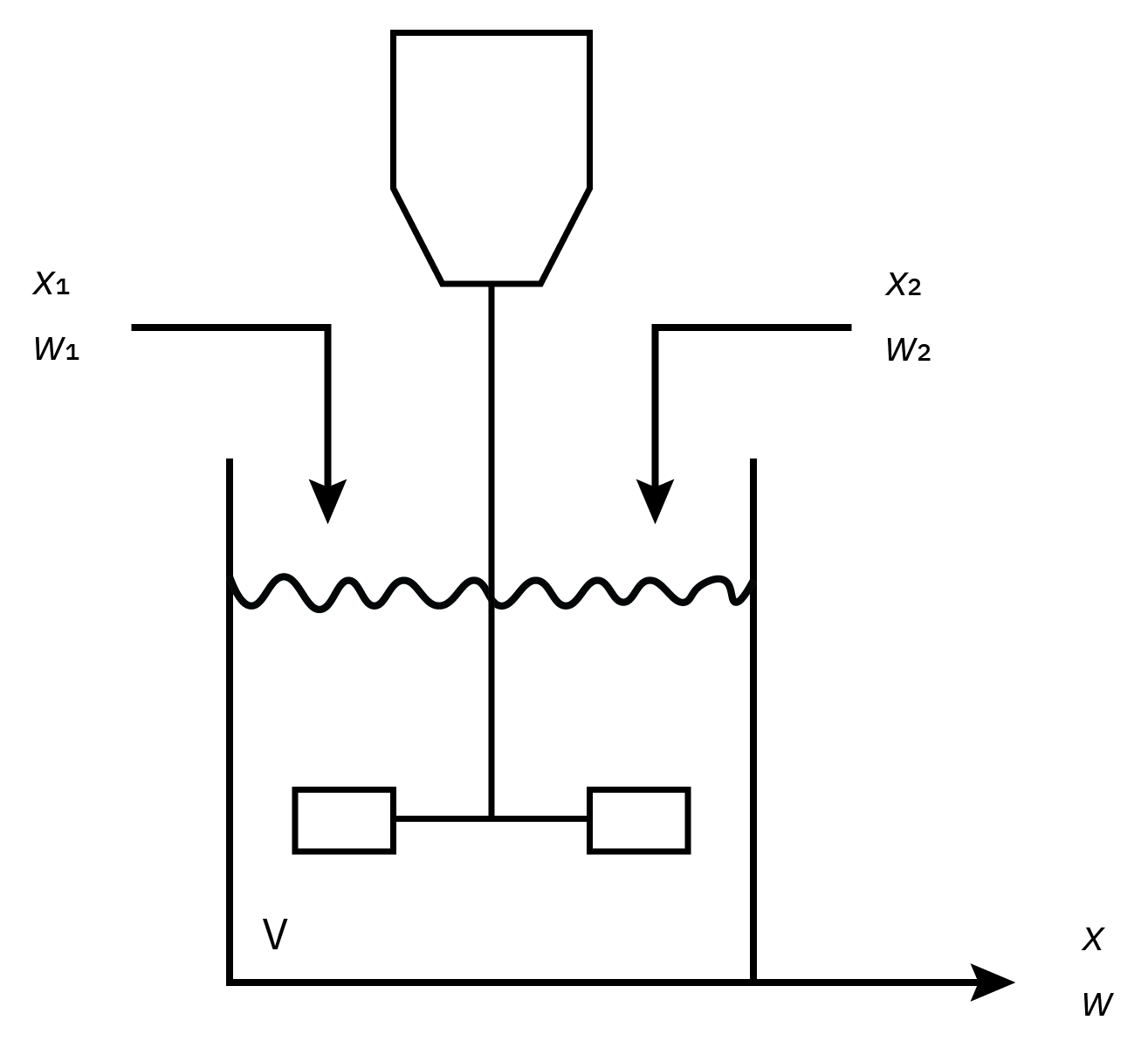

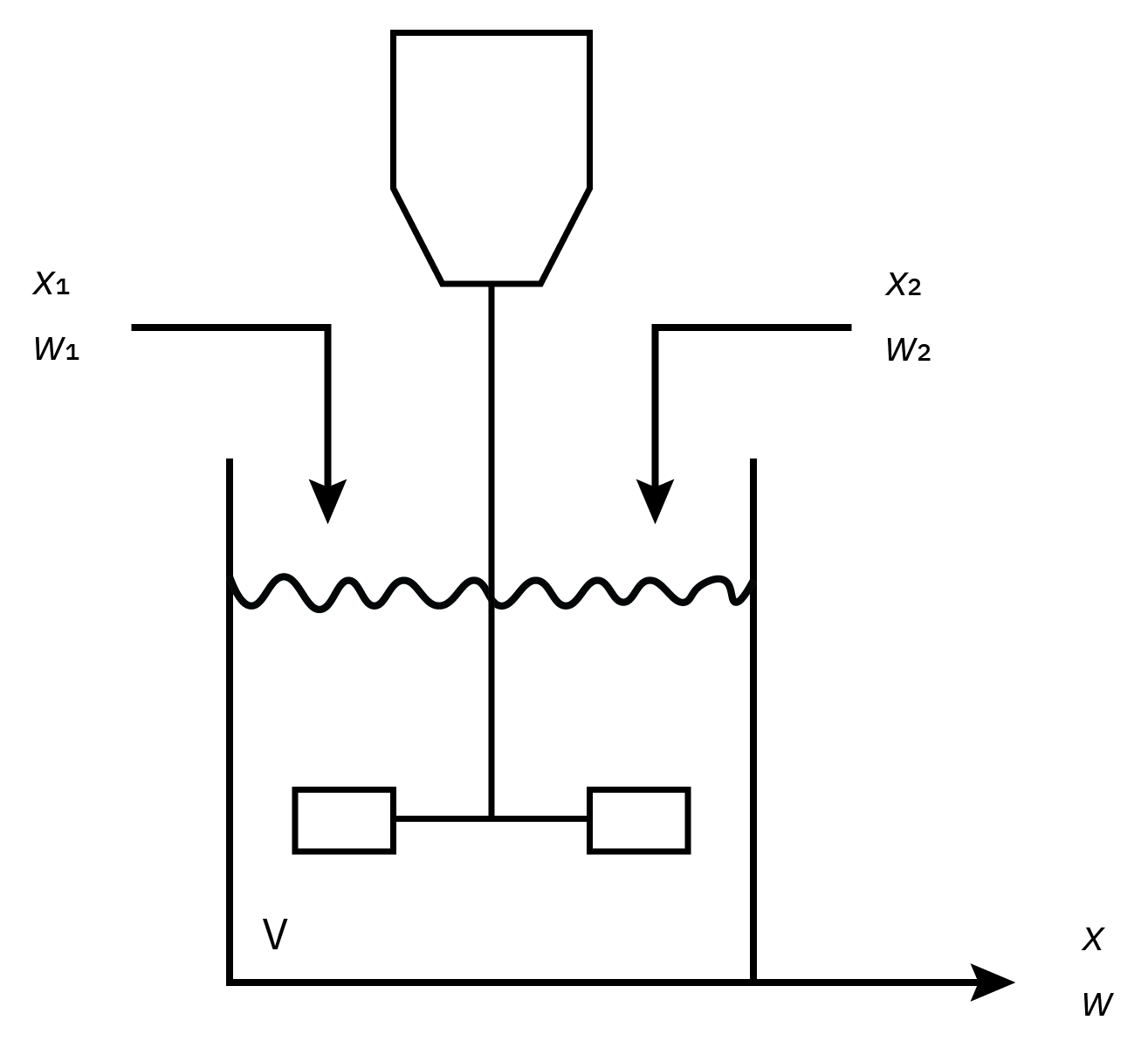

Blending of two components

Overall mass balance

{rate of accumulationof mass in the tank}={rate ofmass in}−{rate ofmass out}

dtd(Vρ)=w1+w2−w

Component balance

dtd(Vρx)=w1x1+w2x2−wx

Blending of two components

Overall mass balance

{rate of accumulationof mass in the tank}={rate ofmass in}−{rate ofmass out}

dtd(Vρ)=w1+w2−w

Component balance

dtd(Vρx)=w1x1+w2x2−wx

It is possible to further simplify the system of two differential equations to

dtdV=ρ1(w1+w2−w)

dtdx=Vρw1(x1−x)+Vρw2(x2−x)

Degrees of freedom analysis

- To simulate a process, it’s crucial to confirm that the model equations, both differential and algebraic, form a set of relations that can be solved.

- For the model to have a unique solution, the number of unknown variables should match the number of independent model equations.

NF=NV−NE

- NF=0: The process model is exactly specified. If NF=0, then the number of equations is equal to the number of process variables and the set of equations has a solution. (However, the solution may not be unique for a set of nonlinear equations.)

- NF>0: The process is underspecified. If NF>0, then NV>NE, so there are more process variables than equations. Consequently, the NE equations have an infinite number of solutions, because NF process variables can be specified arbitrarily.

- NF<0: The process model is overspecified. For NF<0, there are fewer process variables than equations, and consequently the set of equations has no solution.

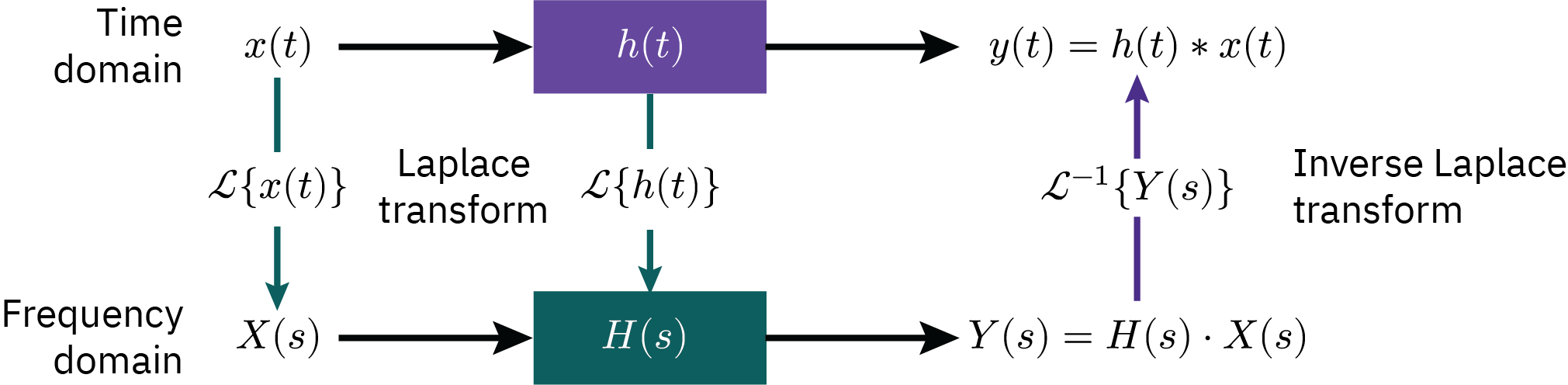

Solution of model equations

Nonlinear Chemical Processes: These result in complex ordinary differential equations when modeled.

Linear System Controls: These tools are well-established and provide valuable insights when processes operate near a specific point.

Laplace Transform: This simplifies creation of input-output models by converting differential equations to algebraic ones.

Transfer Function: An essential tool in control system design and analysis, representing linear control theory.

Empirical models

We can construct an empirical model using plant data

Assume a certain idealized model structure

First-order plus deadtime (FOPDT) model

Time domain form τpdtdy(t)+y(t)=Kpu(t−θp)

Frequency domain form (transfer function) Gp(s)=τps+1Kpe−θps

Kp: Process gain; τp: time constant; θp: deadtime

FOPDT model is often used in controller tuning. A transfer function is a mathematical formula that describes how a system responds to different inputs over time.

Second-Order plus Deadtime (SOPDT) Model

Time domain

τ2dt2d2y(t)+2ξτdtdy(t)+y(t)=Kpu(t−θ)

Frequency domain

Gp(s)=U(s)Y(s)=τ2s2+2ξτs+1Kpe−θs

Kp: Process gain; τ: time constant; θ: dead time; ξ: damping factor or coefficient

Behavior:

ξ>1: Overdamped

0<ξ<1: Underdamped

ξ=1: Critically damped

ξ=0: Sustained oscillations

ξ<0: Unstable

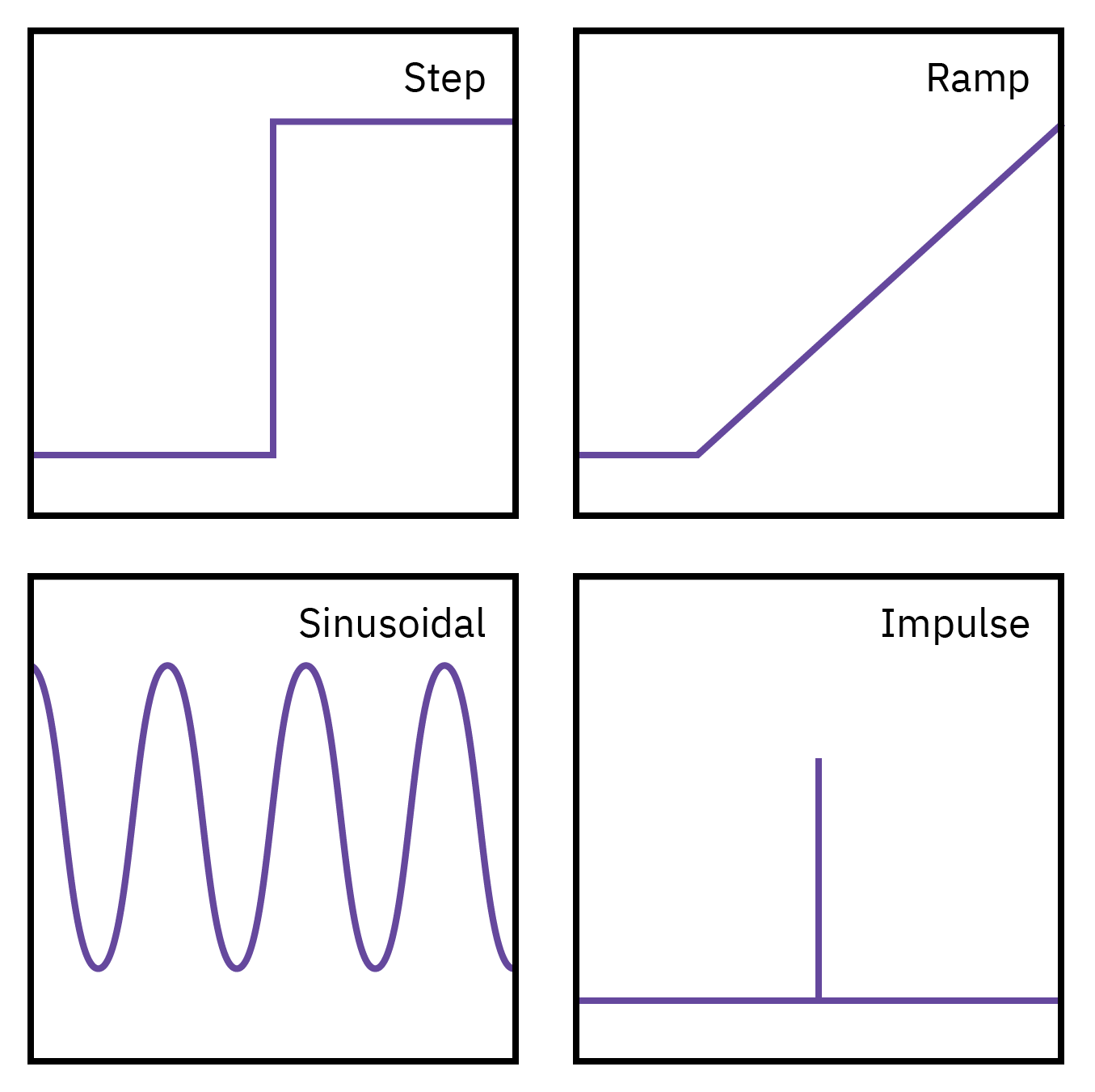

Dynamic Behavior of Processes

- Input types

- Response of first-order systems

- Response of second-order systems

- Properties of transfer functions

- Stability of linear systems

Input types

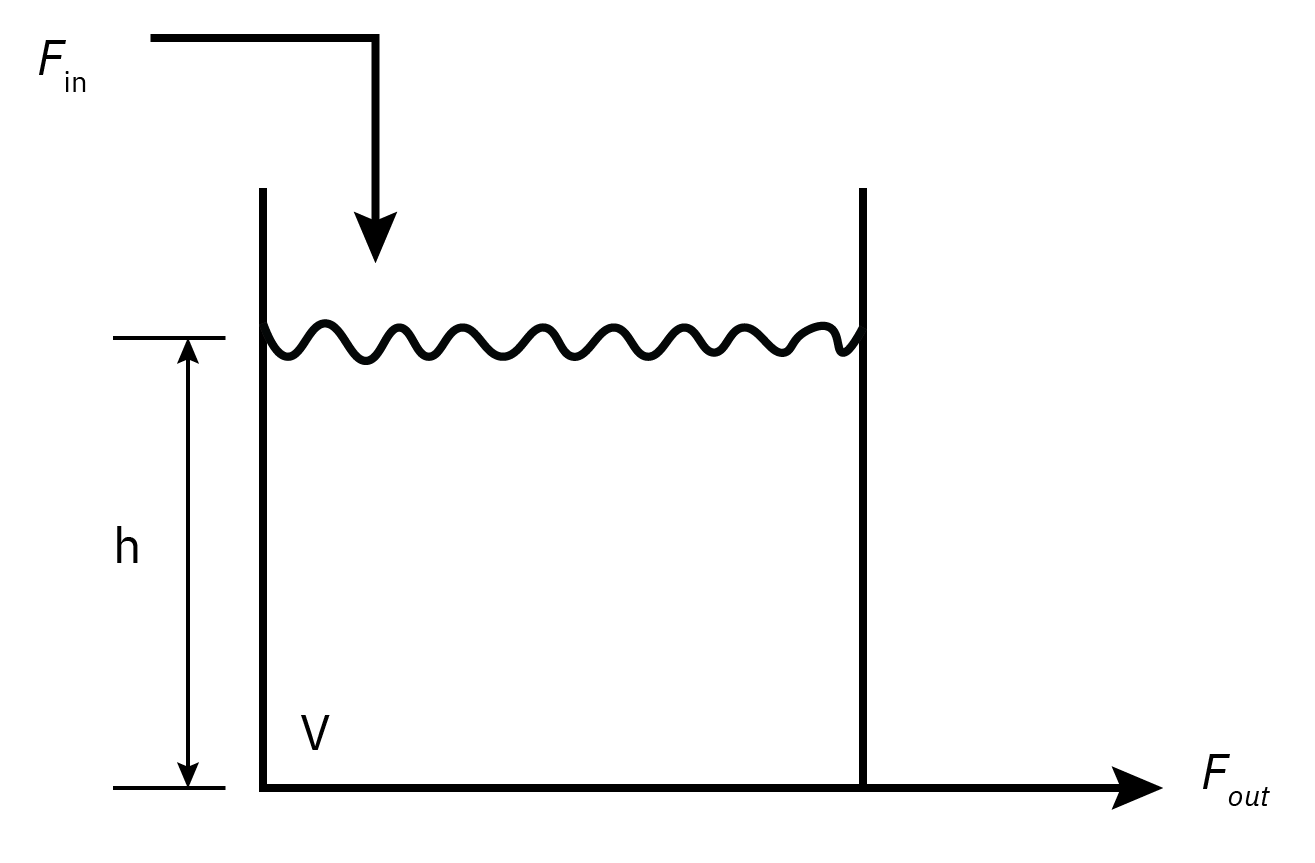

Response of first-order systems

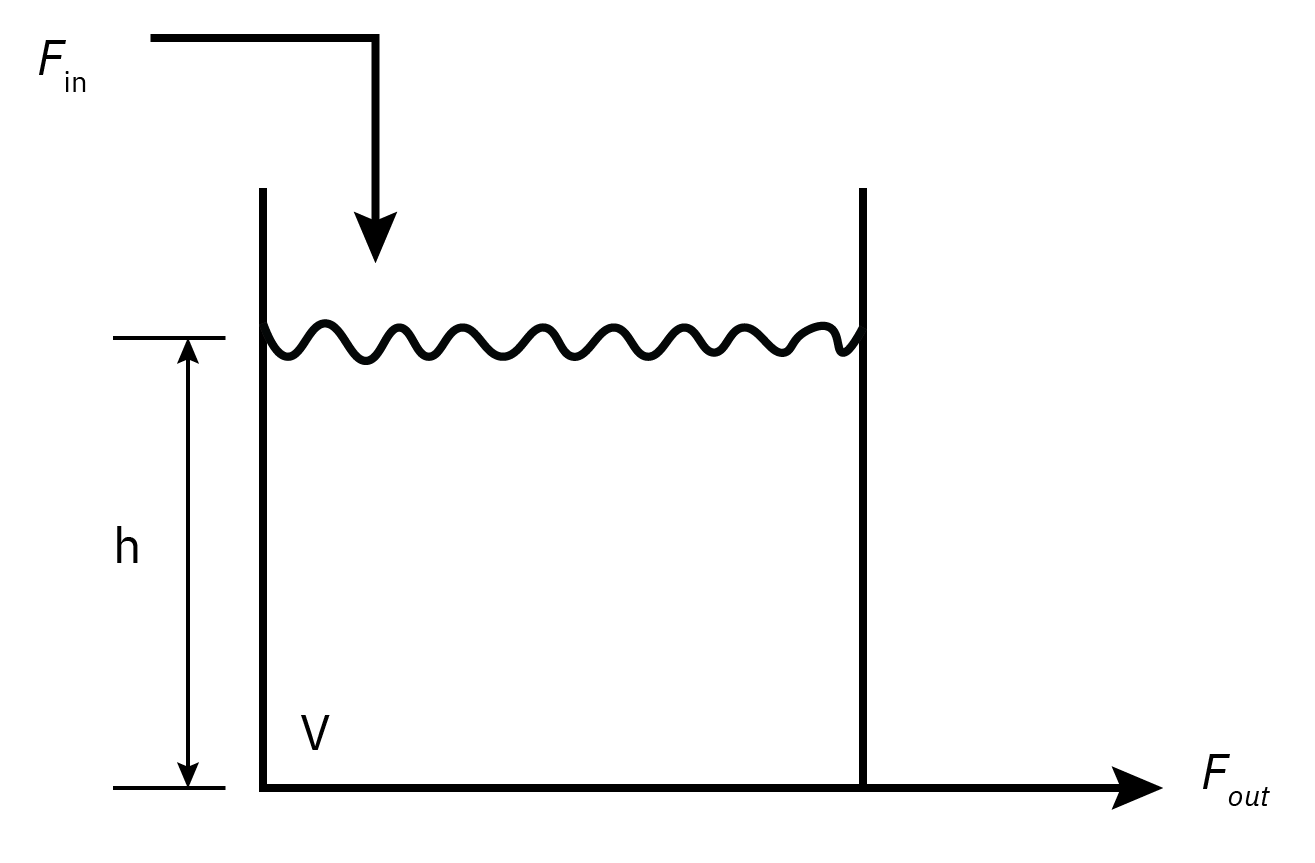

Overall mass balance

Adtdh=Fin−Fout

Outlet flow rate, Fout has a square-root dependence on liquid level Fout=βh

Resulting nonlinear equation

Adtdh=Fin−βh

τdtdhˉ+hˉ=kFin;τ=β2Ah;k=β2h

Transfer function

Finˉ(s)hˉ(s)=g(s)=τs+1k

Process gain (k): Ultimate value of the response (new steady-state) for a unit-step change in the input.

Time constant (τ): Time necessary for the process to adjust to a change in the input.

Response of first-order systems

The ultimate (steady-state) value of the response, hˉ(t→∞), is equal to k for a unit-step change.

When the elapsed time is equal to the process time constant t=τ, the system reaches 63.2% of its final response.

After approximately 5τ, the transient response can be considered as having reached steady-state.

For a given t / τ, the output reaches the same fraction of the ultimate output response value.

In a tank process, a rise in the inlet flow rate elevates the liquid level, which in turn increases the hydrostatic pressure and subsequently the outlet flow rate. The system eventually reaches a new steady state. This feature is termed ‘self-regulation’.

Response of first-order systems

Response of second-order systems

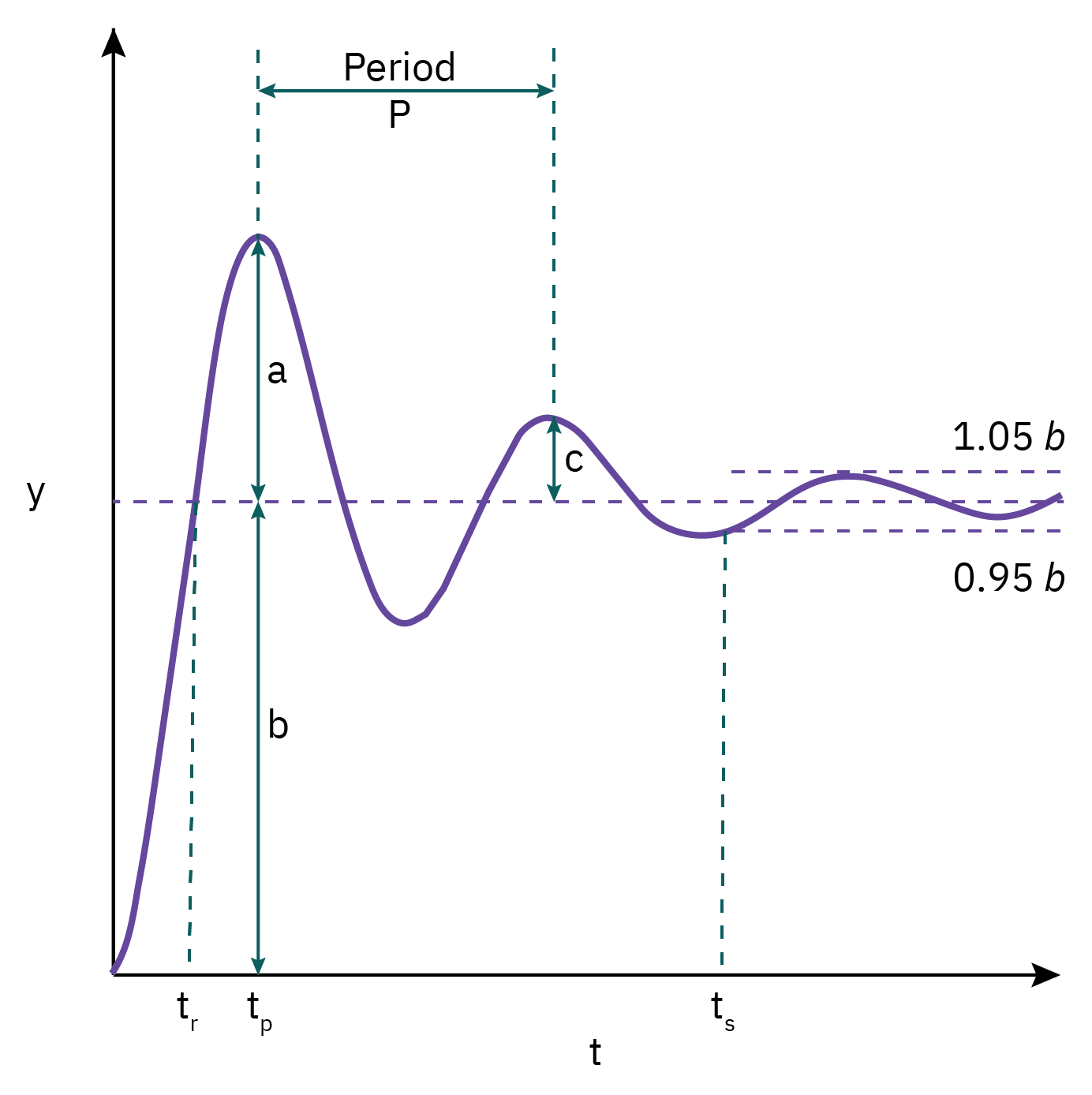

Rise time (tr): time required for y(t) to first cross its new steady state value

Overshoot (a/b): The maximum amount by which the response exceeds the new steady state value

Decay ratio (c/a): Ratio of the height of successive peaks in the response

Period of oscillation (P): time for a complete cycle

Response/ settling time (ts): time required for the response to remain within a ± 5% band based upon steady state value.

Decay ratio, overshoot, response time, and damping factor (ξ) can be used as a basis for tuning.

Response of second-order systems

Critically damped (ξ = 1)

Output response becomes more sluggish as τ increases.

The responses are qualitatively similar.

Effect of ξ

ξ < 1: Oscillation and overshoot

ξ > 1: Sluggish response, no oscillations; no overshoot

ξ = 1: Fastest response, no oscillations; no overshoot

Properties of transfer functions

For transfer function

g(s)=u(s)y(s)=a0sn+…+anb0sm+…+bm=p(s)z(s)

The roots of the polynomial z(s) are the zeros of the transfer function or the zeros of the process.

The roots of the polynomial p(s) are the poles of the transfer function or the poles of the process.

A physical system needs to be proper (n≥m), and casual (output depends only on past inputs)

Characteristic equation

The denominator polynomial p(s) when equated to zero is called the characteristic equation:

p(s)=a0sn+…+an=0

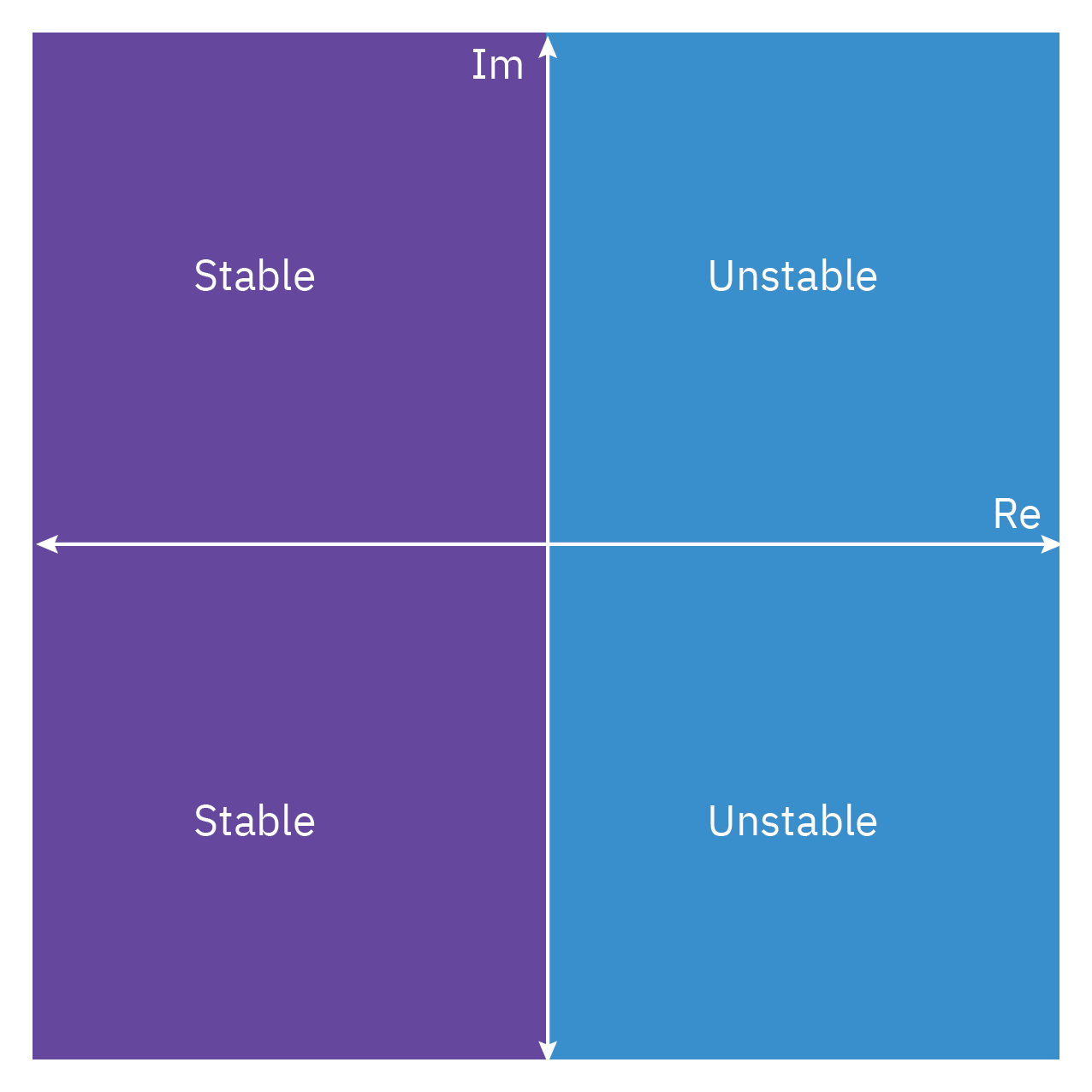

Stability of linear systems

- The location of the poles of a transfer function determines the bounded input–bounded output (BIBO) stability of a process.

- If the transfer function of a dynamic process has a pole with a positive real part, the process is unstable. If the real part is zero, then the process is critically stable

- We need to be cautious when we derive a transfer function model from a statespace model, because a zero (or zeros) may cancel a pole (or poles). This becomes especially important if the canceled pole is unstable, which means that those modes of the process would be hidden from us.

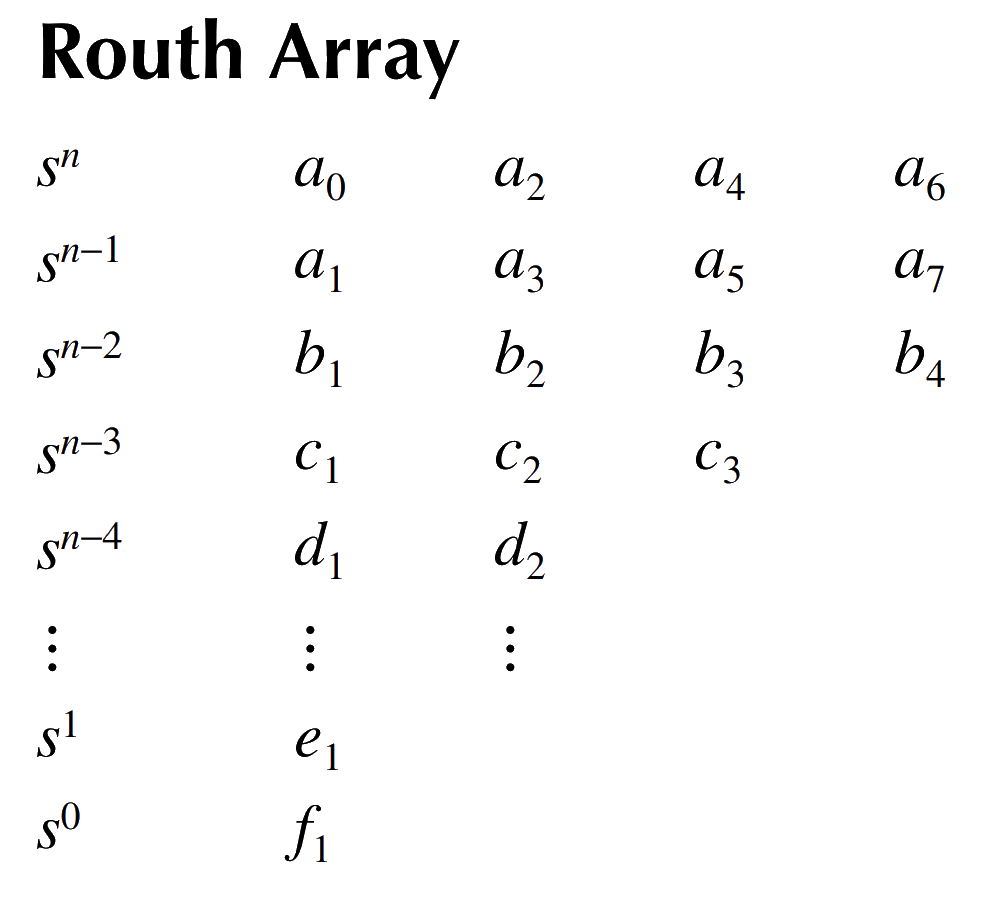

Routh’s Stability Criterion

Routh’s Criterion is a mathematical test that is used to determine whether a linear system is stable or unstable. It does not require explicit calculation of the roots of the characteristic equation.

Characteristic equation

a0sn+a1sn−1+a2sn−2+⋯+an=0

The first step in Routh’s Criterion is to set up the Routh array.

Then, we examine the first column of the array. If there are no sign changes in the first column, the system is stable.

If there are sign changes in the first column, the system is unstable. The number of sign changes corresponds to the number of roots with positive real parts.

Routh’s Criterion can also be used to determine relative stability and system type.

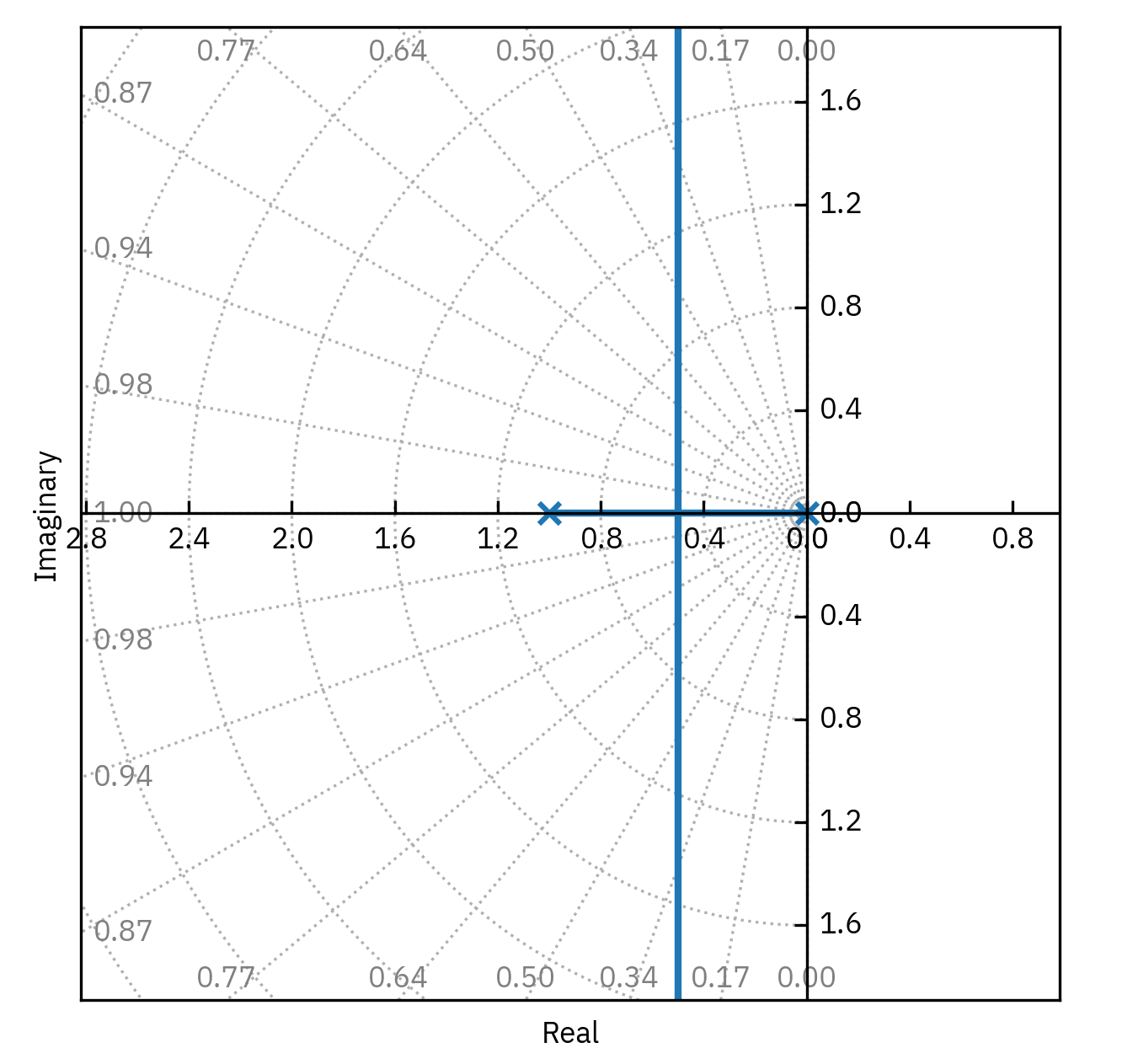

Root locus method

Root Locus is a graphical method used in control systems to examine how the system stability changes with varying gain.

It shows possible pole locations as system gain varies from zero to infinity.

The method provides insights into stability and transient response.

Root locus begins at open-loop poles and ends at open-loop zeros.

The plot exists on parts of the complex plane where the number of open-loop poles and zeros to the right is odd.

Consider the characteristic equation p(s,k)=s2+s+k=0

Feedback Control Systems

- Introduction to feedback control

- Control law

- Proportional, integral, and derivative control actions

- Further topics

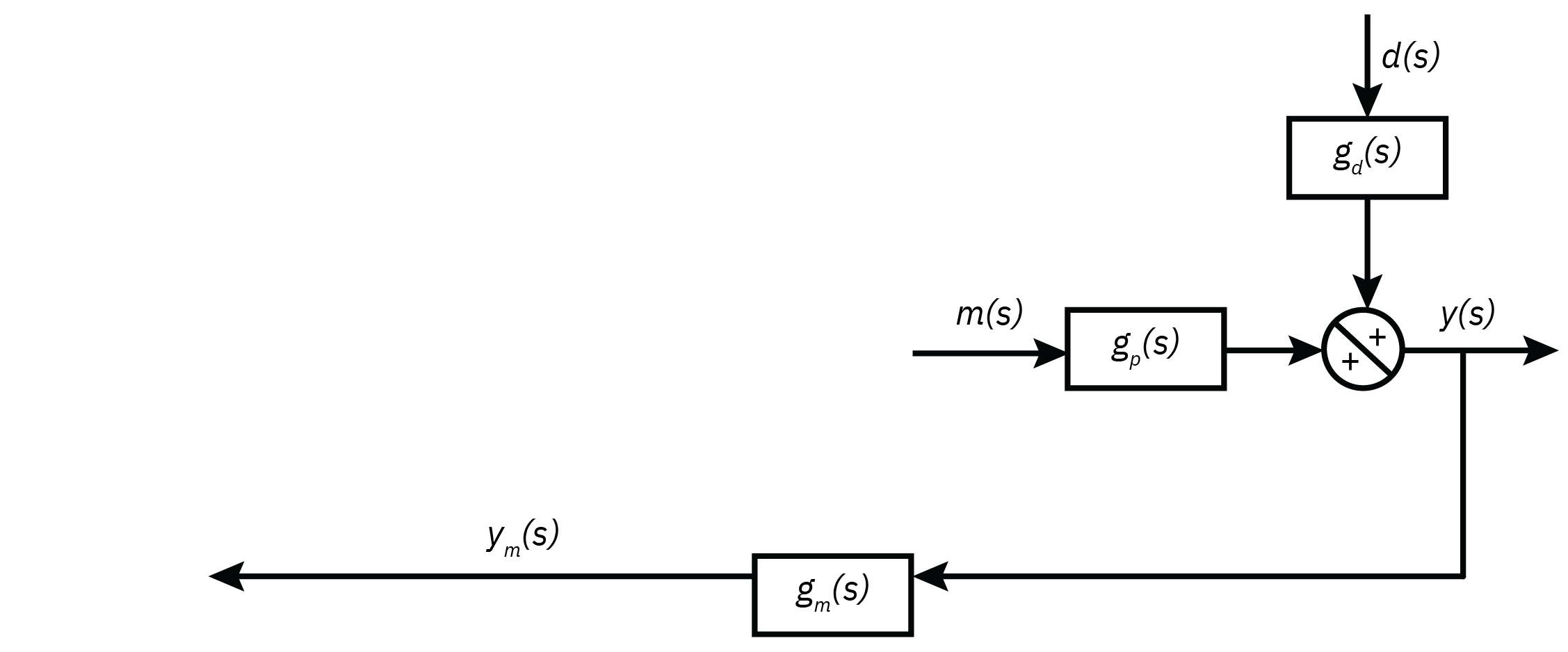

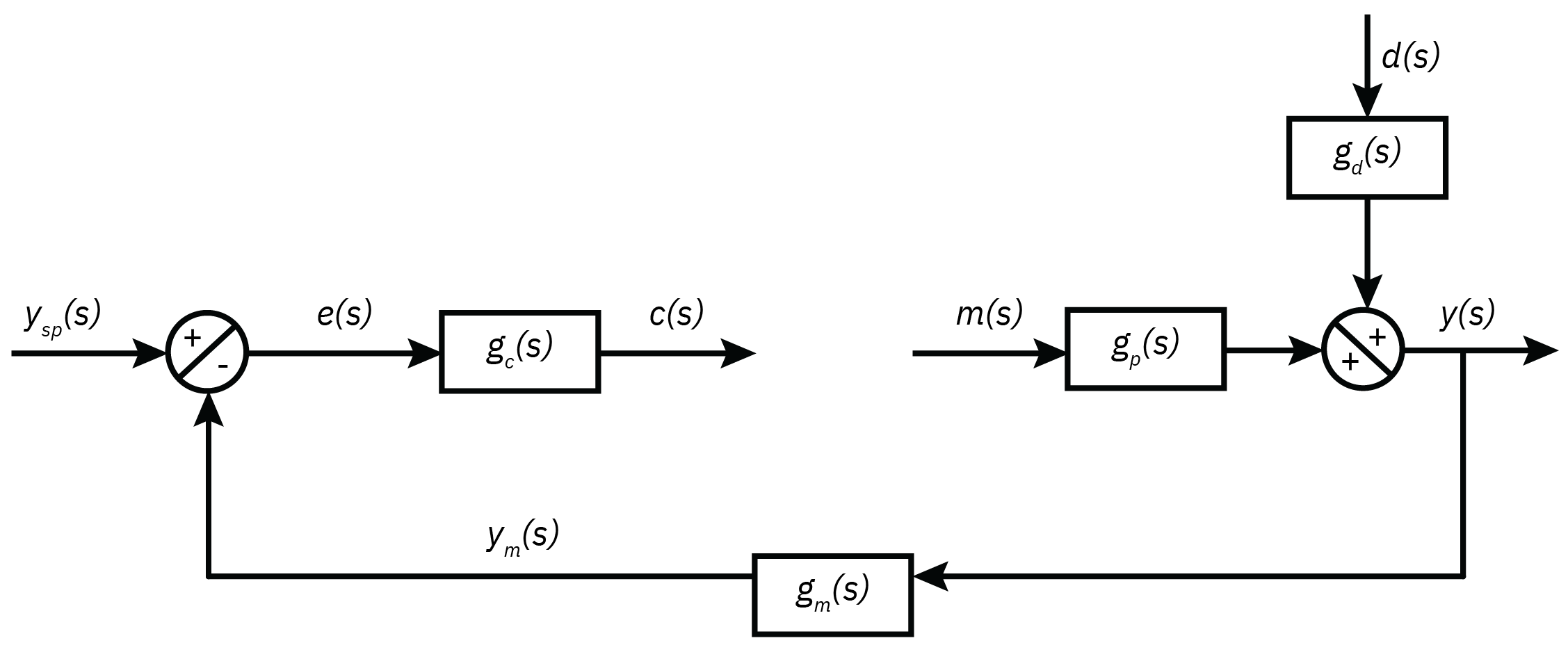

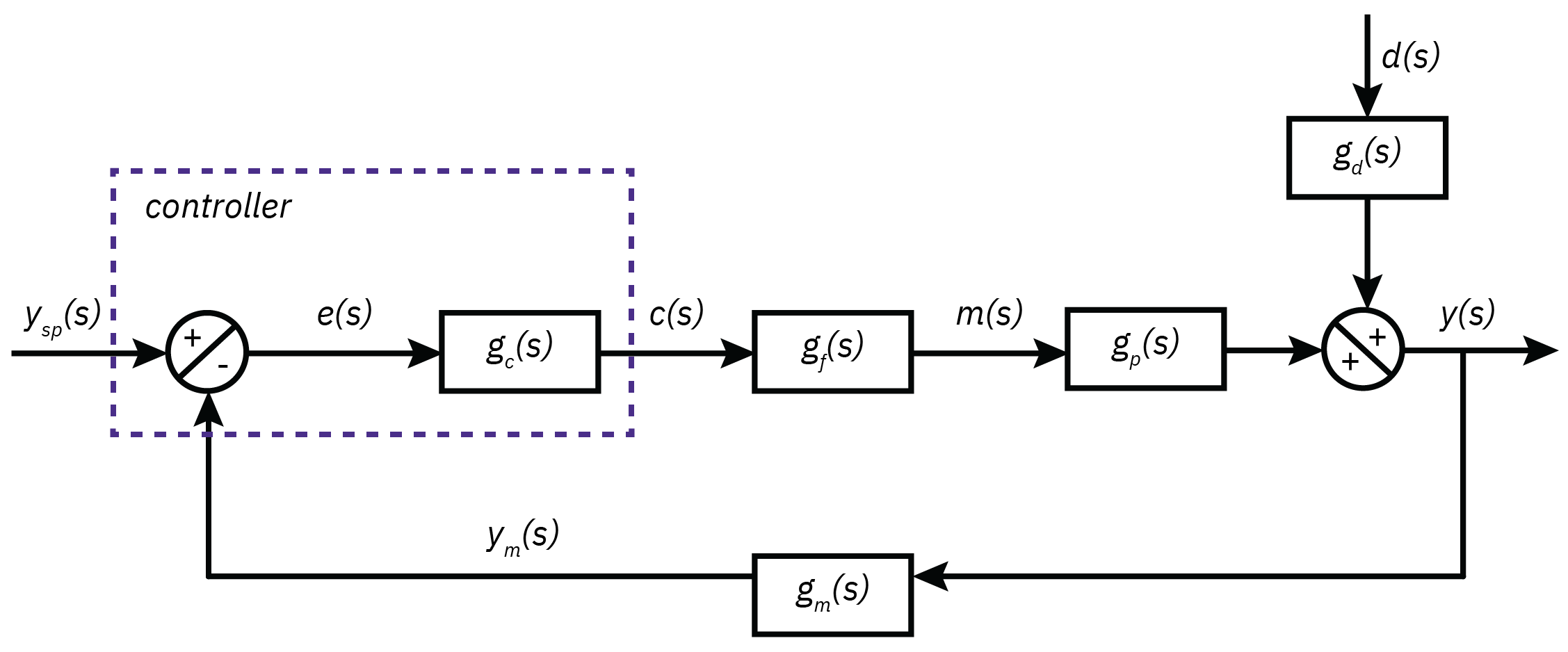

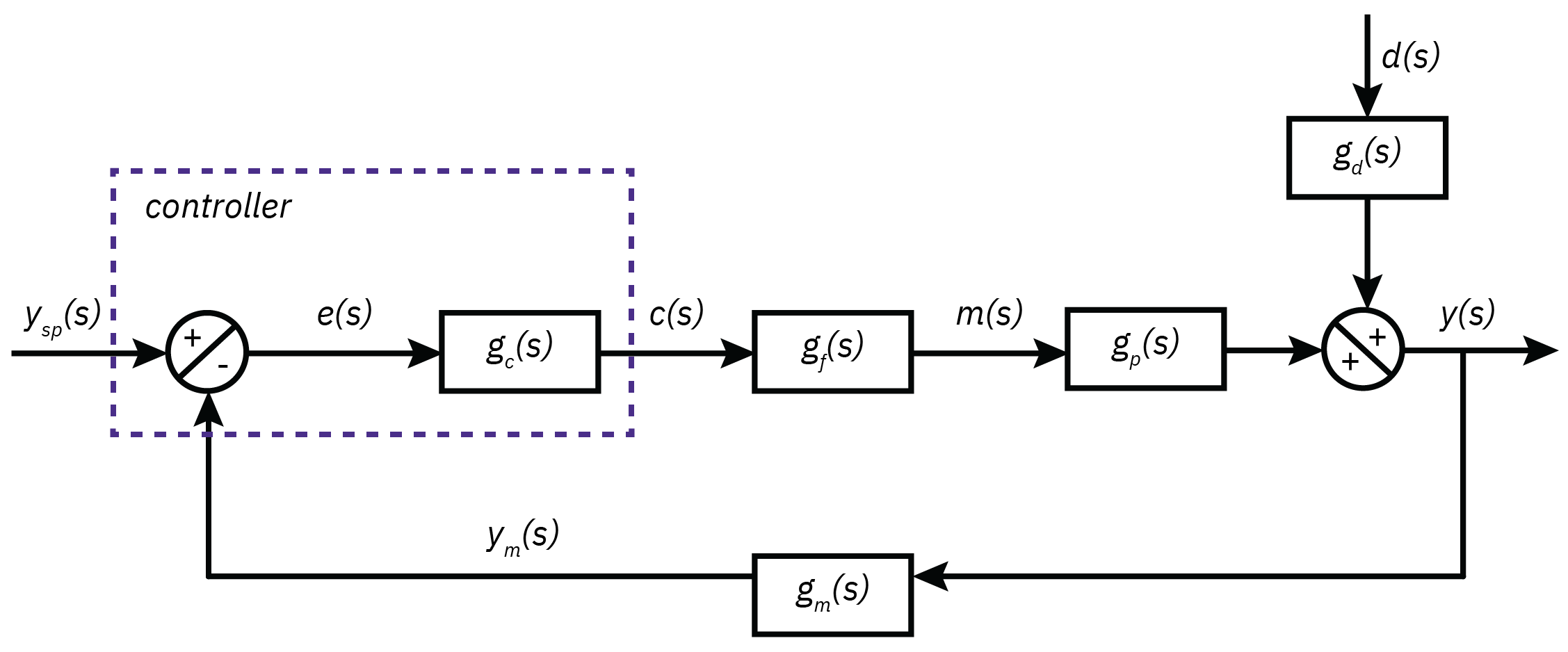

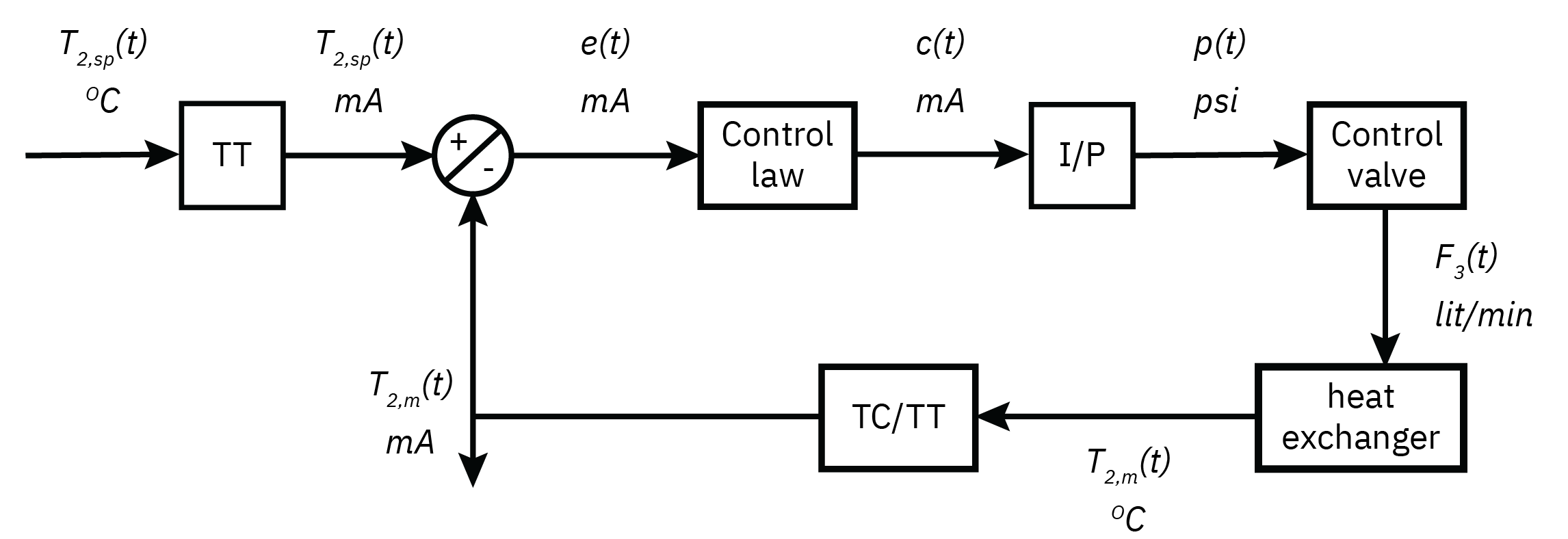

Introduction to feedback control

Introduction to feedback control

y=gpm+gdd

Error: e=ysp−ym

Control action: c=gce=gc(ysp−ym)

Manipulated variable: m=gfc=gcgf(ysp−ym)

Controlled variable: y=gpm+gdd=gcgfgp(ysp−ym)+gdd

Closed loop transfer function y=1+gpgfgcgmgpgfgcysp+1+gpgfgcgmgdd

Introduction to feedback control

y=Gspysp+Gdd

Gsp embodies the dynamics of the setpoint response.

How the process output will respond when the set-point is changed?Gd(s) indicates how the process output will respond when a disturbance enters the process.

Denominators of the closed-loop transfer functions, Gsp and Gd, are the same, indicating that they share the same stability characteristics.

In a more general setting, the closed-loop transfer function for general block diagram is represented as

ri(s)r(s)=1+G2(s)G1(s)

In this expression, r is an output variable or any internal variable within the control loop and ri represents an input variable such as ysp or d.

The transfer function G1 is the product of the transfer functions in the forward path that connects an input ri to an output r.

G2 is the transfer function composed of all transfer functions in the feedback loop.

Introduction to feedback control

Introduction to feedback control

Control law

- The control signal c(t) is calculated, given the value of the error e(t), through a predefined functional relationship c(t)=C[e(t)]

- The function C[⋅] constitutes the control law.

- Establishes the manner with which the error information is processed by the controller.

- The most common functional form is the three-mode proportional–integral– derivative (PID) control law eˉ(s)cˉ(s)=gc(s)=kc(1+τIs1+τDs)

Proportional mode

- This mode produces a control signal that is proportional to the error: c(t)=kce(t)+cb

- kc represents the proportional gain of the controller: Defines how sensitive the controller is to errors present in the system.

- cb is a bias signal that corresponds to the value of the control signal when the error is zero. The bias signal is the steady-state value of the control signal.

- Define - deviation variable cˉ(t)=c(t)−cb; also eˉ(t)=e(t)

- Transfer function: eˉ(s)cˉ(s)=gc(s)=kc

Proportional mode

Integral mode

- The control signal for this mode is produced by the integral equation: c(t)=τIkc∫e(t)dt+cb

- The new parameter τI represents the integral time constant or the reset time.

With this mode, the controller responds effectively to errors that build up over time.

This is a very important feature because even if the error is small, as long as it persists, a large control signal may be calculated, thus helping to eliminate the error quickly

- The transfer function of a controller with only the integral mode is eˉ(s)cˉ(s)=gc(s)=kc(τIs1)

Integral mode

Derivative mode

- In this mode, the control signal responds to the rate of change of the error signal: c(t)=kcτDdtde(t)+cb

- A new parameter τD is introduced as the derivative time constant.

The role of this mode is to judge the change in the error.

For instance, if the error is still present but not increasing as fast, the controller may use this information to decrease the control signal, thus possibly avoiding overly aggressive control actions.

- The transfer function for a controller with derivative mode only is given by eˉ(s)cˉ(s)=gc(s)=kc(τDs)

Derivative mode

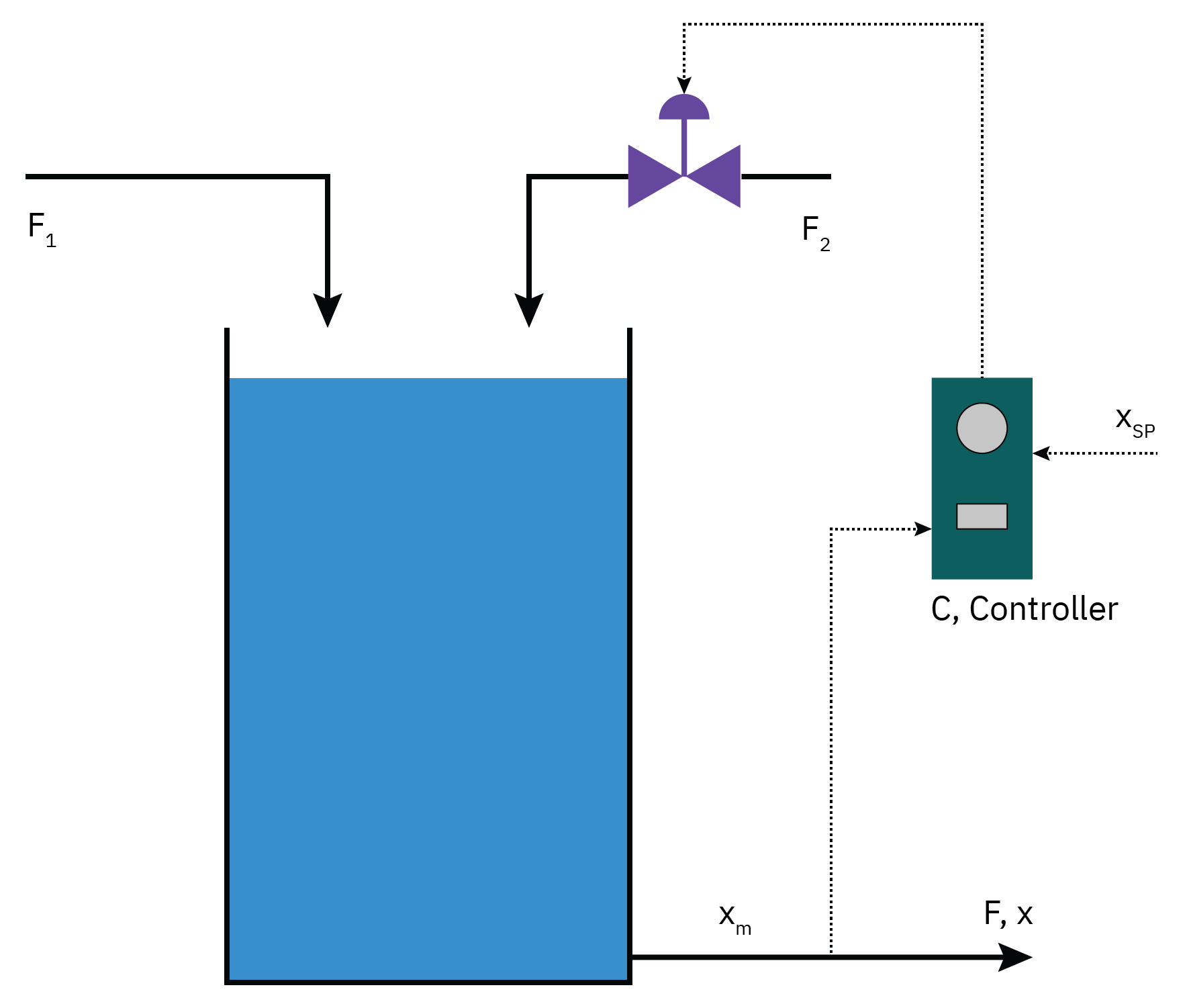

Mixing tank

The manipulated variable is the flow rate of stream 2, F2, to control the outlet mass fraction, x.

The disturbance is the flow rate of stream 1, F1.

The feed mass fractions are assumed constant.

There is a P controller, gc(s)=kc.

The dynamics of the actuators and the sensors are accounted for by pure dead-time elements, resulting in the transfer functions

xˉ(s)=2.5s+1−0.1e−sFˉ1(s)+2.5s+10.1e−sFˉ2(s)

Mixing tank: setpoint change

Mixing tank: disturbance rejection

Further topics

Model liniarization

Controller design and tuning methods

Frequency response analysis

Bode plots and Nyquist plots

Advanced Modeling and Control